2021-07-28 Papermaking Vision: Voith creates visionary design study for the paper production line of the future

- As a full-line supplier, Voith presents a holistic concept for all areas of paper production

- The long-term design study is to significantly increase efficiency and maintainability

- The focus is on the implementation of a "Clean Design" as well as the latest digitalization and automation solutions in combination with artificial intelligence

In a visionary design study, Voith is designing the paper production line of the future. The focus is on improved efficiency and increased ease of maintenance.

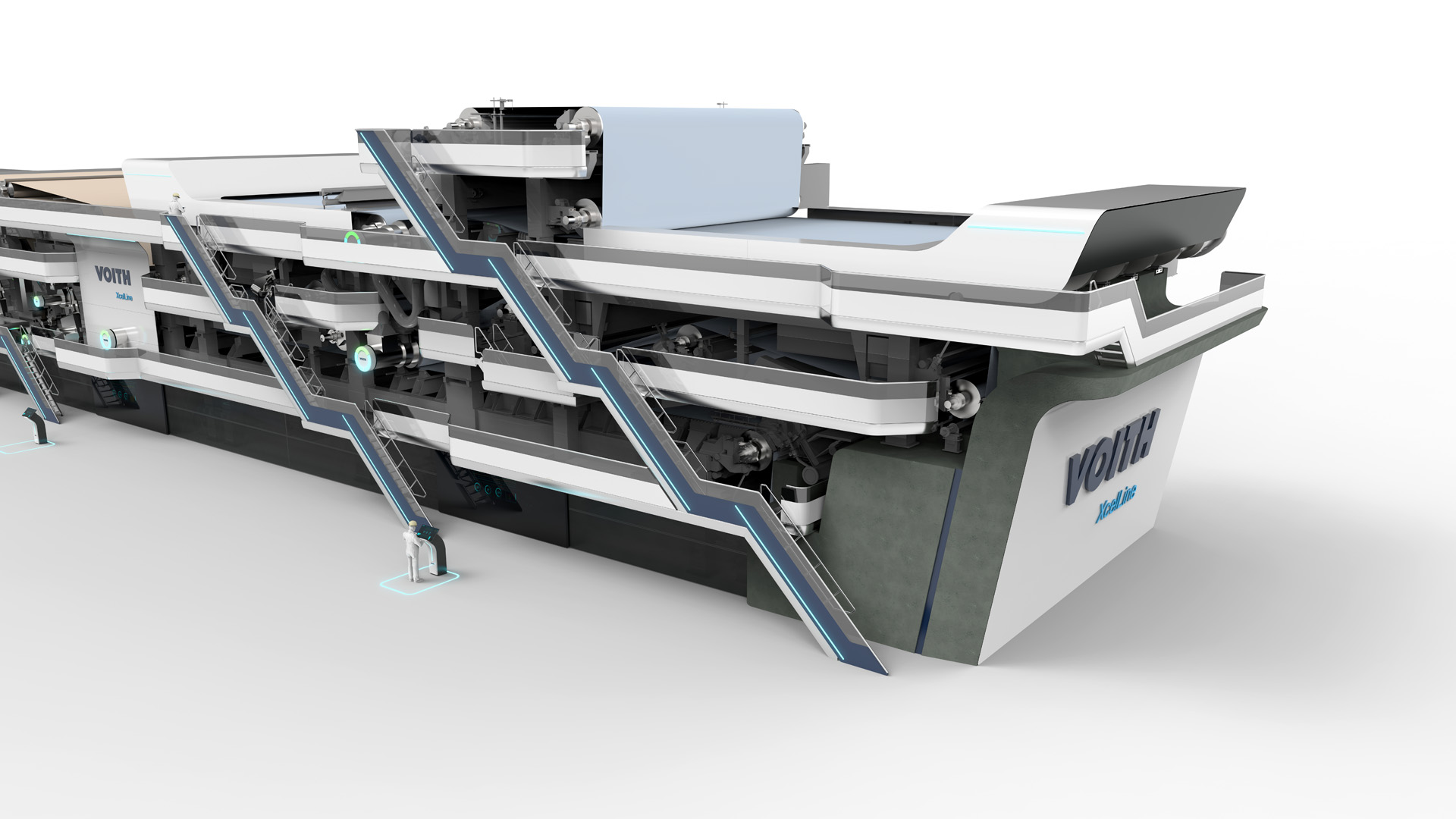

HEIDENHEIM, Germany. With a visionary design study, technology group Voith is creating the paper production line of the future. The design particularly focuses on improved efficiency and ease of maintenance. As a full-line supplier, the company has considered all aspects of the paper production process for an integrated concept. Maintenance and operation of the facility are simplified, a higher degree of interconnectedness reduces interfaces, and an appealing design ensures a consistent overall look, while at the same time improving efficiency, safety and sustainability.

Naomi Voith

Global Communication Manager

t +49 7321 37-2209

‘Clean design’ for greater efficiency and a smooth production process

Special attention was paid to the implementation of ‘clean design’ principles, for example by increasing cleanliness in the wet end. Less contamination reduces the risk of unscheduled downtimes due to web breaks. Consequently, operational reliability and machine efficiency are improved and the production process runs smoothly. Also, scheduled shutdowns are completed more efficiently thanks to more accessible work areas and simpler maintenance procedures. The design concept is a long-term project and will be implemented step by step over the coming months and years.

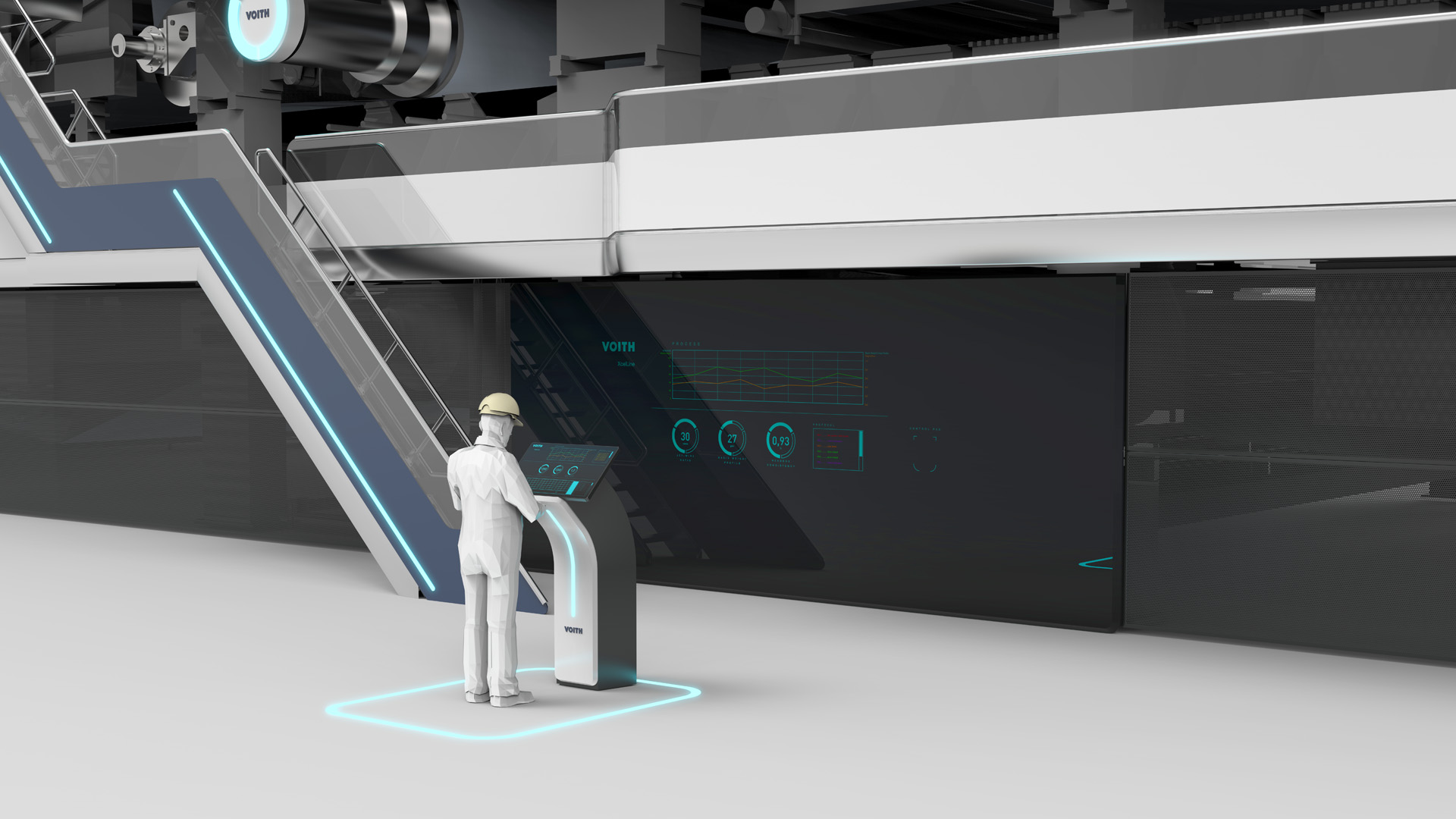

Optimized human-machine interface improves ease of maintenance

As part of the vision for the future, a standardized and intuitive user interface will therefore be introduced from stock preparation through to the reeling. In this context, the human-machine interface uses a role-based operating concept to adapt to the individual task of users, which at the same time improves ease of maintenance. In the future, more efficiency will also be ensured by distinctive SmartLights on individual components of the system. They show the machine status at a glance, and if necessary, whether operator intervention is required.

Automatic data analysis replaces pure monitoring

Papermaking 4.0 solutions, sensors, field devices, scanners and actuators already monitor the condition of machines and the quality of production in real time. In the coming years, automatic data analysis will become even more important and replace pure monitoring. Intelligent algorithms will then ensure that in a very short time, the system autonomously creates the optimal conditions for resource-saving production. In the near future, new apps on the Voith OnCumulus IIoT platform will create complete transparency about all conditions in a paper mill and give paper producers far-reaching optimization potential. "For example, one of these apps, the AI-based OnEfficiency.BreakProtect system, can already provide users with recommendations about how to avoid web breaks," says Oliver Kunerth. Time-consuming and cost-intensive downtimes can thus be minimized, while maintenance and servicing are optimized in a forward-looking manner.

In the future, the OnCumulus cloud platform will also provide a networked interface to all service functions, such as for ordering spare parts via the web store or to the remote service center OnPerformance.Lab, enabling more efficient and sustainable production.

Appealing design for a calm overall appearance

In future, Voith’s expertise as a full-line supplier is also set to be reflected in the design of a plant. In this context, clear structures, high-quality surface finishes and modern materials underline the special quality of a Voith BlueLine stock preparation and XcelLine paper machine.

For more information and details on the paper production of the future please go to: Papermaking Vision | Voith.

About the company

The Voith Group is a global technology company. With its wide range of plants, products, services and digital applications, Voith sets standards in the markets for energy, oil and gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 20,000 employees and earns 4.2 billion euros in sales. It has locations in over 60 countries and is one of Europe’s larger family-owned companies.

read more

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and supports customers in significantly reducing their carbon footprint. With its comprehensive automation products and leading digitization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art, digital technologies to increase the availability and efficiency of their systems in all areas of the production process.