Innovation that works for you

AI makes your data work harder: more figures, more findings, and much more efficient processes. The dynamic power of AI marks a huge shift in operational capabilities. It’s time to seize on this potential.

By leveraging its extensive expertise of heavy industry processes and advanced AI technologies, Voith delivers bold AI-powered solutions in multiple fields such as predictive maintenance. These enhance overall equipment effectiveness and minimize costs – all while maintaining the highest data security standards.

OnCare.InSight can be used for predictive maintenance in all Voith Turbo industries:

- Power, Oil & Gas

- Petrochemical

- Steel and mining

Key benefits of Voith AI solutions

Expertise and innovation

Human-AI collaboration

Proactive problem solving

Versatility across industries

OnCare.InSight

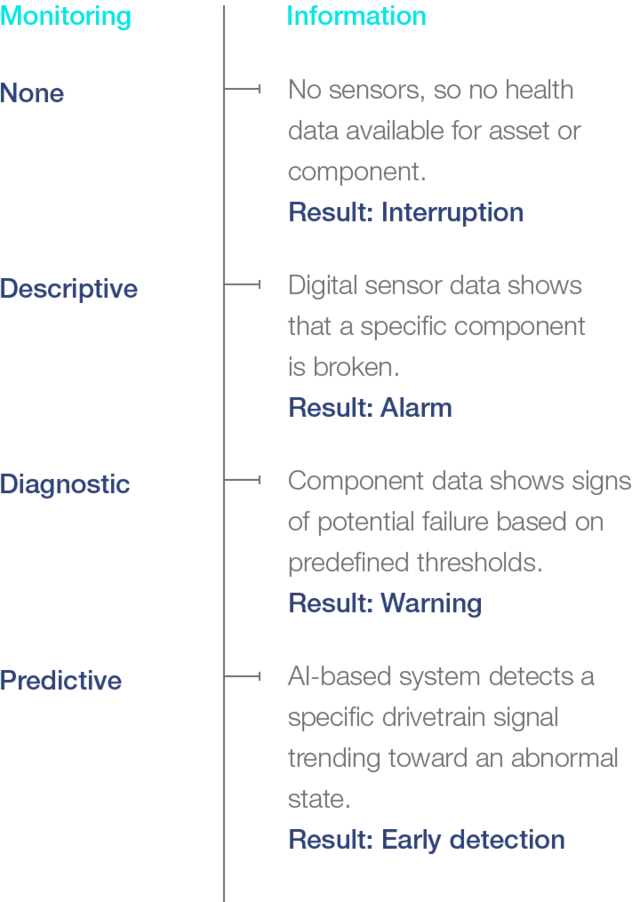

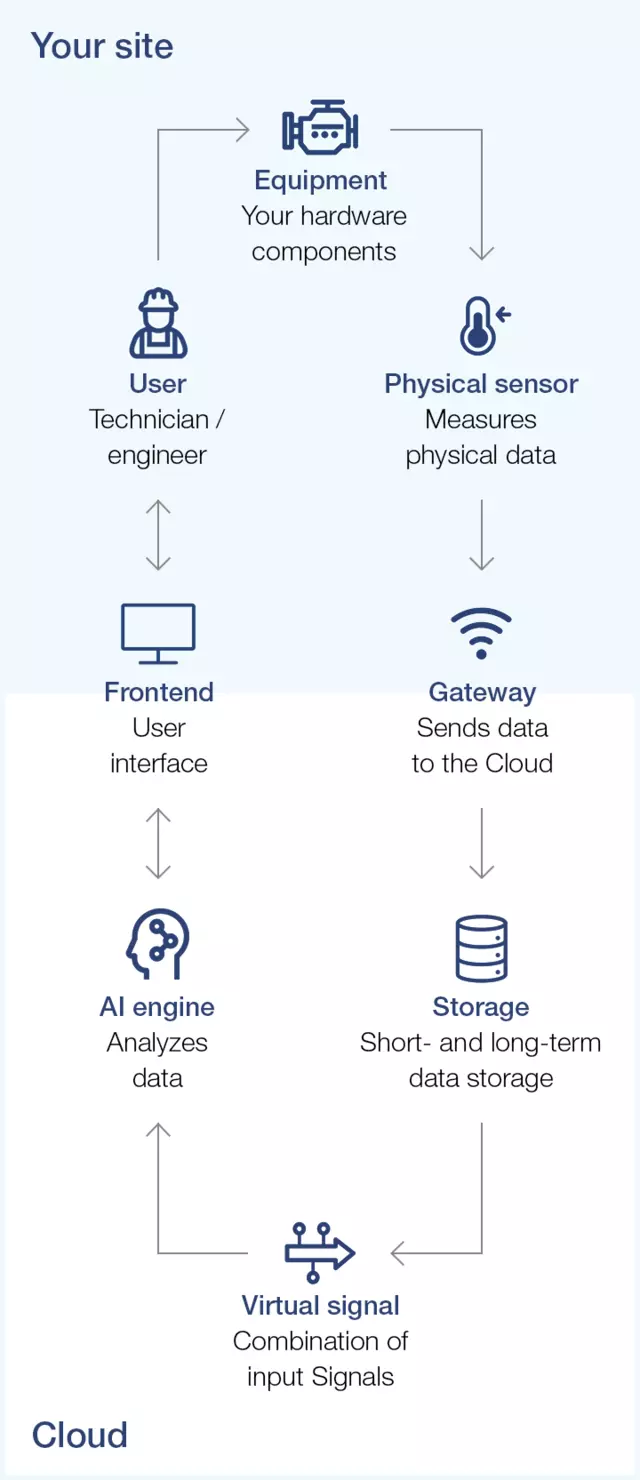

OnCare.InSight is a manufacturer-agnostic predictive maintenance system from Voith. Powered by advanced industrial AI, it offers insight into current equipment behavior and anticipates potential failures. All features and benefits are accessed via an intuitive frontend.

For perfect tailoring to your processes, Voith experts perform custom system setup based on an initial proof of value (PoV). Early detection with OnCare.InSight saves money on more extensive repairs that might otherwise be needed. It also reduces the opportunity cost of downtime by shifting maintenance to planned intervals.

Frontend functionalities

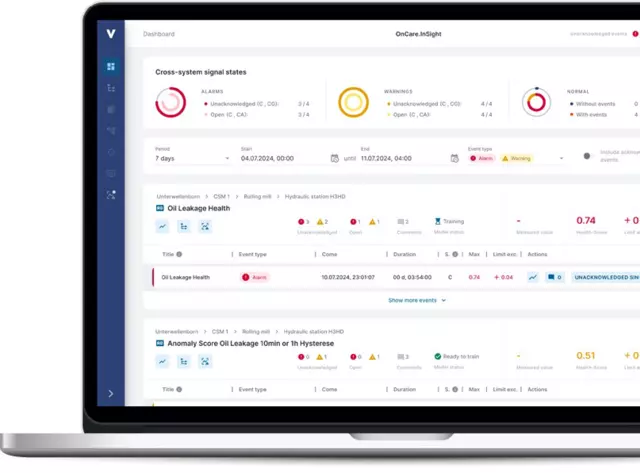

01 Event Dashboard

The event dashboard features an overview of all alarms and warnings for the connected asset. It provides a summary of the current state of all signals and of the events that still require acknowledgment. In addition, a list of previously acknowledged events can be sorted by type, timestamp, and other aspects.

02 Signal Details

Users can view how a particular signal is trending and examine historical data relating to this signal, such as alarms and warnings. Various input signals that impact a specific event are ranked by their respective relevance. The information in this section can be used for root cause analysis.

03 Event handling

Benefit from one-click bulk acknowledgment of multiple events, which can be labeled by type and component. It is also possible to input measurements for event resolution. Users can select whether a specific event constitutes an anomaly and whether the system should begin incremental training that incorporates this event. Retraining can be performed in the case of false positive or false negative events to enhance performance of the AI models.

04 Asset structure

View a process map of all monitored components and signals connected to OnCare.InSight, showcasing the asset hierarchy and relationships. Featuring details on unacknowledged events, alarms, and warnings, the asset structure differentiates between signal types. By highlighting signals with anomalous behavior, it also aids root cause analysis and enhances the efficiency of maintenance processes.

05 Model overview

The frontend provides an at-a-glance overview of all models, which can then be sorted or filtered by their type and status. Users can access a full history of all model versions, view the corresponding training queue, and reinstate a previous model version from the Model Versions page.

Industry applications in power, oil, and gas

Power

AI-based predictive maintenance in the power sector offers significant benefits by reducing downtime, optimizing performance, and extending equipment lifespan. Voith’s solution is applicable across various power plants, such as combined cycle power plants, nuclear power plants, and biomass power plants. Key use cases include monitoring oil pressure, temperature, and vibration to detect wear in actuators, converters, and bearings. Early detection of issues such as gear tooth damage and actuator failure enables timely intervention. By minimizing expensive repairs and operational disruptions, this enhances efficiency and reliability in power generation.

Oil and gas

In the oil and gas sector, the extraction, processing, and refining of petroleum and natural gas requires complex machinery and infrastructure. Voith’s AI-based predictive maintenance solution is ideal for applications on offshore rigs, FPSOs, onshore wells, refineries, and pipeline gas compression systems. Key monitoring use cases include tracking differential pressure, bearing temperature, and shaft vibration to detect issues like valve drive failure, compressor bearing coking, and seal damage. Early intervention prevents costly repairs and severe failures, ensuring continuous and safe operation.

Challenge: We conducted a proof of value using offline data to identify the root cause of increased gear vibration in a biomass power plant.

Added value from Voith: Gear vibrations were modeled as a target signal for operating states including summer, winter, steam extraction, and no steam extraction.

Challenge: Voith aimed to demonstrate the potential of its AI solution for early detection of issues such as increased coupling sleeve vibration.

Added value from Voith: Proactive maintenance with highly accurate AI models enables early anomaly detection to prevent downtime and damage.

Petrochemicals

Predictive maintenance powered by AI helps boost efficiency in petrochemical processes.

In the petrochemical industry, converting raw materials like natural gas and crude oil into valuable chemicals and products is essential. The efficiency and reliability of machinery are critical for preventing costly downtime and ensuring safe operations.

Our AI-based predictive maintenance solution offers early detection of potential failures, reducing downtime and enhancing safety. It is suitable for natural gas processing, agrochemical production, and petrochemical plants. Key monitoring use cases include detecting diaphragm coupling damage, turbo gear tooth or bearing damage, and overheating of compressor bearings.

Safety and performance in steel and mining

Steel

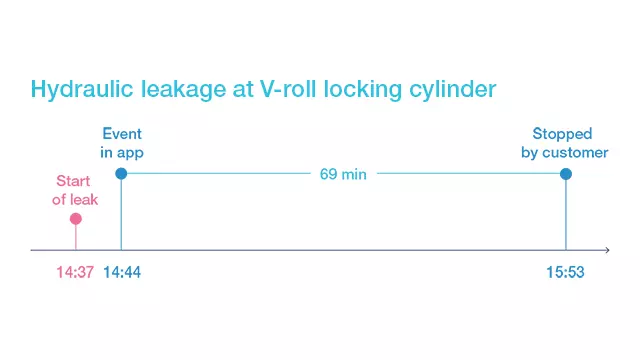

By enhancing equipment reliability and reducing unplanned downtime, AI-based predictive maintenance is critical for maintaining production efficiency in the steel industry. Our solution is applicable across various steel production processes including cold rolling mills, heavy profile mills, and hot strip mills. Key monitoring use cases include detecting oil leakage, hydraulic system health, correct roll changes, and vibration issues. By analyzing signals such as oil pressure, engine speed, and vibration, our system provides early warnings and helps schedule maintenance. It therefore minimizes disruptions and extends equipment life.

Mining

In the mining sector, the extraction, transportation, and processing of raw materials require highly reliable and efficient machinery to maintain productivity and safety. Predictive maintenance is critical for preventing unexpected equipment failures, which can cause significant downtime and financial losses. Our AI-based solution can be applied across the entire mining process, from extraction and crushing to material handling and processing. Key monitoring use cases include detecting drivetrain fractures, bearing damage, and material flow issues. By analyzing signals such as vibration, bearing temperature, and torque, our system provides early warnings, ensuring timely maintenance and minimizing operational disruptions.

Challenge: Oil leaks in the hydraulic system lead to sudden production interruptions and therefore unplanned downtime.

Added value from Voith: Avoiding unplanned downtime and extending production time serves to boost output.

Challenge: A customer operates two different semi-autogenous grinding mill configurations: one driven by a variable frequency drive (VFD) and another using a standard setup with coupling and gearbox.

Value proposition from Voith: Using offline data modeled after a real-world scenario, we aim to demonstrate the maximum achievable performance and how to completely prevent failures in the drivetrain.

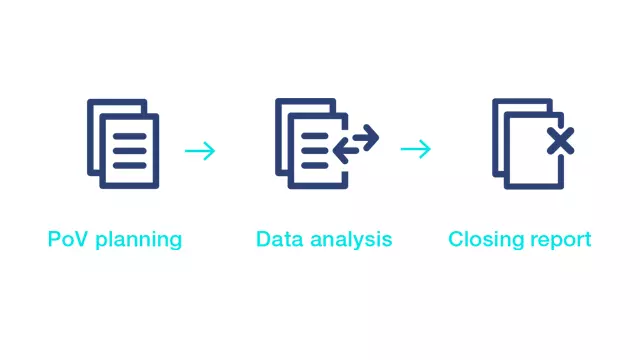

Added value at every stage

Planning begins with the joint definition of use cases, signals, and success criteria for the proof of value. Once these framework conditions are established, you supply the offline data to Voith for thorough investigation.

We then conduct an investigative analysis of the production data to prepare the data and AI model. This process includes detecting optimization parameters and culminates in a detailed result report, providing insights and recommendations for enhancing system performance.

In the online phase, deployment and training begin with the setup and testing of the cloud connection. The dataPARC suite is also configured and installed. This is followed by AI training, during which the historical data is prepared and the algorithm is trained and validated.

The setup also includes model visualization in the OnCare.InSight frontend. Continuous monitoring of selected parameters is provided through an annual subscription, which also includes an optional KPI evaluation phase.

Data security is paramount for industry 4.0. Voith’s AI-based predictive maintenance system meets the highest security and privacy standards, backed up by official certification. It maintains security processes at every step to ensure data integrity and confidentiality.

The advanced cloud infrastructure keeps users’ data safe, with encrypted data transfer and measures to block any unauthorized activity. Interfaces are robust, user-friendly, and feature access controls for continuous data security.

Contact our experts

Making AI work for you

Explore the potential of AI-powered systems – contact Voith today.

t +49 (0)8321 802-802