2021-04-16 With the new ProTect NG from Voith, important press felt measurements can be carried out safely and even more comfortably

- Press felt measurements are highly relevant for the operation of a paper machine. However, the safety and health of the employees must not be subordinated for the measurement.

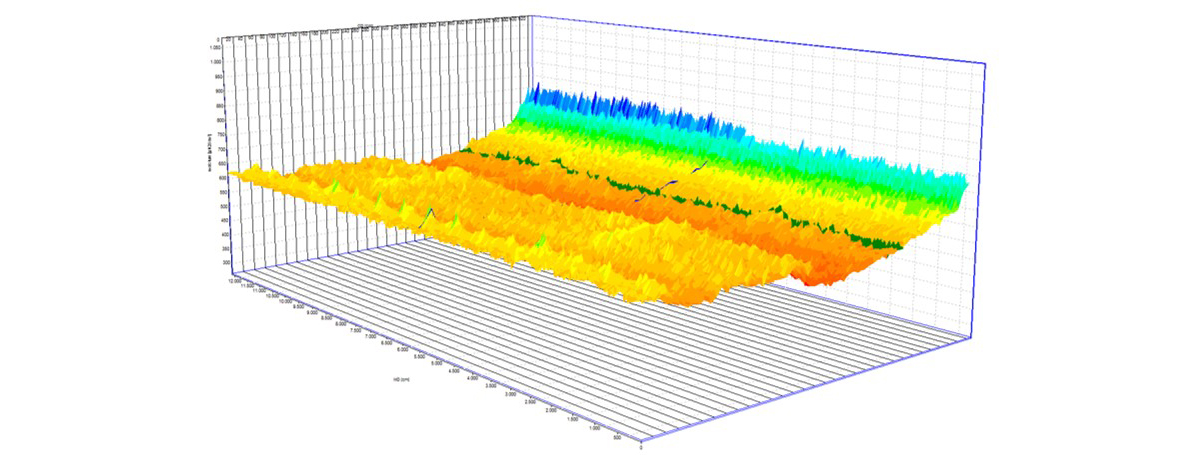

- With the help of the self-driving ProTect NG, important criteria of press felt performance - such as water content, water absorption capacity and felt tension - are measured and shown in a 3D diagnosis.

- The measurements can be used for fault diagnosis, prediction of remaining running time and optimization of the felt design.

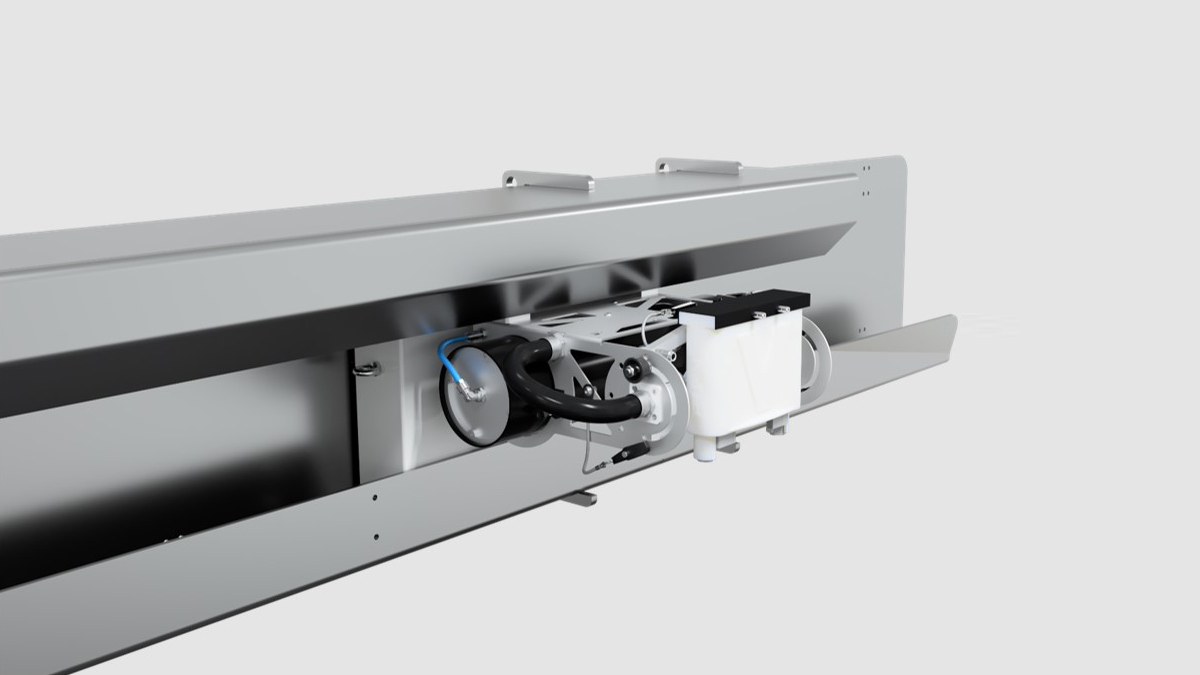

Low effort: ProTect is a carriage and rail system that picks up the felt measuring device brought along and moves it across the machine. Supply and data lines are redundant.

HEIDENHEIM, GERMANY. When measuring press felts manually, there is often a risk of jamming, tripping and slipping. At some positions, the employee is additionally exposed to enormous heat and the constant danger of a felt break also represents a significant, permanent safety risk. Yet, the measurement of felts is an important component in the papermaking process. The automated measurement with Voith´s ProTect NG (Next Generation) therefore offers an excellent alternative to determine the important felt data without risk.

The ProTect system consists of an autonomous carriage and one or more fixed rails (traverses). The user waits on the runway during the measurement and thus no longer remains in the hazardous area. A carriage can be used in different paper machines. It does not matter how wide the machines are, and whether the carriage has to run to the left or to the right.

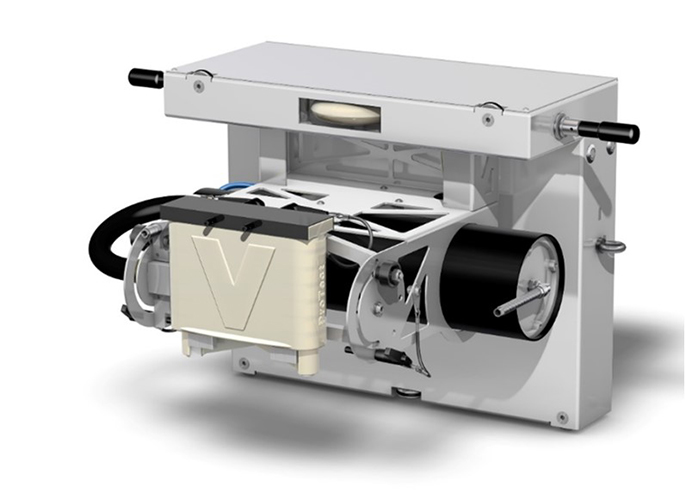

The new generation of the ProTect NG carriage also offers programmable measuring cycles, self-diagnosis and remote service access. Furthermore, the carriage speed can be reduced to the point where 3D mapping travel is possible. The traverses can be installed in almost any position, even those that are difficult to access. No water, electricity or compressed air connection is required at the actual measuring points, as the ProTect NG carriage is a "self-supplier". Only the charging station needs a 110/220V power connection - and in the best case a water connection to fill the tank.

Optimized diagnostic options with the new ProTect NG

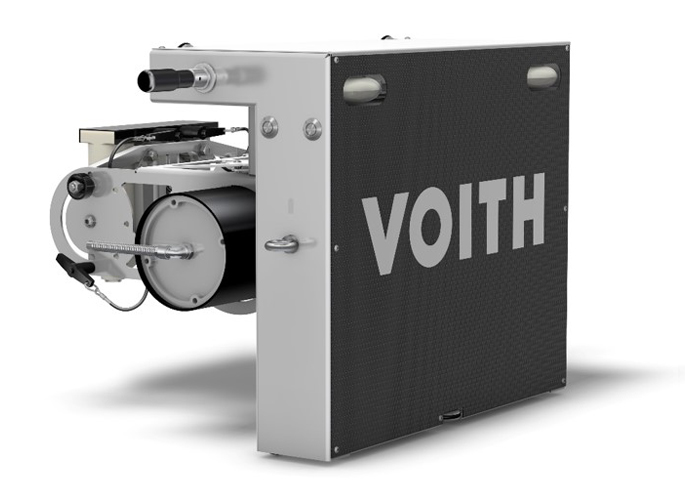

The new ProTect NG continues the global success of ProTect and offers several new benefits for customers. "With the experience of much more than 200 installed positions, ProTect has become the standard for semi-automatic press felt measurements. ProTect NG is the consistent further development of the original ProTect system with improvements in all areas. In addition to weight reduction and optimized serviceability, functionality has been improved above all," explains Torben Beckmann, Global Product Manager at Voith Paper.

ProTect NG provides an optimized diagnostic option, which can be combined with all available measuring instruments. The integrated display shows the most important carriage parameters as well as the pre-installed measuring run programs. The intuitive operability provides even inexperienced operators with quick access to the various analysis options. ProTect NG also convinces with its further reduced weight, which is achieved by using carbon and 3D-printed parts. The lower weight is important for more comfortable handling combined with increased safety for the staff.

3D diagnosis of the press felts in CMD

In combination with suitable felt measuring devices, the very low speed of the ProTect NG enables three-dimensional scanning of felt surface temperatures, moisture and water permeability profiles of the press felts. Depending on the machine width, a 3D scan can take several minutes, during which time the service technician now no longer needs to be in the dangerous area. Voith offers a tensiometer specially developed for felt tension measurements that saves the values on a USB stick during the measurement. After the measurement, the measured values are read out in the PC.

About the company

The Voith Group is a global technology company. With its wide range of plants, products, services and digital applications, Voith sets standards in the markets for energy, oil and gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 20,000 employees and earns 4.2 billion euros in sales. It has locations in over 60 countries and is one of Europe’s larger family-owned companies.

read more

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and supports customers in significantly reducing their carbon footprint. With its comprehensive automation products and leading digitization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art, digital technologies to increase the availability and efficiency of their systems in all areas of the production process.