Special ShipsMore safety and efficiency for all types of special ships

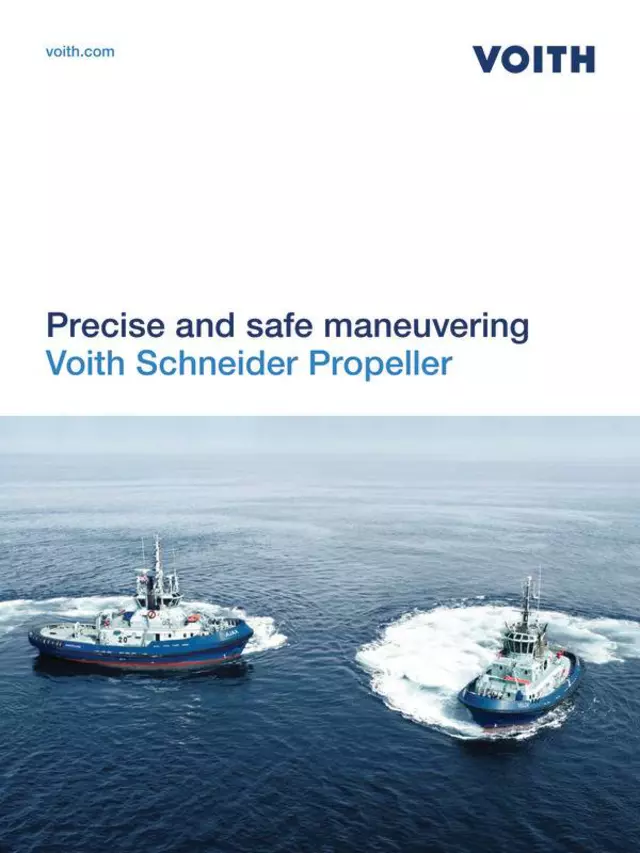

Whenever precise maneuvering in restricted areas such as harbors, rivers and even on the open sea is important, the Voith Schneider Propeller (VSP) demonstrates its superiority over conventional ship propulsion systems. This is even truer under adverse conditions with wind, waves or currents.

Long pushed convoys, buoy tenders or even floating cranes must have extremely good positioning response in limited sailing areas. Propulsion systems such as the Voith Schneider Propeller (VSP) and the Voith Inline Thruster (VIT) handle this job even under the most difficult ambient conditions.

Their fast and precise reactions to changing wind, wave and current conditions and when making course corrections provide the best possible handling characteristics and steering response. This not only provides more safety, it also increases the efficiency of the application.

The low noise level of the VIT raises the comfort of those on board. Extensive additional measures for sound insulation are unnecessary. The small amount of space required allows installation closer to the ends of the ship. This increases the effective leverage, allowing power to be reduced with respect to conventional transverse thrusters.