2019-05-06 CLDP servo drives - maximum flexibility and high energy efficiency for test benches

- Self-contained, compact and highly reliable linear drive

- High power density and dynamics

- Low energy consumption and TCO

Structural strength test bench from IABG for complete automobile chassis systems. (Image copyright: IABG).

Heidenheim, Germany. Characteristic of Voith's self-contained CLDP servo drive are its wide range of applications and high energy efficiency. This is why the test specialists from IABG exploit the advantages of the drive when developing systems for testing springs or stabilizers.

Because of its wide range of uses, the self contained servo drive CLDP (Closed Loop Differential Pump) drive has already proven effective in very diverse areas of application. Recently, for example, IABG analysis and simulation specialists have been making good use of the properties of linear drives in VTRCs (Variable Test Rigs for Resilient Components), which can test the function and service life of springs and stabilizers, including all associated components like spring pads, bearings or coupling rods for car stabilizer.

The free-programmable Voith drives enable maximum flexibility in the testing process, because the servo drive CLDP drive offers all the advantages of the electrical and hydraulic environment in one self-contained drive.

Compressive and tensile forces are required to the same extent. Highly dynamic chassis movements, of the kind typical in cars, can be replicated exactly. However, for components made of rubber and plastic, it would be inappropriate to focus only on highly dynamic movements. This is not an issue for the CLDP drives, because they can also realize slow movements under difficult climatic and environmental conditions. The test benches already built can produce strokes of up to 600 mm and forces of plus and

minus 40 kN.

The development of the test benches is the outcome of close collaboration between IABG and Voith, who jointly defined all interfaces for the integration. Voith is supplying the complete drive package including servo inverter and electrical interface card and can also commission the system and provide accompanying training. In the process Voith will also be responsible for the calculation and dimensioning of all hydraulic and electrical components.

In these and comparable applications, the Voith drives offer a crucial advantage – their enormous energy efficiency. The high efficiency allows an up to 70 percent reduction in energy consumption compared with conventional hydraulic drives with proportional valves. When used with springloaded test components, e.g. in the IABG test benches, the regenerative principle of the drives also feeds tension potential energy back to the system. This energy is then available for simultaneous asynchronous movements of other drives. Conventional hydraulic systems convert this energy into heat. Thanks to the option of running a second system asynchronously, the CLDP helps to substantially reduce overall running costs (TCO). In addition, the high degree of flexibility means that very different components can be tested in one system, which optimizes system capacity and increases productivity. The largely wear-free drive is also the basis for the high availability of the entire system. For example, in some cases, the IABG test benches run for several weeks in continuous unmanned operation – seven days a week, 24 hours a day.

Another benefit is that thanks to the compact design, the CLPD servo drive and associated actuators are located precisely above the component testers. As a result, the system needs much less installation space than comparable products. This also reduces the need to install and maintain piping. Because the CLDP servo drives, as the sole interface, need just one power feed, the systems are independent of the remaining infrastructure of a plant. In action, the CLDP servo drive basically works like an electromechanical drive, except that its power density and maximum achievable forces are much higher.

IABG builds these test benches for car manufacturers and their subsuppliers. But as a service provider, the company also conducts these kinds of tests itself. Its customers include the world's leading spring manufacturer NHK, and renowned car manufacturers like Audi or Hyundai.

“Operators of an IABG system with Voith CLDP drives gain a lot of advantages,” says Sebastian Hoffmann, the respective head of department at IABG. As well as the significant electricity savings, the linear drives also enable the use of resources to be reduced, as they work with a much lower volume of oil. “Above all, however, they substantially extend the range of tests on offer and increase productivity.”

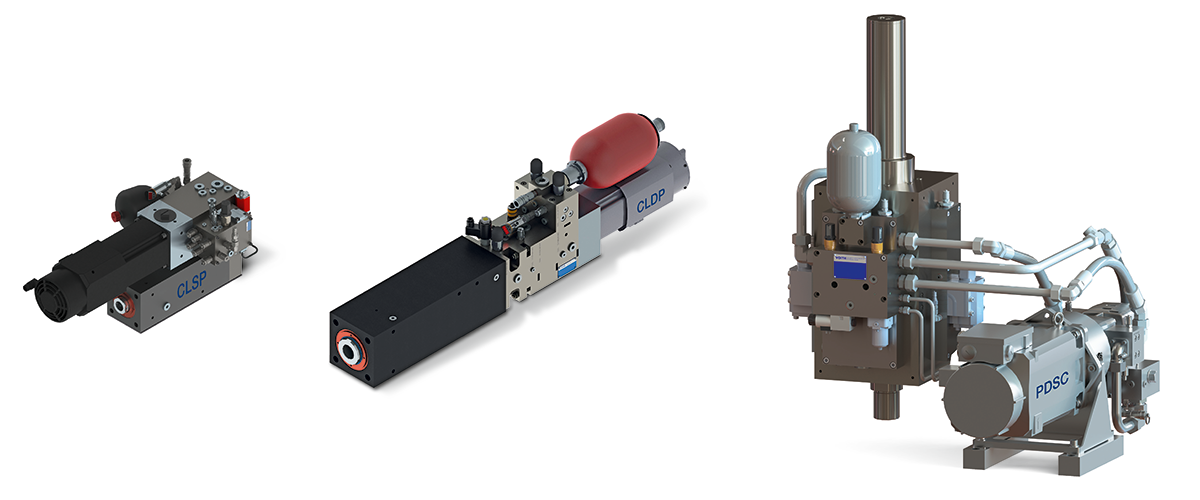

Alongside the CLDP, the Voith range of self-contained servo-hydraulic linear drives also includes the smaller CLSP, featuring load-dependent changeover of the hydraulic transmission, and the highly efficient PDSC press drive. The systems have already proven efficient in cutting, bending and forming machines with position and/or force control. In addition, the drives offer an advantageous alternative to spindle drives with servo motor.

About the company

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

More about the Voith Group

The Group Division Voith Turbo is part of the Voith Group and a specialist for intelligent drive technology, systems as well as tailor-made services. With its innovative and smart products, Voith offers highest efficiency and reliability. Customers from highly diverse industries such as oil and gas, energy, mining and mechanical engineering, ship technology, rail and commercial vehicles rely on the advanced technologies and digital applications of Voith.