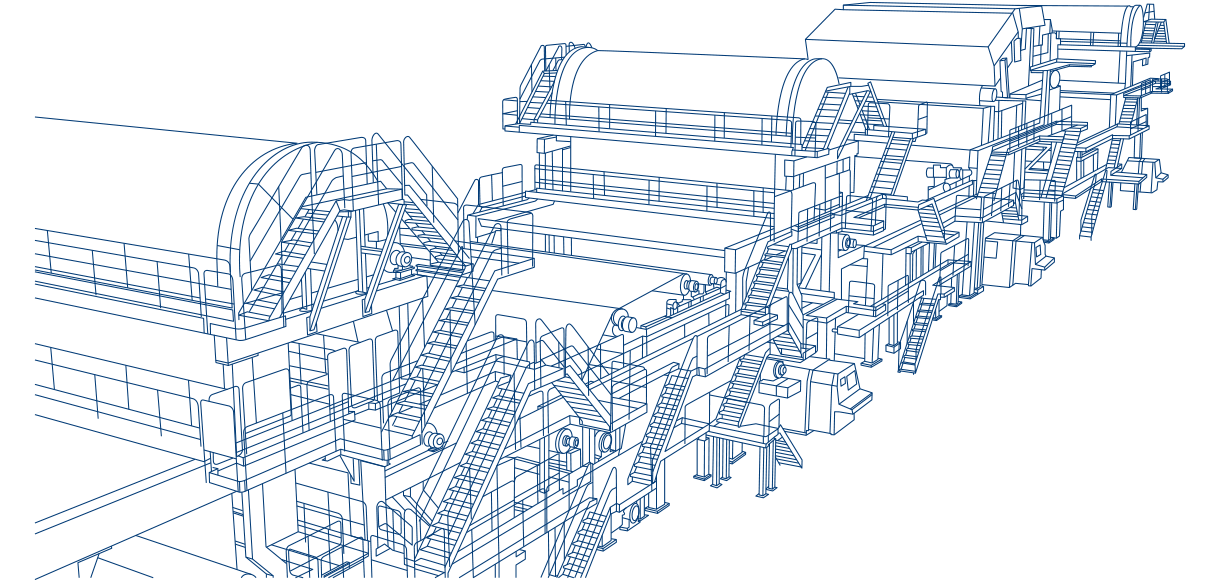

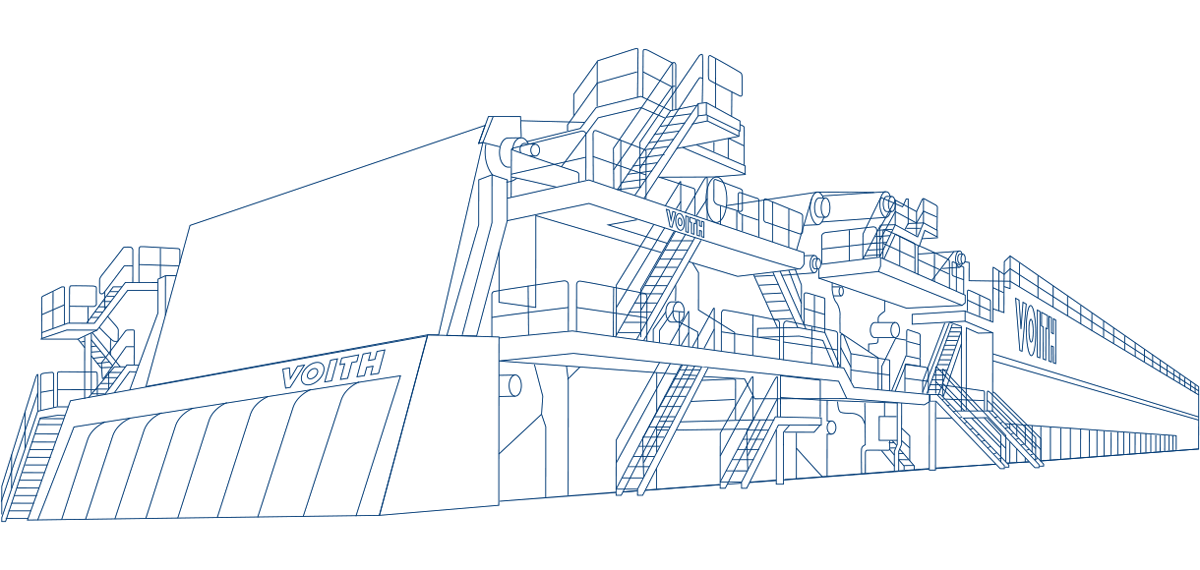

All from one single source

Our global team fights for the success of papermakers, delivering robust solutions to meet our customers’ needs – all from a single, reliable source. Based on our expertise and experience, we optimize along the entire machine life cycle. Digitally enabled combinations of our unique product and services portfolio set the benchmark in the industry. Innovations and breakthrough technologies ensure maximum efficiency and sustainability of our customers’ papermaking process.

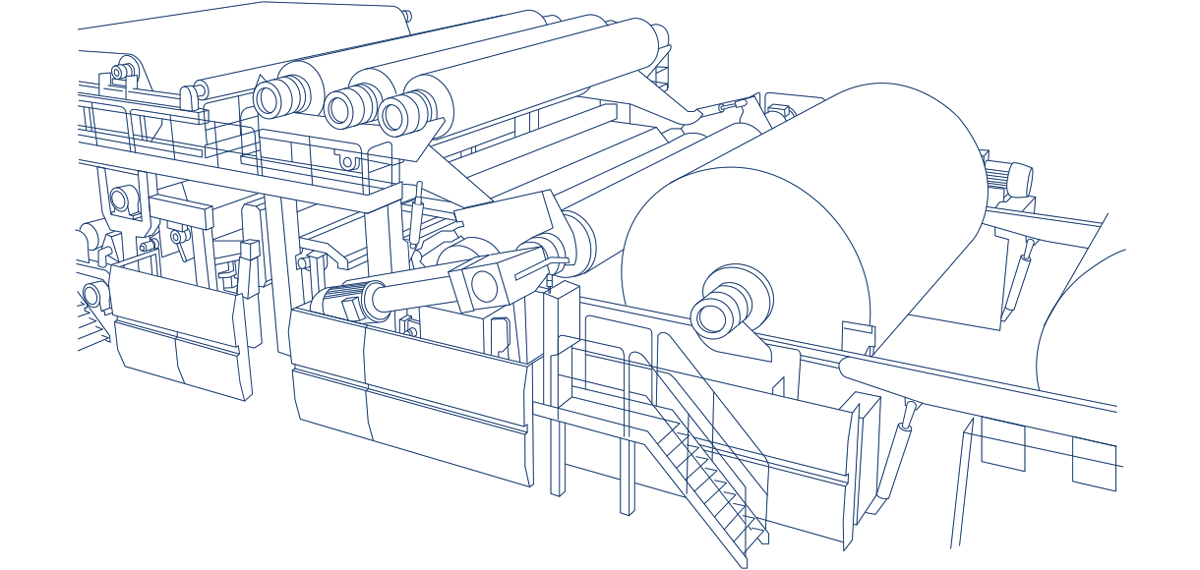

Discover our broad portfolio of products and services

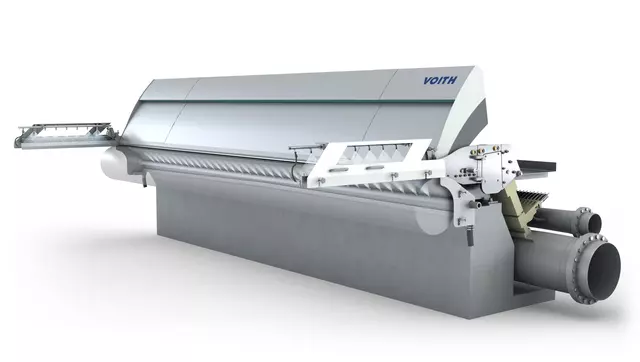

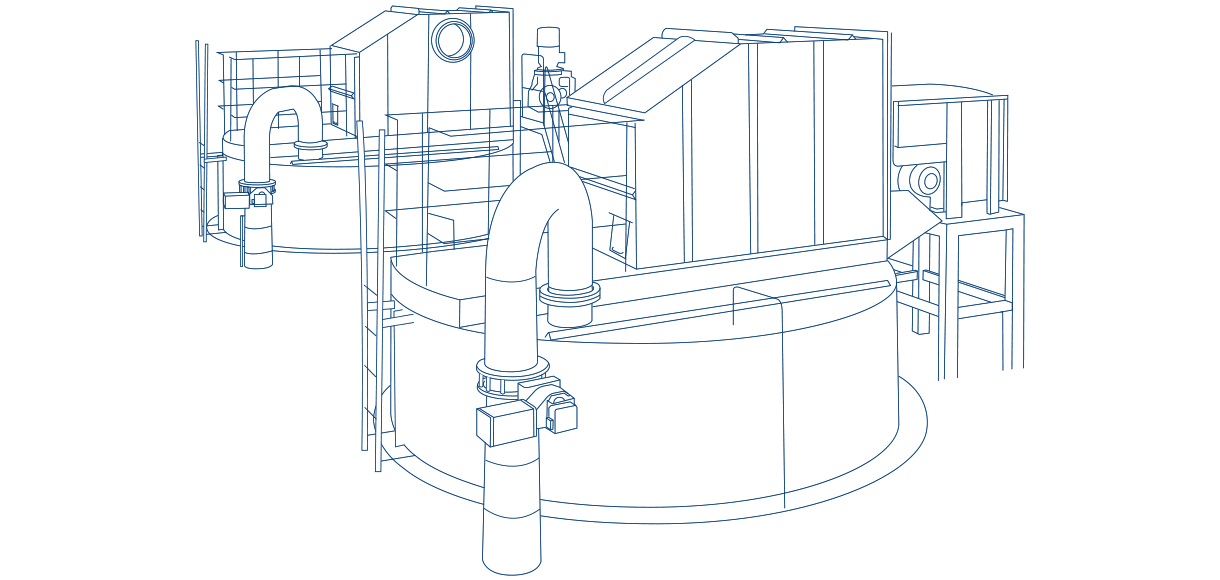

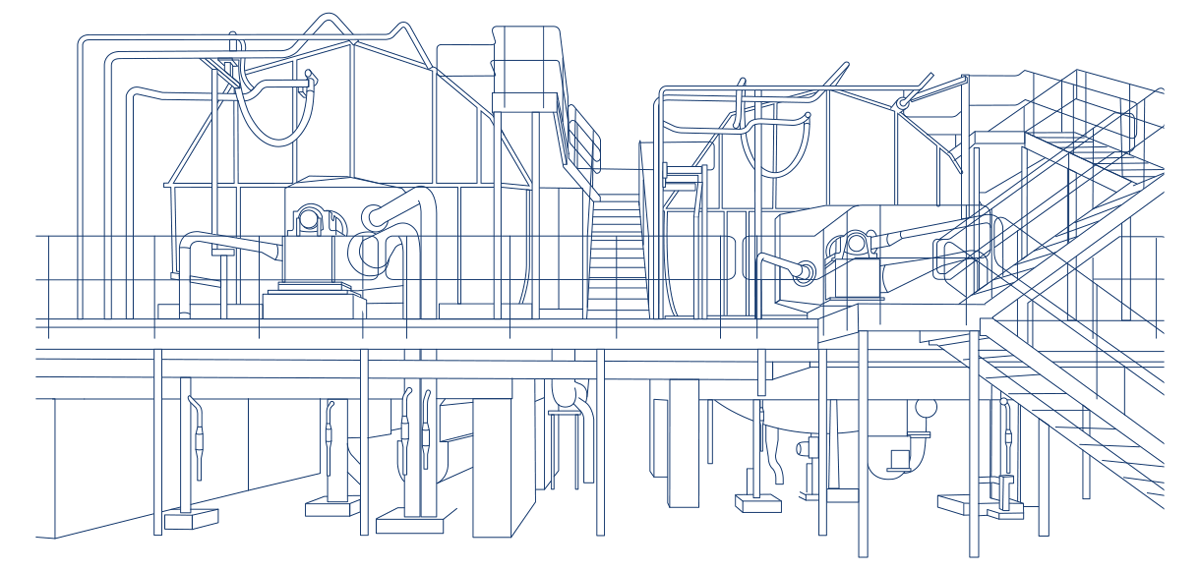

Stock Preparation

With the innovative stock preparation products of the BlueLine family, customers profit from proven Voith quality and at the same time lower costs for energy, fiber, water and maintenance as well as enhanced runability and safety.

Visit the product page

Voith’s extensive product and process know-how in the field of OCC is unique in the industry. It allows paper manufacturers to optimize their entire recovered paper stock preparation by maximizing both efficiency and quality.

Visit the product page

For the manufacture of products based on virgin fibers, Voith offers its customers integrated solutions for an efficient and sustainable paper manufacturing process. Experienced experts design customized systems for a wide range of requirements and paper grades, from tissue to specialty papers, board and packaging.

Visit the product page

Achieving sustainable reduction of fresh water consumption is one of the key challenges in the development and operation of production facilities. With Voith's professional AquaLine water management solutions, significant water savings are realized leading to more sustainable paper production.

Visit the product page

Raw Material Handling

Pulping

Cleaning

Screening and fractionation

Flotation

Refining and deflaking

Compact Dispersion System

Sustainable Solutions

Discover our solutions for sustainable and cost-efficient production

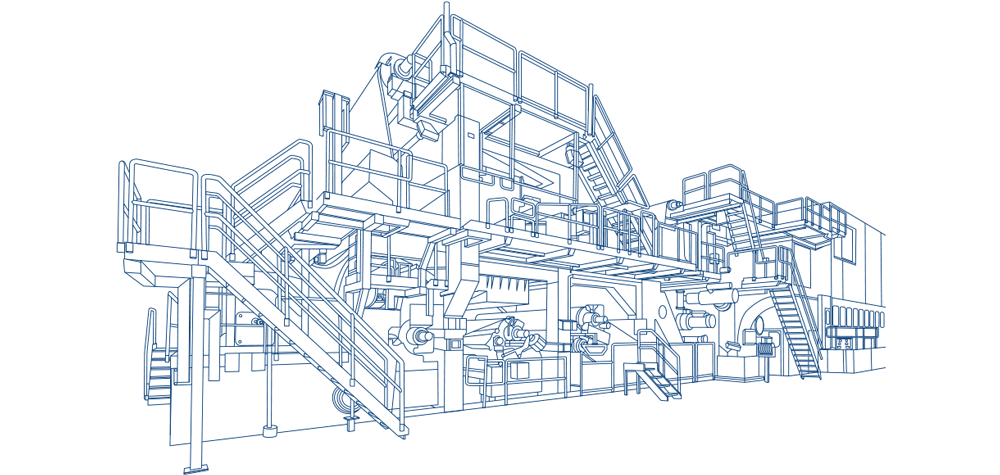

TissueForm ITY

TissueForm ITY

By implementing our ITY with optimized support points in the paper side we were able to reduce the amount of expensive long fibers in the receipt.

TissueFlex XD

TissueFlex XD

- By replacing the competition felt with TissueFlex XD we were able to reduce the gas and electrical energy consumption of the hoods and achieve better moisture profiles.

- By replacing the competition felt with TissueFlex XD we were able to increase the dryness after press by 1%, resulting in ~ 4% drying energy consumption.

MatchSoft

MatchSoft

By replacing SPR blind drilled rubber cover from competition for MatchSoft with blind drilled cover design we increased the open area and improved surface design stability, resulting in energy savings and production increase.

Evolution

Evolution

By replacing the competition felt with our Evolution felt we were able to reduce energy consumption by 9%, increasing the dryness after press.

+Peak

+Peak

The +Peak technology is a specially developed elastomer material. Used in press fabric, it reduces the start-up period while maintaining steady-state performance throughout its operational life. This unique Voith product is a perfect solution for increasing dewatering performance in the press section of your paper machine.

OnEfficiency.DIP

OnEfficiency.DIP

OnEfficiency.DIP optimizes an existing DIP line to create constant DIP quality at minimum cost. The existing flotation is supplemented by additional actuators; new sensors are installed to monitor the quality parameters.

The DIP quality fluctuations created by incoming raw materials or production changes are reduced by dynamic adjustment of the losses at the washing/flotation as well as real-time optimization of the bleaching chemicals dosage.

AquaLine Zero

AquaLine Zero

With Voith's AquaLine Zero water management concept, significant water savings are realized due to closure of the water circuits. CO2 emissions can be reduced by about 10% at the same time.

FlowJec

FlowJec

With FlowJec, Voith has developed today’s most efficient dosing system for sustainable and resource-conserving dosing of all chemicals and additives in the paper manufacturing process.

CleanLine Extract 4D

CleanLine Extract 4D

CleanLine Extract4D, with water jets in four directions, overcomes the limitations of conventional cleaning systems.

SolarPress

SolarPress

In the press section, SolarPress roll covers ensure optimum dewatering.

VForm

VForm

VForm hydrofoils allow individual adjustment of foil angle or height for each grade and basis weight. Thus, paper manufacturers benefit from maximum flexibility and an extended operating window.

HydroSeal

HydroSeal

With HydroSeal the integrated lubrication of the sealing strips requires less water and energy to operate. That leads to a reduction in the consumption of fresh and waste water, as well as energy consumption.

HelioX

HelioX

As the first of its kind, the emitter structure of HelioX is manufactured by advanced 3D print technology, achieving unmatched values for efficiency, combustion quality, lifetime and safety.

DuoDry CC

DuoDry CC

DuoDry CC is setting new benchmarks for an effective and reliable curl correction. It is the first vertically inverted dryer group, and papermakers benefit from enhanced runability combined with attractive cost and energy savings potential.

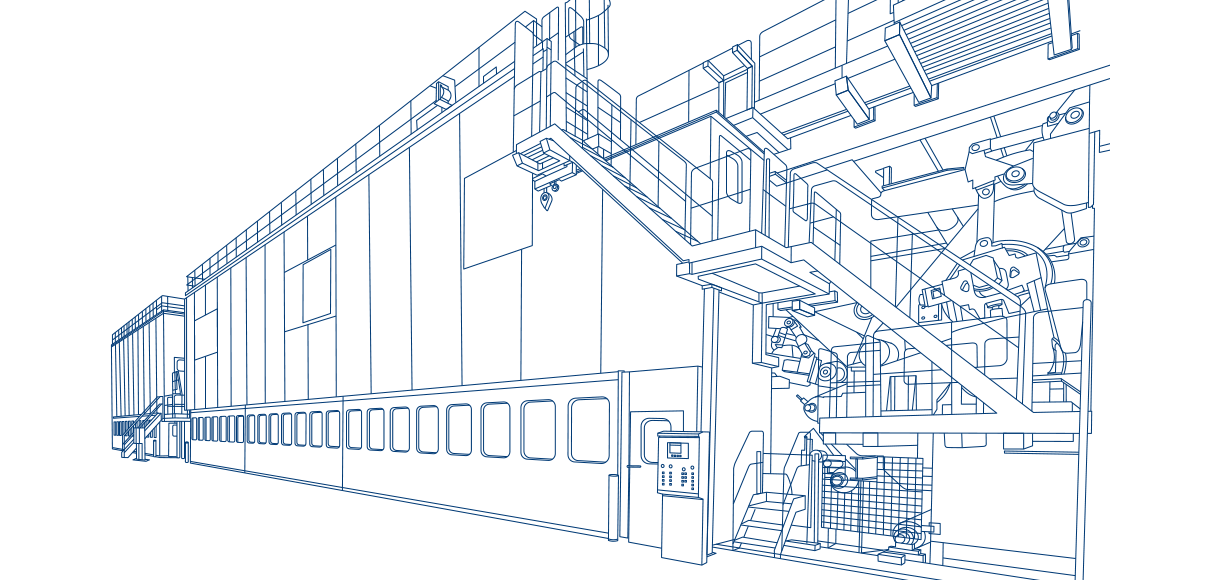

EcoHood 65

EcoHood 65

EcoHood 65 provides an operating dew point of up to 65°C for the highest energy efficiency. The amount of supply air and exhaust air can be reduced by almost an additional 20% compared to EcoHood 62.

xSteam Pro

xSteam Pro

xSteam Pro saves both steam and cooling water compared to other systems, resulting in significant energy savings and lower operating costs.

CleanLine Excell

CleanLine Excell

Voith’s CleanLine Excell is an efficient cleaning system for consistent and uniform cleaning of the surface and structure of forming and press fabrics.

EdgeExpert

EdgeExpert

The unique edge trim concept EdgeExpert defines the web edge in the stock jet as it exits from the headbox, resulting in fiber savings and increased edge stability.

DuoShake DG

DuoShake DG

The DuoShake Digital Generation shaking unit for the breast roll contributes to a more homogeneous distribution of fibers and an increased orientation of the fibers in cross direction.

qDry Pro

qDry Pro

qDry Pro is a space- and energy-saving drying concept that combines infrared and air drying. The energetically coupled air hood is heated solely by the IR waste heat and thus does not require its own heat source.

DynaLayer

DynaLayer

DynaLayer, the latest curtain coater from Voith, enables an excellent application of color with an unprecedented compact design that works completely without an enclosure. Instead of the usual costly enclosure including an energy-intensive air conditioning function, a thin air shield protects the curtain against disruptive influences from outside.

Web stabilizers

Web stabilizers

With Voith web stabilizers, wrinkles, sheet fluttering, edge lifting, frequent breaks or a long downtime due to tail threading problems are a thing of the past.

EvoDry

EvoDry

The EvoDry steel cylinder offers outstanding performance and allows heat transfer to be increased by up to 10%. A uniform surface temperature over the entire width of the cylinder also enables gentle drying for optimum paper quality.

EcoChange W

EcoChange W

Through the combination of the Sirius winding system with the EcoChange W turn-up device, excellent and reliable reeling with highest turn-up efficiency and reduced energy consumption is guaranteed.

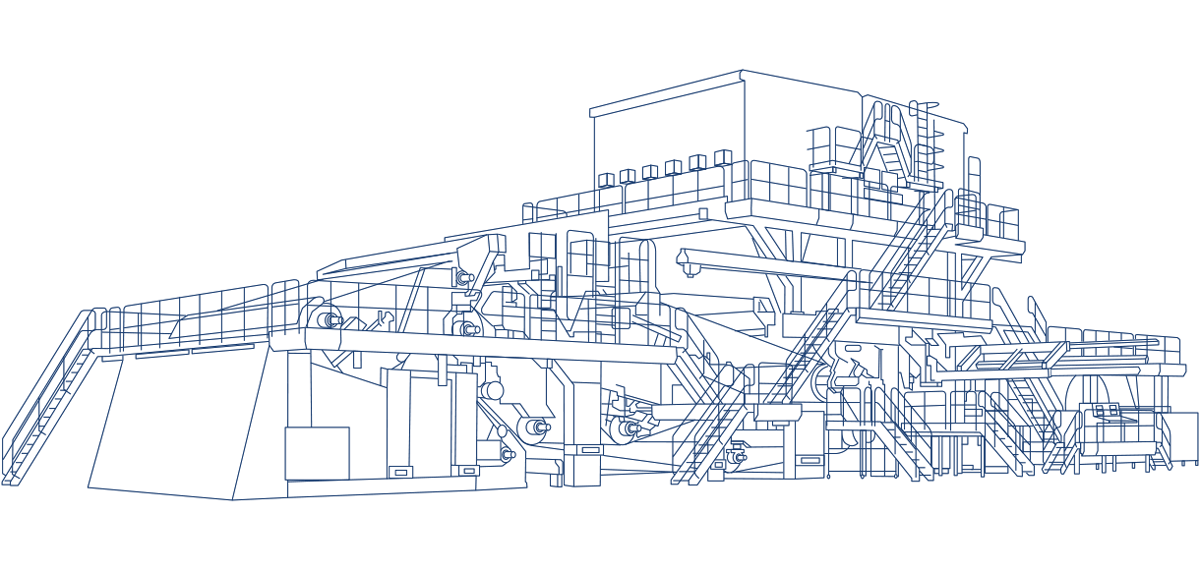

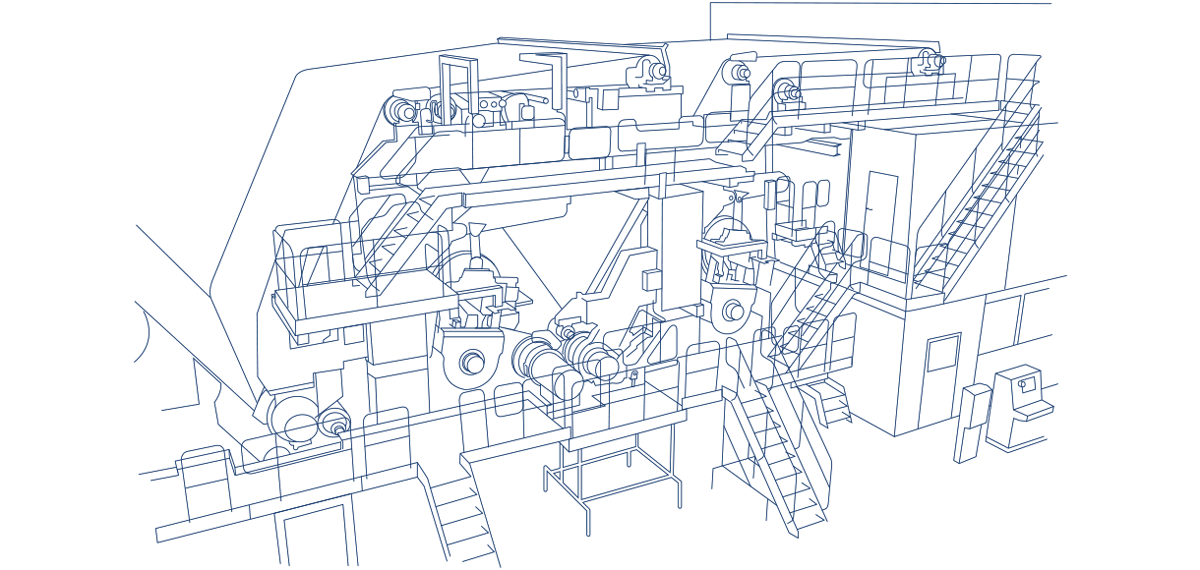

MasterJet Pro

MasterJet Pro

The new MasterJet Pro headbox represents a milestone in headbox development. It improves paper quality and at the same time allows substantial savings in energy costs.

AquaLine Zero

AquaLine Zero

With Voith's AquaLine Zero water management concept, significant water savings are realized due to closure of the water circuits. CO2 emissions can be reduced by about 10% at the same time.

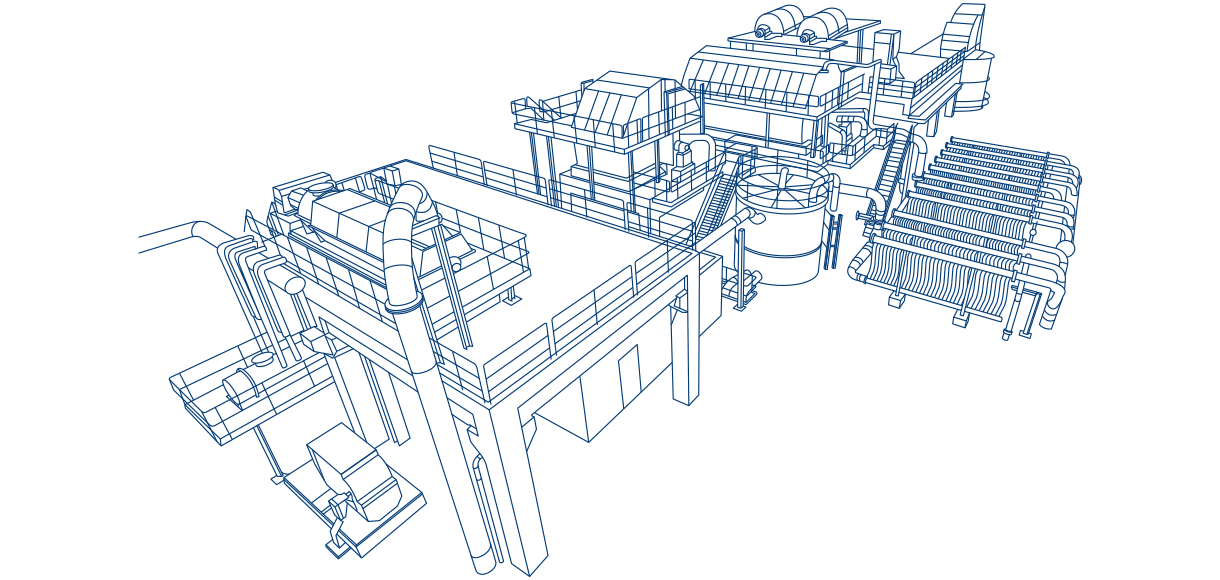

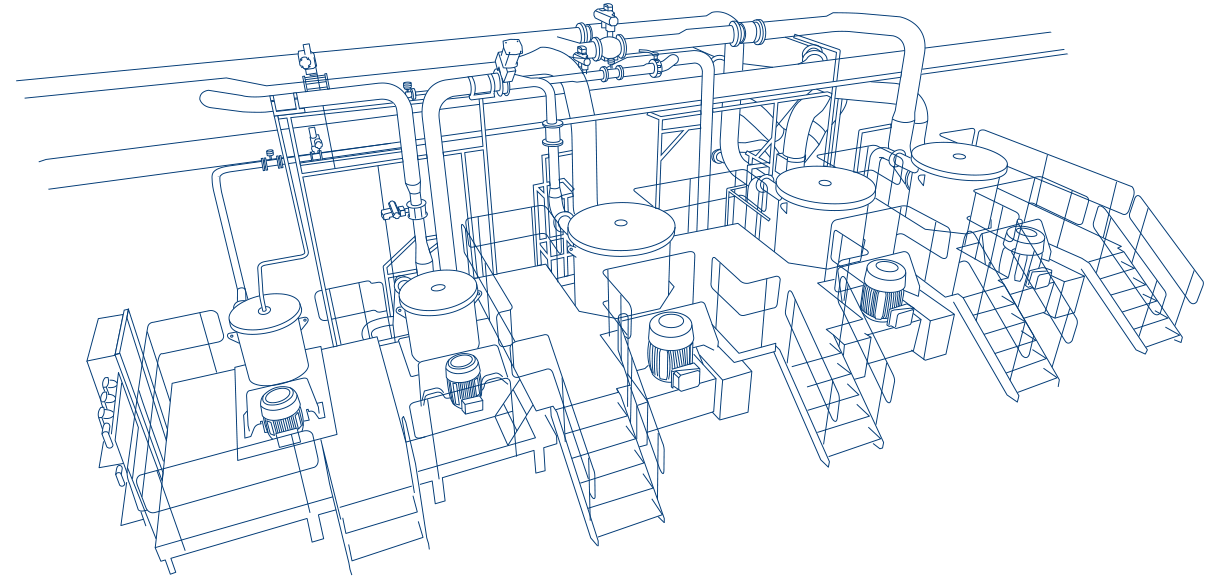

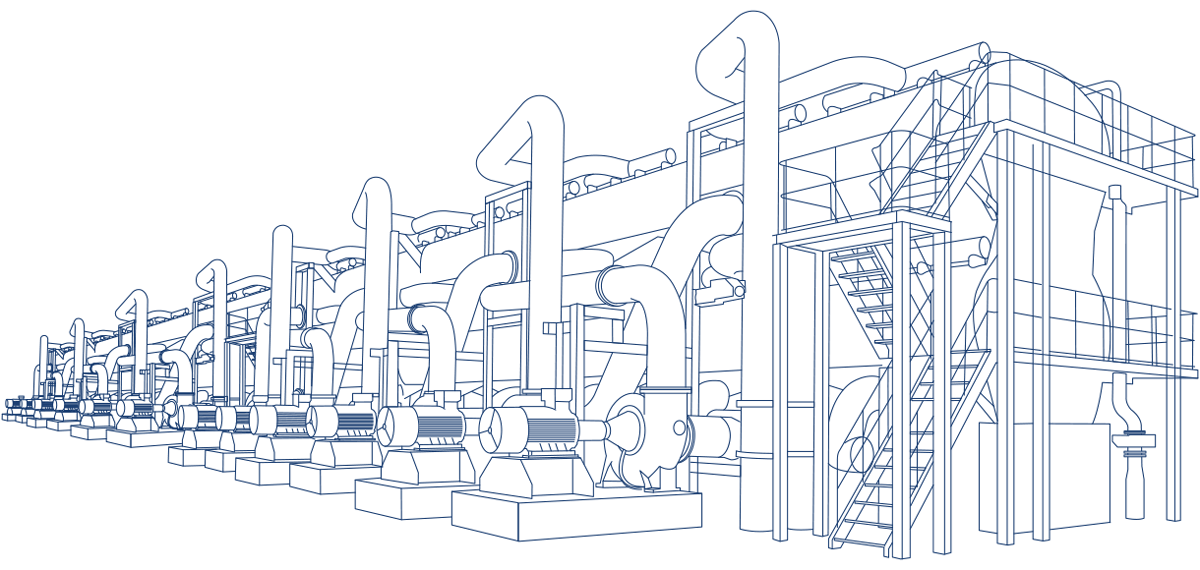

BlueLine DIP process

BlueLine DIP process

More than 60% of the worldwide production of graphic papers is produced with Voith stock preparation systems. With the BlueLine DIP process, Voith offers leading technology and energy efficiency for the processing of recycled paper.

BlueLine OCC process

BlueLine OCC process

With over 85 complete BlueLine OCC systems installed, Voith products are among the world's leading solutions for energy-efficient and robust recycling of recovered paper and cardboard. Minimum energy consumption is achieved, e.g. through an elevated consistency level, fewer components and Voith’s Feed-Forward Principle.

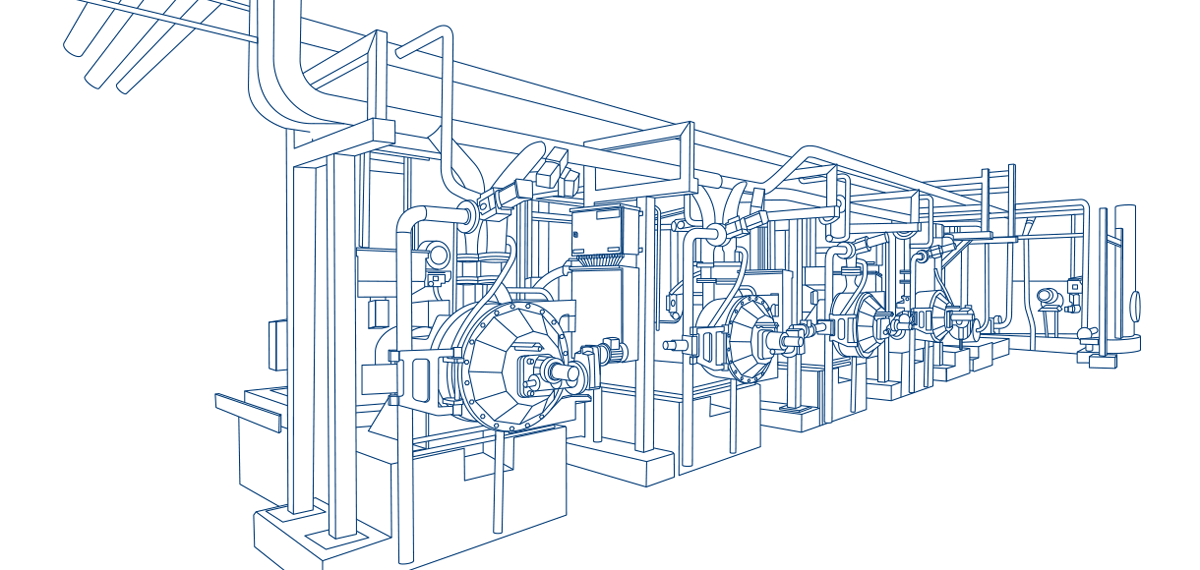

IntensaPulper IP-V

IntensaPulper IP-V

IntensaPulper IP-V is a pulper that offers especially energy-efficient pulping of virgin fibers, clean recovered paper or broke in batch or continuous mode. In combination with Voith’s IPV Rotor, energy savings of up to 30 % are achieved.

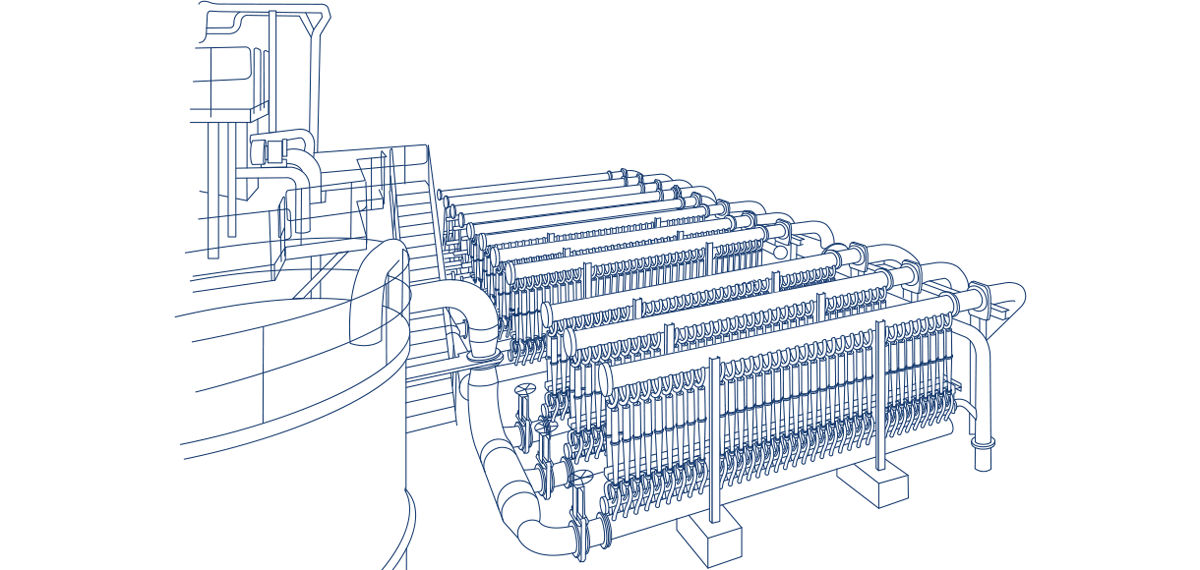

LowEnergyFlotation (LEF)

LowEnergyFlotation (LEF)

LowEnergyFlotation (LEF) is a patented low-energy deinking flotation with minimal fiber loss. It effectively removes inks and hydrophobic contaminants from recovered paper and reduces the energy demand by up to 50% compared to a standard application. Existing flotation plants can be rebuilt to LEF technology.

MultiFoil rotor

MultiFoil rotor

MultiFoil rotors are the ideal combination of the highest screening quality and throughput rates in stock preparation and approach flow. They were developed for energy-saving screening and are suitable for the use in Voith screens and machines of other manufacturers.

HiCon 2.0 technology

HiCon 2.0 technology

The HiCon 2.0 technology for disc filters was specially developed to dewater suspensions with high stock consistencies. Due to the high stock consistency noticeably less pumping capacity is required and consequently significant energy savings can be realized.

IntensaScreenDrum

IntensaScreenDrum

The IntensaScreenDrum is a newly developed drum screen for efficient reject washing. The fiber loss is minimized thanks to optimized retention time and 3D shower nozzles.

IntegraScreen

IntegraScreen

The flow-optimized machine housing results in constant flow and pressure conditions around the screen basket. The thickening of the reject is decreased due to the additional reject dilution as well as the integration of the reject recirculation into the machine. As a result, fiber losses are reduced.

EclipseR Rotor

EclipseR Rotor

Thanks to the new rotor design and innovative foil geometry of our EclipseR Rotor, the energy consumption in the screening process can be reduced by up to 35 % compared to former models.

Pluralis

Pluralis

Our proven Pluralis design offers effective refining of the pulp in the stock preparation. Thanks to the special arrangement and shape of the bars, the fibers can be treated with low intensity resulting in the best product qualities.

EcoMizer

EcoMizer

The internationally proven EcoMizer concept of axially injected backflush water allows minimal fiber loss with high operational reliability.

C-bar baskets

C-bar baskets

C-bar screen baskets offer precise, reliable technology for centrifugal and centripetal pressure screens. All kinds of stock can be reliably screened, even with high stock consistencies and rotor loads.

Star Rotor

Star Rotor

With the right technology, efficient pulping of virgin pulp and recovered paper in stock preparation leads to reduced specific energy consumption.

FloWing

FloWing

Compared to filter discs with a flat profile, FloWing achieves an increase of more than 56% in filter surface area with its patented, wing-shaped profile.

TheWall

TheWall

The innovative design of TheWall allows uniform distribution and feeding of the pulp. This is achieved by the rotor which is equipped with feeding vanes and the strategically arranged distribution teeth.

BaglessPlus

BaglessPlus

The consistently high filtrate quality over the entire service life of the BaglessPlus filter discs leads to a significant reduction of fiber loss and fresh water consumption.

InduraClean

InduraClean

Due to the lower pressure drop, the InduraClean IDC-4 cleaners have a lower energy consumption, which reduces operating costs considerably.

CleanLine Excell

CleanLine Excell

Voith’s CleanLine Excell is an efficient cleaning system for consistent and uniform cleaning of the surface and structure of forming and press fabrics.

HydroSeal

HydroSeal

With HydroSeal the integrated lubrication of the sealing strips requires less water and energy to operate. That leads to a reduction in the consumption of fresh and waste water, as well as energy consumption.

Servolution

Servolution

Our tailored service packages focus on results. We improve performance, increase productivity and meet output objectives for our customers’ paper mill. This case is just one example how we can support you with our service offerings.

FilmLube

FilmLube

Thanks to its novel design, FilmLube ensures uniform lubrication at all times. This results in a more uniform moisture cross profile, improved paper quality and lower water consumption.

+Up

+Up

- With +Up, your tissue machine starts up an average 50% faster than with standard felts.

- The Efficiency Add-On +Up generates benefits of up to 100,000 €/year in additional production volume.

- It is 100% compatible with all felts in tissue, for example, Infinity, TissueFlex and Evolution.