Looking to the future

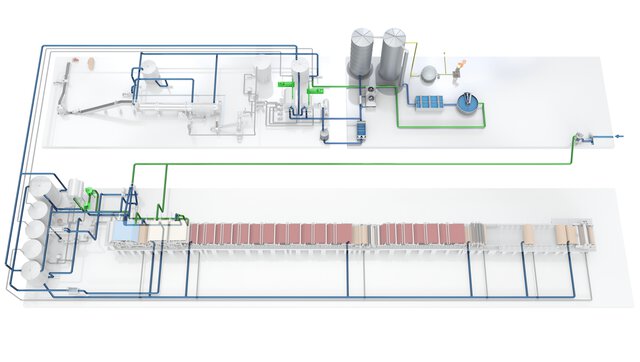

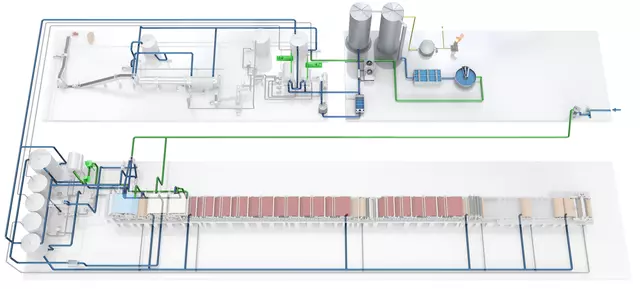

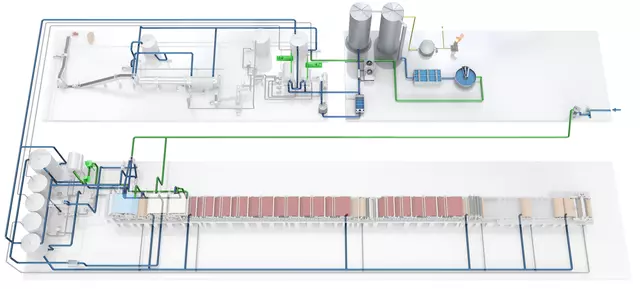

From stock preparation to reel section, Voith’s innovative design concept defines the paper production of the future.

Our vision takes account of all important aspects for a well-balanced overall concept. The maintenance and operation of the facility are simplified, a higher degree of interconnectedness reduces interfaces, a more appealing design ensures a consistent overall look, while at the same time efficiency, safety and sustainability are improved.

More sustainability

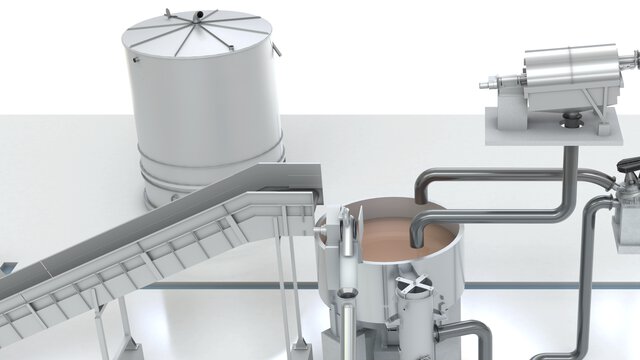

To ensure that our customers can make even better use of the valuable feedstock of primary fibers, we are constantly refining and improving the components of our BlueLine stock preparation system. For example, an optical monitoring system on the rejects belt could identify fiber content and flakes and use these data to optimize downstream processes to minimize fiber loss. Thanks to these kinds of innovations, paper will contain an increasingly larger proportion of recycling fibers without compromising on quality.

Closed water loops are already a reality today, as treated and filtered water from the process is being re-used. This is the key to a significant reduction in water consumption during paper manufacturing. Our vision is to constantly reduce fresh water consumption to an even greater extent.

Our sustainability goals at a glance:

- Lower water consumption

- Reduced energy consumption and CO2 emissions

- Reduction of fiber losses

Thanks to the AquaLine Zero water management system, all the process water (100%) used in paper production can be treated and returned to the production process, which closes the water loop.

Another priority is to reduce energy consumption. Our BlueLine stock preparation systems already use up to 20 percent less energy in the DIP process than standard systems. In the OCC process the energy reduction is as much as 25 percent. And thanks to the use of a new kind of pyrolysis process, it may be possible in future, for example, to provide some of the thermal energy required by recovering thermal energy from biomass, without emitting CO2 in the process. A first model system for this process is set to be launched soon.

In addition, Papermaking 4.0 not only offers a lot of tools for increasing efficiency and quality, but also helps to reduce the resources that your facility uses. Because sustainability in the paper manufacturing process can only be optimized efficiently if all cycles, consumption data and interdependencies are taken into account.

German Sustainability Award Design 2023

Winner of prestigious award

Voith Paper's XcelLine paper machines won the third German Sustainability Award (DNP) in the Design competition, Vision category. Already today, Voith's XcelLine paper machines are characterized by significantly reduced energy consumption, increased utilization of the paper fiber's potential, and significantly reduced water consumption. Voith Paper's visionary design study for the paper production of the future strives for CO2-neutral paper production that relies on alternative energy sources and does not require fossil fuels.

Find out more about this success

Closed water loops are already a reality today, as treated and filtered water from the process is being re-used. This is the key to a significant reduction in water consumption during paper manufacturing. Our vision is to constantly reduce fresh water consumption to an even greater extent.

Our sustainability goals at a glance:

- Lower water consumption

- Reduced energy consumption and CO2 emissions

- Reduction of fiber losses

Another priority is to reduce energy consumption. Our BlueLine stock preparation systems already use up to 20 percent less energy in the DIP process than standard systems. In the OCC process the energy reduction is as much as 25 percent. And thanks to the use of a new kind of pyrolysis process, it may be possible in future, for example, to provide some of the thermal energy required by recovering thermal energy from biomass, without emitting CO2 in the process. A first model system for this process is set to be launched soon.

In addition, Papermaking 4.0 not only offers a lot of tools for increasing efficiency and quality, but also helps to reduce the resources that your facility uses. Because sustainability in the paper manufacturing process can only be optimized efficiently if all cycles, consumption data and interdependencies are taken into account.

Voith Paper's XcelLine paper machines won the third German Sustainability Award (DNP) in the Design competition, Vision category. Already today, Voith's XcelLine paper machines are characterized by significantly reduced energy consumption, increased utilization of the paper fiber's potential, and significantly reduced water consumption. Voith Paper's visionary design study for the paper production of the future strives for CO2-neutral paper production that relies on alternative energy sources and does not require fossil fuels.

Find out more about this success

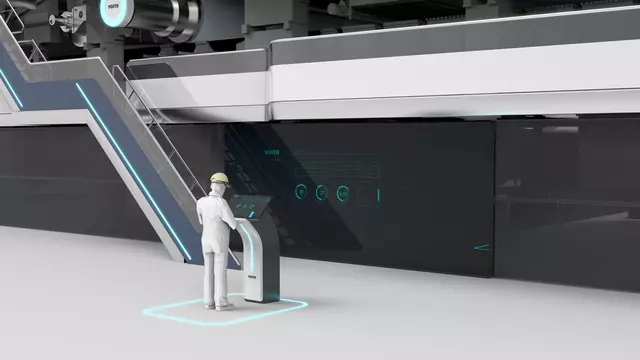

More attractive design

In future, Voith’s expertise as a full-line supplier is also set to be reflected in the design of a plant. From stock preparation unit through paper machine to winder, streamlined structures, high-quality surface finishes, modern materials and specifically selected machine illumination underline the special quality of a Voith production line. All along the XcelLine paper machine, a uniform cladding and continuous walkways are designed to create an uncluttered look.

Our goals for a more attractive design at a glance:

- More modern look

- Uncluttered overall appearance

Focus Open 2022 Baden-Württemberg International Design Silver Award

Award-winning design

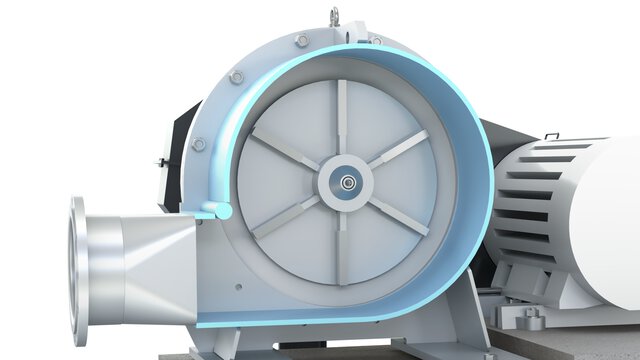

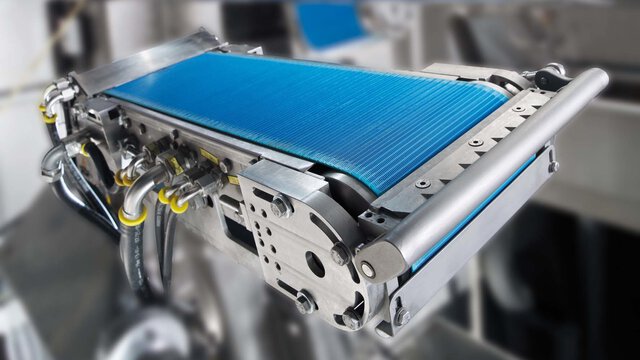

Design experts have awarded the new InfibraFiner refiner from Voith with the Focus Open 2022 Baden-Württemberg International Design Award in silver. In line with our Papermaking Vision, the focus was on an attractive appearance, optimized user interfaces and a ‘clean design’.

Read more about this award

Our goals for a more attractive design at a glance:

- More modern look

- Uncluttered overall appearance

Design experts have awarded the new InfibraFiner refiner from Voith with the Focus Open 2022 Baden-Württemberg International Design Award in silver. In line with our Papermaking Vision, the focus was on an attractive appearance, optimized user interfaces and a ‘clean design’.

Read more about this award

Easier operation

Simple, reliable, intuitive: new concepts make the control and monitoring of paper production easier and more efficient than ever. On a standardized user interface you have an overview of all processes from stock preparation to reel. In this context, the human-machine interface uses a role-based operating concept to adapt to the individual task of the user, whereby each user can configure their own work area to ideally meet their requirements or use our established layout.

Our goals for an easier operation at a glance:

- Standardized, intuitive and adaptive operating concept

- Status display with SmartLight

- Better illuminated work areas

Press Release

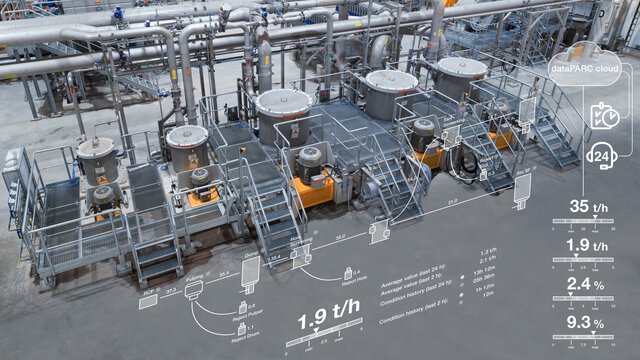

The preparation and representation of relevant data and KPIs will play an increasingly important role. This is made possible by self-configured dashboards and reports, whether in the control room, on office PCs or mobile devices. All information is available to the user wherever they need it at the time.

The smartphone has shown us how simple and intuitive communication between humans and machines makes many areas of everyday life more efficient. In the industrial environment too, machines will in future make all the relevant data and functions a user needs to do their job available via mobile devices, for example, with an attractive and adaptive design.

Easy-to-see SmartLights on individual system components also ensure more efficiency. They show you the status of the machine and if applicable, whether operator intervention is necessary. Optimized lighting of important work areas reduces the potential for errors, simplifies maintenance work and is also part of the user-friendly operating concept.

Our goals for an easier operation at a glance:

- Standardized, intuitive and adaptive operating concept

- Status display with SmartLight

- Better illuminated work areas

The preparation and representation of relevant data and KPIs will play an increasingly important role. This is made possible by self-configured dashboards and reports, whether in the control room, on office PCs or mobile devices. All information is available to the user wherever they need it at the time.

Easy-to-see SmartLights on individual system components also ensure more efficiency. They show you the status of the machine and if applicable, whether operator intervention is necessary. Optimized lighting of important work areas reduces the potential for errors, simplifies maintenance work and is also part of the user-friendly operating concept.

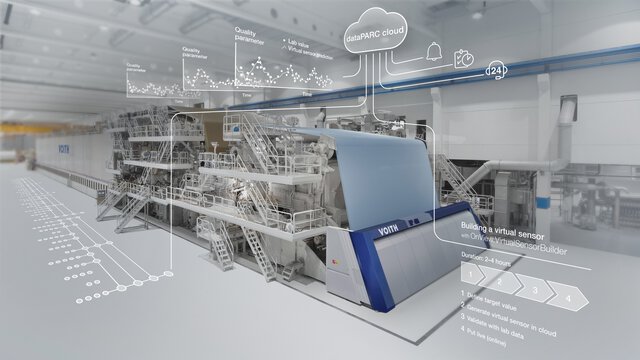

More autonomy

Sensors, field devices, scanners and actuators are already making a wealth of data available to your paper mill and form the basis for comprehensive real-time analyses. In future, however, the data will also enable very fast and reliable responses to changes in condition, which therefore minimizes downtimes because maintenance and servicing can be optimized pro-actively.

Our goals for more autonomy at a glance:

- Continuous process monitoring

- Higher degree of automation

- Self-optimizing production line

In future, digital instrumentation applications will be more widespread and so will be able to achieve more, as they interact with one another and respond to changes autonomously. Intelligent algorithms then ensure that the system optimizes processes autonomously.

Our goals for more autonomy at a glance:

- Continuous process monitoring

- Higher degree of automation

- Self-optimizing production line

In future, digital instrumentation applications will be more widespread and so will be able to achieve more, as they interact with one another and respond to changes autonomously. Intelligent algorithms then ensure that the system optimizes processes autonomously.

More interconnectedness

More complex does not mean more complicated. On the contrary! You can control and monitor all system functions via a platform, and optimize them with the help of data from the cloud. However, in our design concept this platform is also a networked interface to all service functions like ordering spare parts via the webshop, the remote service center OnPerformance.Lab, the video support for troubleshooting OnCall.Video, and many other applications that facilitate more efficient and sustainable production.

Our goals for more interconnectedness at a glance:

- Standardized operating platform for all functions

- Cloud-based data storage and analysis

- Direct interface to service experts and other apps

Our goals for more interconnectedness at a glance:

- Standardized operating platform for all functions

- Cloud-based data storage and analysis

- Direct interface to service experts and other apps

More efficiency

Resource savings, lower maintenance costs or greater autonomy are important building blocks on the road to more efficient paper manufacturing. And Papermaking 4.0 is the key. The Papermaking 4.0 apps provide optimum support to machine operators, paper technologists and maintenance personnel, so that they can focus completely on their core task, which is to produce paper efficiently in the right quality.

Our goals for more efficiency at a glance:

- Cost-saving operation

- Optimized functionality

- High level of availability

- Improved access

- Increased cleanliness

Another priority is to reduce energy consumption. Our BlueLine stock preparation systems already use up to 20 percent less energy in the DIP process than standard systems. In the OCC process the energy reduction is as much as 25 percent. And thanks to the use of a new kind of pyrolysis process, it may be possible in future, for example, to provide some of the thermal energy required by recovering thermal energy from biomass, without emitting CO2 in the process. A first model system for this process is set to be launched soon.

In addition, Papermaking 4.0 not only offers a lot of tools for increasing efficiency and quality, but also helps to reduce the resources that your facility uses. Because sustainability in the paper manufacturing process can only be optimized efficiently if all cycles, consumption data and interdependencies are taken into account.

Our goals for more efficiency at a glance:

- Cost-saving operation

- Optimized functionality

- High level of availability

- Improved access

- Increased cleanliness

Another priority is to reduce energy consumption. Our BlueLine stock preparation systems already use up to 20 percent less energy in the DIP process than standard systems. In the OCC process the energy reduction is as much as 25 percent. And thanks to the use of a new kind of pyrolysis process, it may be possible in future, for example, to provide some of the thermal energy required by recovering thermal energy from biomass, without emitting CO2 in the process. A first model system for this process is set to be launched soon.

In addition, Papermaking 4.0 not only offers a lot of tools for increasing efficiency and quality, but also helps to reduce the resources that your facility uses. Because sustainability in the paper manufacturing process can only be optimized efficiently if all cycles, consumption data and interdependencies are taken into account.

More safety

Well-illuminated work areas, wide walkways without landings, or stairways with lower step heights and glazed handrails don’t just improve the look of the machine. They are also elements of a comprehensive concept to make working on your production line safer. Equally, Voith is working with its own security operations team of highly qualified experts to ensure, for example, that you can be confident that all your sensitive data on the dataPARC cloud.Platform will always remain exclusively in your possession.

Our goals for more safety at a glance:

- Optimization of occupational safety

- Reliable cyber security

You decide how you access your data and control it for the respective application. In this context, Voith is combining maximum privacy, cyber security and top-rate infrastructure with its in-depth industry experience to help you navigate your digital future as our customer.

Our goals for more safety at a glance:

- Optimization of occupational safety

- Reliable cyber security

You decide how you access your data and control it for the respective application. In this context, Voith is combining maximum privacy, cyber security and top-rate infrastructure with its in-depth industry experience to help you navigate your digital future as our customer.

Contact us

Do you have a question or need advice? We are always happy to help! Please send an email or give us a phone call. Together we will find the right solution for you and your application.

t +49 7321 37-0

Voith Paper Social Media

Voith Paper Newsletter

Always get the latest updates on new products and services, projects, campaigns and success stories as well as upcoming exhibitions and conferences – straight to your inbox.