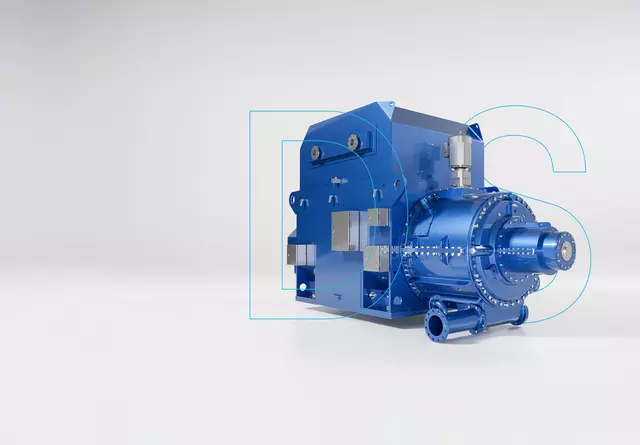

The optimized electromechanical drive system

The E-Pack DS is your ideal drive system upgrade for numerous industries, from chemicals and petrochemicals to power, oil and gas. Its small footprint, low weight and high efficiency help you transition to electric with confidence.

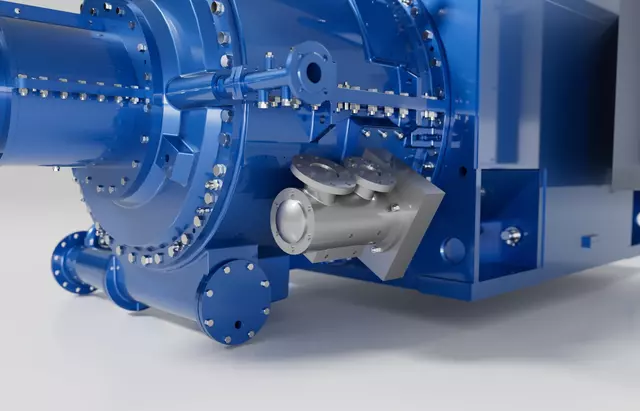

This unique synchronized package featuring an electrical machine with an integrated gearbox sets a new benchmark for electric drivetrains. It can be deployed in purely electric new developments or retrofitted in existing structures to replace gas and steam turbines.

Robust design features promote durability, lower wear, and streamlined maintenance for a low total cost of ownership (TCO). Create your perfect package from our flexible portfolio and optimize your operations today.

Integrated partners for everything you need

Voith and ELIN Motoren combine the benefits of the gearbox and motor in a single drivetrain. In this way, they craft perfectly optimized electromechanical drive packages that deliver up to 40 MW.

Enjoy quick and simple on-site installation – plus a unique aligned package supplied by a single source.

All benefits at a glance

Compact

Streamlined design for extra efficiency

Economical

Cut TCO and boost sustainability

Robust

Optimized for safety and durability

Product details

Compact, economical, robust: The key benefits of the E-Pack DS are clear to see. But what do they mean in practice for your operations? Click the headings below to learn more.

Compact

Streamlined design for extra efficiency

At up to 30% shorter and as much as 10% lighter, the E-Pack DS enables greater flexibility throughout your operations. Extra efficiency allows you to make greater use of less space, while added simplicity promotes swifter execution of workflows and orders. All this boosts the bottom line for OEMs.

Added value

- One package, fewer interfaces, less overall engineering

- Torsionally and laterally optimized drive system

- Easier on-site deployment at OEM and end user

- Uses fewer resources and has better CO2 footprint

up to 30% smaller footprint

30% reduced footprint with E-Pack DS from Voith and ELIN Motoren

Economical

Reduce power losses, save money

Featuring minimum gear components and bearings, the E-Pack DS outperforms the overall efficiency of a parallel shaft gearbox by up to 1%. A truly harmonized electromechanical drive package, it typically delivers a return on investment (ROI) within 2-3 years – and boosts profits for 20-30 years.

Added value

- Lower power losses and oil temperatures

- Lower operational costs

- Longer-lasting oil and components

- Environmentally friendly package

Robust

One package, fewer interfaces

Fewer components mean more reliability and efficiency, while

fewer bearings enable improved dynamics. In a further boost

to standardization, the gearbox does not require a foundation.

The gear unit and electrical machine use standard oil supply

and drain lines for easy on-site alignment.

Added value

- Harmonized operation and maintenance

- Less lubrication oil, longer service life

- Better spare parts management

- Optimized earthing concept

Technical features

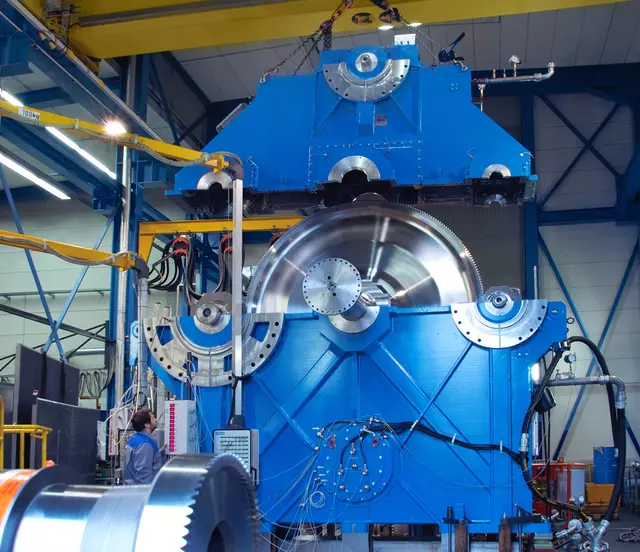

Our planetary gear units combine high power density with low space and weight requirements. By ensuring particularly favorable component stresses for efficient and reliable transmission of torques in turbo drivetrains, our gear units easily meet challenging industrial demands.

| Power transmissions |

Up to 40 MW |

| Speed | Up to 80,000 rpm |

| Rated output torque |

Up to 550,000 Nm |

| Efficiency | Up to 99.4% Up to i = 12 (single stage) |

| Gear ratio | Up to i = 24 (compound star) |

| Housing design | Free-standing casted (standard) and welded housings, compact flange-mounted E-Pack housings for your generator or electric motor |

| Toothing | Double-helical (standard), spur |

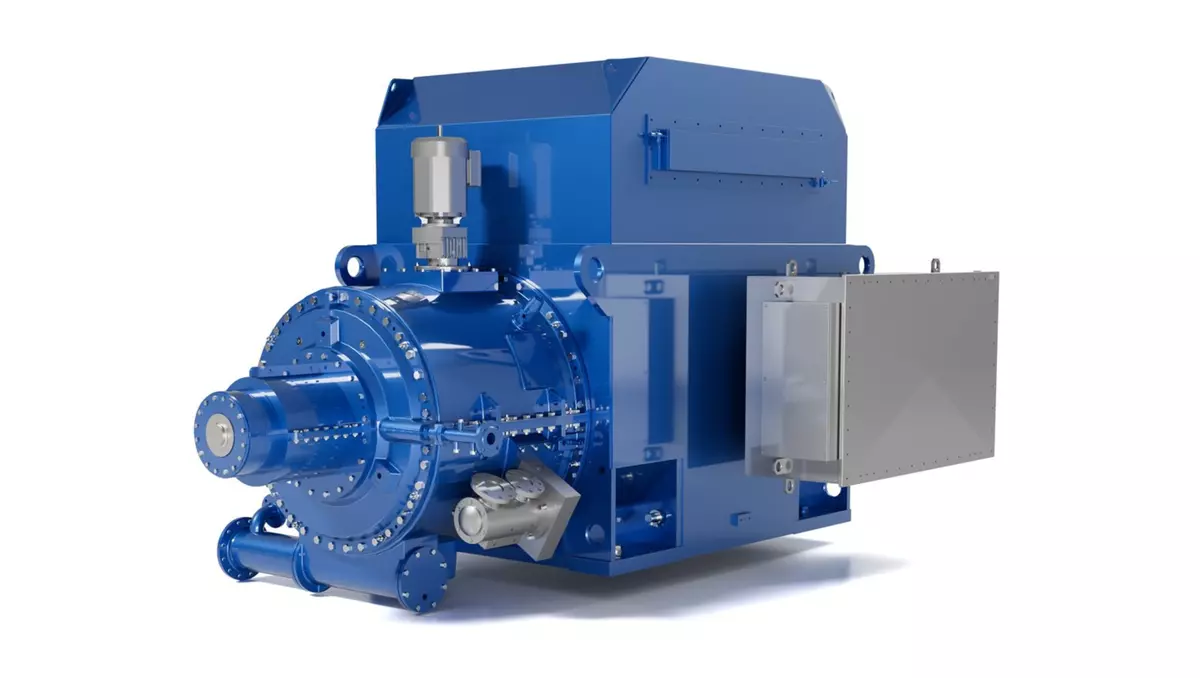

As a unique synchronized package featuring an electrical machine with an integrated gearbox,

the E-Pack DS sets the benchmark for compact and effective electric drivetrains.

The E-Pack DS can be deployed in retrofits and new developments across a range of settings including the chemical and petrochemical industry, oil and gas production, and power generation.

You can further customize your setup via a series of flexible extension options. These encompass the mechanical oil pump turning gears, rotor turning device, and base frame, as well as the lube oil system and jacking oil system.

Applications

The E-Pack DS is your ideal drive system upgrade for numerous industries, from chemicals and petrochemicals to power, oil and gas. Suitable for motor-driven compressors and pumps as well as generators driven by gas or steam turbines, it does more with less space. From generators in mobile containers to offshore applications and beyond, our drive system combines a small footprint, low weight and high efficiency.

Compressors and pumps

Power and speed in a wide range of settings

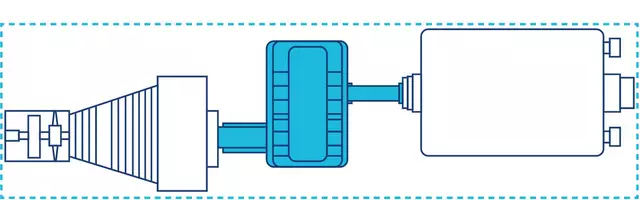

The E-Pack DS serves all segments that require turbo-geared electrical machines. It delivers up to 30 MW of power, even reaching 40 MW in special applications. The low- and high-speed shafts on this epicyclic gear unit can deliver speeds as high as 1,800 rpm and 17,000 rpm respectively – and up to 3,600 rpm and 35,000 rpm in specific cases.

Steam and gas turbine

Boosting efficiency of your turbine

The E-Pack DS connects your steam turbine or gas turbine with the synchronous generator, typically running at 1,500 or 1,800 rpm, while the high-speed shaft on this epicyclic gear typically receives speeds between 3,000 rpm and 10,000 rpm from the turbine. The available power range starts from 1 MW and reaches output values up to 40 MW. Compared to traditional parallel-shaft gear installations, the E-Pack DS will improve the gearbox efficiency up to 1%.

Contact our experts

J.M. Voith SE & Co. KG | VTBS

Hans-Böckler-Straße 7 87527 Sonthofen Germany

t +49 8321 802-0 Send an email