Voith Turbo in Spanga-Stockholm

Our industries: from mining to windpower.

We are at home here. Just like you.

We are at home here. Just like you.

Our markets and our industries. This is where we are at home. Sometimes for many years and decades. With our broad portfolio we are serving the megatrends of our times. We develop reliable, resource-sparing, low-emission products and therefore make an important contribution to safety, efficiency and climate-friendliness.

Drive components and systems from Voith Turbo can be found in a wide variety of industries:

- Mining

- Chemicals & Petrochemicals

- Power Plants – Thermal

- Commercial vehicles

- Machine Engineering

- Oil & Gas Industry

- Paper

- Test Engineering

- Recycling

- Rail vehicles

- Marine technology

- Steel Industry

- Hydro power

- Wind Energy

Contact

Voith Turbo in Hudiksvall

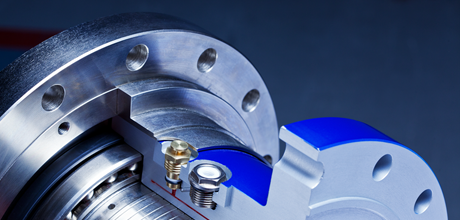

Advanced solutions for torque limiting, process improvement and connection technology

Voith Turbo Safeset manufactures and develops advanced torque limiting couplings, process improving couplings and connection couplings, used to enhance production and protect drivelines in rotating equipment. Development, design, production, marketing and sales are all under one roof, while our corporate network extends worldwide.

Due to their reliability and accuracy our couplings are the long term solution for demanding applications in the mining, steel, marine, energy, rail and recycling industries.

Contact

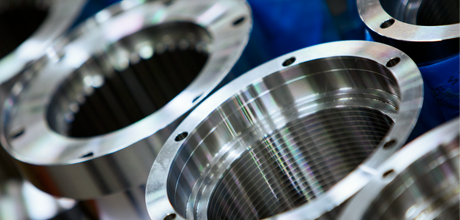

We develop solutions for generations to come

With over 30 years of developing and manufacturing torque limiting and connection couplings, by the inventor Curt Falk, we have unique knowledge in our field. The original patent was taken out in 1978 and production began in Hudiksvall in 1982. Since then, the ground breaking idea is constantly being developed by our expert engineers and researchers.

Expert knowledge and research for innovative driveline solutions

Continuous research and development carried out at our site is the foundation for all product development. We continuously look for new opportunities to create further products and services that enhance driveline dynamics in all areas of industry.

Our in-house technical department designs new drivelines or retro-fit installations for existing drivelines. To maximize the potential of the driveline without risking damage, our engineers simulate different design proposals for individual applications.

Core competence

Friction:

- Optimized design solutions – to apply the Safeset principle to any design.

- Surface treatment – to optimize product

- Huge database of test results

Application:

- Wide area of industry and application knowledge

- High degree of customization

Calculation and simulation:

- Validation and optimization

- System know how

Welding and heat treatment:

- WPS development

- Validation of personnel

- Stable processes by process controls and destructive testings

Bearing and sealing technology:

- Validation

- Ceramics Hybrid bearings

- High load and/or high speed capabilities

Friction based solutions for the connection and protection of drivelines

Voith Turbo Safeset develops and manufactures the most precise torque limiting couplings, process improvers and connection couplings available on the market. Torque limiting couplings protect machinery from overload and maximize production by releasing at a precise set torque. Connection couplings connect and transfer torque, for the most compact and high performance shaft connections. We also offer services to ensure maximum operating performance for the life-span of the driveline.

The extensive industry application knowledge and experience enables our sales team to make the most of every driveline’s specific needs and tailor our solutions to different applications within each industry.

Product range:

Torque limiting couplings:

- SafeSet – torque limiting coupling with instant release

- SmartSet – process improving coupling with slip function

- AutoSet– process improving coupling with slip function and automatic reset

Connection couplings:

- HyCon for shaft-shaft or shaft-flange connections

- HyLoc for shaft-hub connections

- HyGrip for quick-release customer-specific shaft-hub connections

High quality services for the life-span of the driveline

The production and service center in Hudiksvall provides service and maintenance for couplings, expert training of driveline personnel and advanced analysis of driveline dynamics. We regularly carry out scheduled service, maintenance and repairs to reduce life cycle costs, and guarantee continuous operating performance. Voith training sessions at our Hudiksvall service center, offers our customers’ maintenance staff deeper product understanding and in-depth maintenance knowledge.

Worldwide export logistics

At Voith Turbo Safeset we understand the importance of effective export systems and we prioritize the quick delivery of our products by attending to the individual transportation requirements for each of our customers.

Our logistics team always ensures safe handling and transportation for customers, suppliers and dealers worldwide.