Digitalization is transforming industry in an unprecedented way

By “Industry 4.0” and “Industry 5.0”, we mean an interconnected and data-driven sustainable production, the Industrial Internet of Things (IIoT) and the outcome-oriented and assisting use of industrial artificial intelligence (AI). Following the mechanization through water and steam power, the use of electrification and conveyor belts to facilitate mass production and the introduction of electronics and IT, we are now pioneering the next industrial revolutions and the age of AI.

It will fundamentally change how we live and work, manufacture goods, travel in our world and how we sustainably shape and maintain planet Earth. Voith is a globally active technology company with a long and successful history, specializing in various markets: For more than 155 years we have been developing sustainable technologies for future generations. We will continue to do so, aided in no small part by the achievements of Digitalization. Digitalization in industry encompasses all stages of the value chain – from development, through production, to brand-new business lifecycle models. Find out about our range of digital products!

Papermaking 4.0

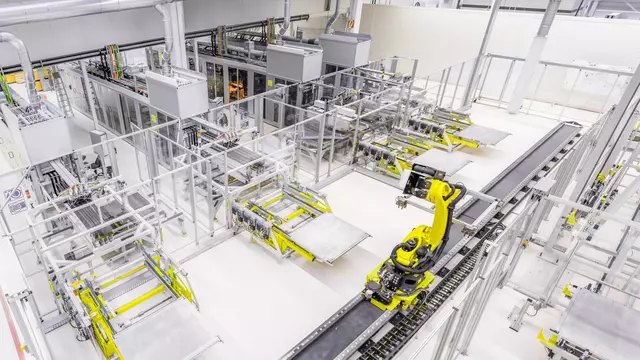

Paper manufacturing is a costly process. Due to the growing price pressure, manufacturers are constantly faced with new challenges to remain competitive. This requires increasingly complex systems to maximize efficiency along the entire value chain – usually across several production sites. Voith meets these requirements with digital technologies that optimize the production process and significantly reduce maintenance costs and downtimes.

As a technology leader and pioneer in the paper industry, Voith supplies technologies, products and services for the entire paper production process from a single source – from packaging, tissue and board to graphic and specialty papers.

For us, the digitalization of paper production means identifying innovative manufacturing methods across the entire value chain by making data-based decisions and thus achieving higher productivity and profitability.

With Voith as a full-line supplier, our customers benefit from a broad service portfolio for all sections of the paper manufacturing process. To further push the envelope, we have invented intelligent paper production – Papermaking 4.0. For this, we are leveraging most modern technologies along our hybrid technology stack with dataPARC.cloud within all our digital solutions, thus providing the ideal basis for predictive maintenance, digital assistants & tools for paper production and tailored data-driven business models.

As an innovation leader, Voith equips you for intelligent and sustainable paper production – not to mention OnEfficiency and OnCare. We work jointly with you to develop individual product and service solutions that are precisely tailored to the challenges of tomorrows market.

Digital opportunities – get started now!

With our experience of more than 155 years of industrial history, we are technology leaders in the hydropower, paper and drive solution markets. We also use our domain knowledge to implement digital transformation, both for ourselves and our customers.

Voith helped shape the first industrial revolutions and will make a crucial impact on the fourth. Digitalization helps protect precious resources. Intelligent systems and services based on data platforms like our dataPARC cloud information hub secure the future and competitiveness of our customers.

At Voith, we see the great challenges of the present and the future as opportunities. We provide solutions for the automation and digitalization of hydropower, papermaking and mobility, as they will play a crucial role in digital transformation.