2021-05-19 Voith refurbishment service for the CombiSorter: Extremely robust cast steel allows service life to be multiplied

- Replacement of CombiSorter's basalt inner lining with cast steel is increasing service life and productivity by several years

- From the second refurbishment onwards, Voith Service takes place directly on site

- Worldwide availability for CombiSorter types CSM 12, CSM 12B, CSM 22 and CSM 22B

The developed cast steel is extremely robust and increases the service life and productivity by several years.

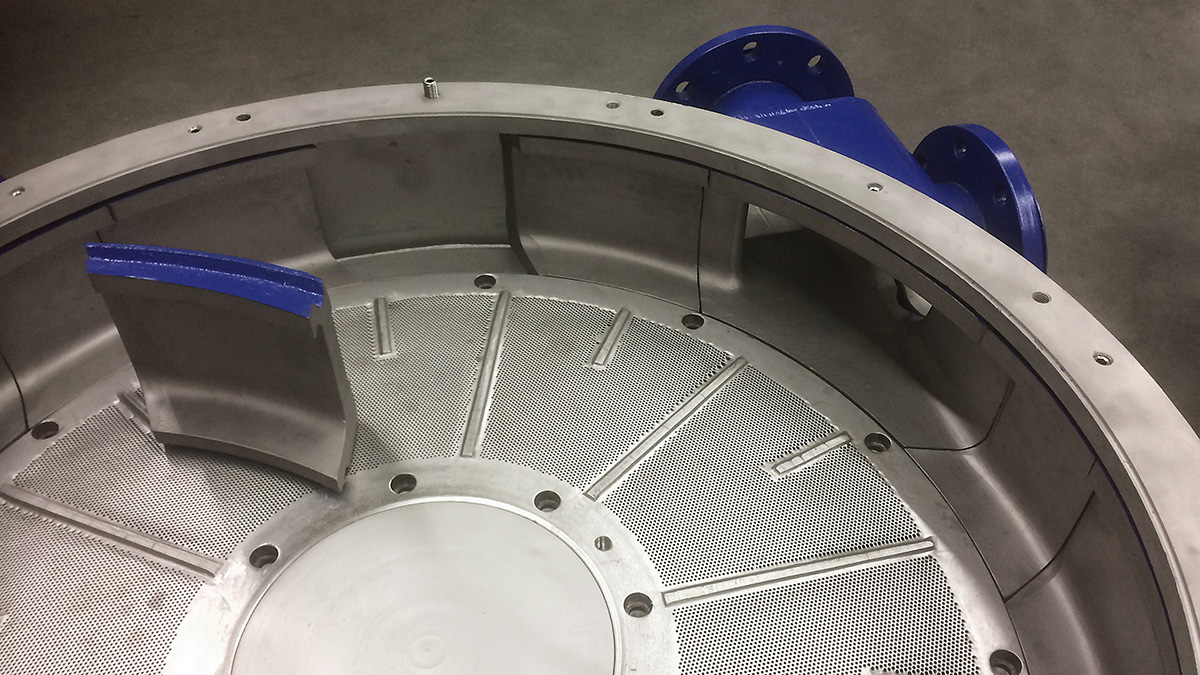

HEIDENHEIM, Germany. The Voith CombiSorter reject sorter separates plastics and light rejects continuously and with high efficiency. No further reject pre-thickening is necessary up to a reject consistency of 30%, resulting in a major economic advantage. During operation, the lower housing is constantly exposed to heavy and abrasive particles. For this reason, basalt inserts were previously used for protection, which often had to be replaced at great expense. Based on many years of experience, Voith has now developed a robust, durable wear part. Voith’s new cast steel part can be used in the CSM 12, CSM 12B, CSM 22 and CSM 22B CombiSorter types.

The advantages are obvious: The productivity of the CombiSorter after the efficient refurbishment service is the same as directly after commissioning with an optimized use of resources. In addition, the service life of the casing lining is increased many times over due to the special cast steel alloy.

Naomi Voith

Global Communication Manager

t +49 7321 37-2209

To increase efficiency, the CombiSorter is taken to a service location during the first refurbishment. Depending on availability, the worldwide workshops offer repair and appropriate replacement housing for the different types. To minimize downtime for each subsequent refurbishment, the service can be carried out directly on site every subsequent time.

In addition to upgrading the CombiSorters, Voith offers many other services at its 20 service centers worldwide. For example, vacuum pumps, disc filters and screw presses can be reconditioned independently of the manufacturer. Reconditioning is only a small part of the comprehensive maintenance service with which Voith supports customers. There are many other customized services for optimizing processes or implementing individual, individually recommended measures to reduce energy consumption.

About the company

The Voith Group is a global technology company. With its wide range of plants, products, services and digital applications, Voith sets standards in the markets for energy, oil and gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 20,000 employees and earns 4.2 billion euros in sales. It has locations in over 60 countries and is one of Europe’s larger family-owned companies.

read more

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and supports customers in significantly reducing their carbon footprint. With its comprehensive automation products and leading digitization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art, digital technologies to increase the availability and efficiency of their systems in all areas of the production process.