In the case of maritime applications, this expertise is deployed, for example, in the electrification of the propulsion system of ships. The best example of this is the electric Voith Schneider Propeller (eVSP): Thanks to its powerful, directly integrated permanent magnet electric motor from ELIN Motoren, a subsidiary of Voith Turbo, it delivers high torque and a fast response time. Without any gears whatsoever.

The result is a reliable, energy efficient, environmentally friendly and compact drive unit that is ideal for offshore and ferry applications and for use in tugs.

For example, our existing product range is already facilitating a secure data connection within the scope of the digitalization of rail freight transport. Digital automatic couplings like the CargoFlex open up entirely new possibilities that make rail freight much faster, safer and more efficient and help reduce emissions in accordance with the European Green Deal.

The result: safer transport and resource-conserving vehicle operation as well as a much faster and more extensive availability of goods all over the world.

Exceptional electrical system solutions like the Voith Electrical Drive System (VEDS) for commercial vehicles are already making a sustainable contribution to urbanization and the decarbonization of public transport in cities. Moreover, advances in storage technologies are increasingly making the vision of emission-free long-distance and freight transportation a reality.

What’s more: In the UK alone, there are now well over 1,000 electric buses on the roads that are powered by our VEDS. It offers an officially confirmed best-in-class efficiency advantage over competitor vehicles with a comparable battery size. And the numbers are set to increase.

As a technology partner and driver of innovation, we are making a sustainable contribution to the transformation of industry – and through the electrification of our products ensure their competitiveness into the future. For example, with this in mind we have developed the electric drive system E-Pack together with ELIN Motoren, a subsidiary of Voith Turbo. This gives our customers a highly efficient package solution from a single source.

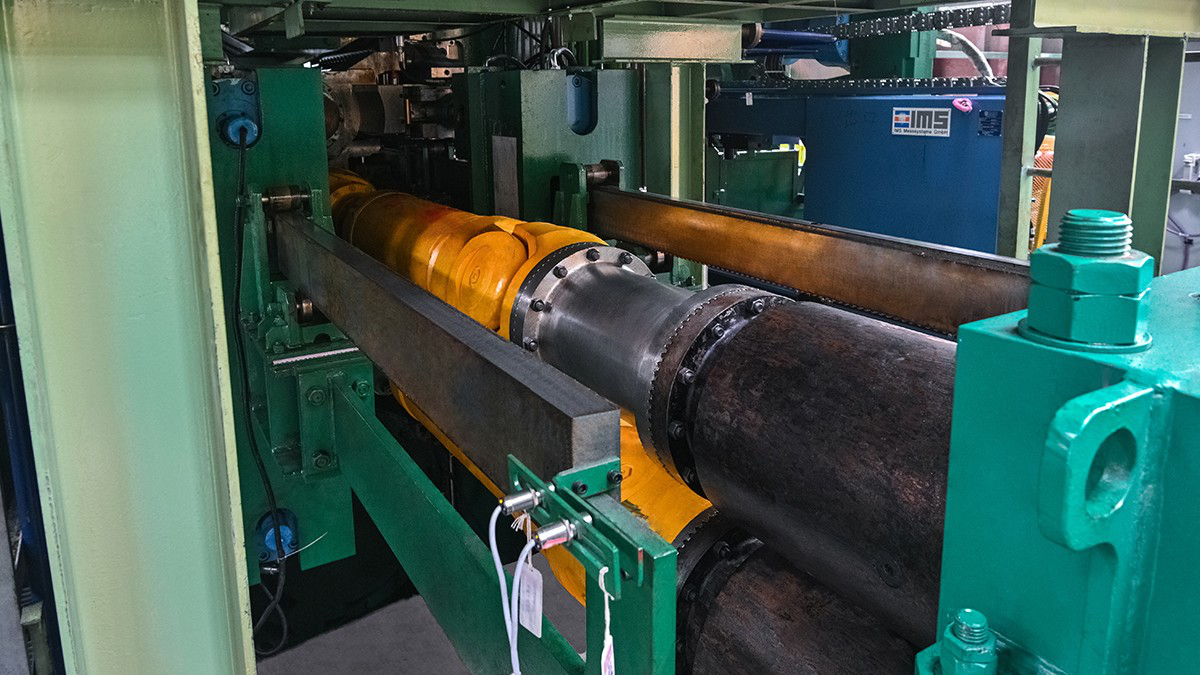

The combination of electric motor or generator and gear unit is characterized by its robust construction and compact design. Compared to conventional designs with parallel shaft gear unit and separate connection couplings, the E-Pack reduces the required installation space by approx. 30% in length and 10% in width. This is an important aspect for systems where space is at a premium, e.g. in the offshore segment.

We exploit the potential of digitalization in a targeted manner and combine it with our profound understanding of the various requirements of our customers. The best example of this would be the digital monitoring and maintenance tools from our OnCare family.

With OnCare.Health UJS we are offering an intelligent, modular torque measuring system for the condition monitoring of universal joint shafts and complete drivetrains. The self-learning data diagnostic system OnCare.Health Vorecon monitors and analyzes machines in real time. And OnCare.InSight, our new AI-powered system for predictive maintenance, predicts potential failures before they occur.

In this conjunction, our drive and control systems have proven effective for decades. With our innovative technologies we ensure continuity in change and enable the safe transport of the most important energy sources – from the most remote extraction sites to the transshipment centers of the global economy and into modern megacities.

To this day, a prime example of maximum reliability at lowest TCO is the Vorecon – our legendary, fully mechanical, variable speed planetary gear unit. It is the perfect combination of hydrodynamic power transmission and precise speed regulation and is therefore ideally suited for pump and compressor operation. Not to mention its superlative average service life of several decades.