A challenging passage through the Suez Canal

The iconic Suez Canal is a crucial maritime link between Africa and Asia. Massive tankers and container ships pass through its waters daily. Accompanied by the skillful crew on board the Voith Water Tractors (VWT), their safe and efficient passage is ensured.

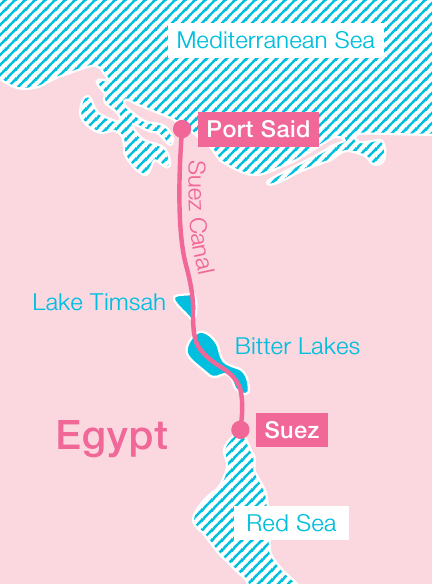

Officially opened in 1869, the Suez Canal permanently altered the international shipping industry. By cutting out a treacherous 7,000-km trip around the southern tip of Africa, this channel created the shortest maritime link between the Mediterranean Sea and the Red Sea, and the Eastern and Western Worlds.

A more recent expansion, completed in August 2015, saw the widening and deepening of the canal, as well as the addition of the New Suez Canal, a 35-km canal running parallel to the original. Larger ships can now travel in two-directional traffic, and the transit time is expected to drop from around 18 hours to 11. The upgrade will double the canal’s daily average capacity to 97 vessels by 2023. Since the inauguration of the original, the ships passing through the canal have increased significantly in numbers, but also considerably in size.

Cargo colossus

For safety reasons, only Suezmax ships up to a beam of 77.5 m are permitted to pass through the 205-m-wide canal. This still means that giant cargo container ships, including the imposing Maersk Triple-E Vessel, which can carry 18,000 containers on board, can travel through.

Such vessels are unwieldy beasts, and therefore need expert guidance through the narrow waterway and shallow depths to ensure a safe transit. To this end, the Suez Canal Authority (SCA) operates 19 VWTs, and has recently placed an order for four more.

Entirely dwarfed by the oversized ships, these smaller, sophisticated vessels can nonetheless hold their own up against the colossal vessels. In their element, the tugs become the giants.

“Three or more tractors drive stand-by with the large vessels as they travel through the canal, ready to intervene if there are any issues,” explains Ralf Rocholl, Sales & Application Manager at Division Turbo. “If they have an engine failure or rudder failure, a VWT is on hand immediately to help prevent a major incident or accident.” They need to be able to react rapidly in the event of a fire, for instance. A combination of agility, precision and efficiency is the key to their appeal.

The precise maneuverability is guaranteed by the Voith Schneider Propeller – two are fitted in each VWT – which combines propulsion and steering in one robust unit. Easy handling makes the crew’s dangerous task much easier and safer. The man-machine interface is particularly user-friendly, so it doesn’t take long for the crew to adapt to the vessel.

Dwarf vs. Giant

Dwarf

Mosaheb 4

- Length: 36 m

- Beam: 12.5 m

- Power: 5,280 kW

- Speed: 13 knots

- Bollard pull: 70 tonnes

Giant

MSC Maya

- Length: 395 m

- Beam: 59 m

- Power: 62,500 kW

- Speed: 22.8 knots

- Capacity: 19,224 TEU

Training tailored to Suez

To ensure that the crew has mastered the maneuvers and can execute them with absolute confidence, Voith provides a tailored, enhanced training program for the crew members and pilots from the SCA.

The training covers theory, plus maneuvers in the safe environment of the computer simulator at the Voith headquarters in Heidenheim, and also out at sea in northern Germany. A one-week intensive program on board the crew’s actual tug concludes the training.

For the port authorities, the program is viewed as an opportunity to increase the knowledge and skilled capabilities of the local crew. This translates into higher safety for the canal. Several tug crews and pilots participate in training, which also seeks to strengthen the interaction and collaboration between the pilots and the crews on the Suez Canal.

“Our training is quite unique in the industry, but it is often an integral part of our service for our customers. One that they value. It’s how we help them to ensure the absolute safety and efficiency of their operations,” explains Rocholl.