Web stabilizer

Optimum web stabilization and tail threading

With Voith web stabilizers, wrinkles, sheet fluttering, edge lifting, frequent breaks or a long down time due to tail threading problems are a thing of the past.

Voith web stabilizers ensure

- stable web pickup from the dryer

- the best sheet stabilizing

- safe and fast ropeless tail threading

- good pocket ventilation

Product range

| Press section | Dryer section single-tier |

Dryer section double-tier B&P grades |

Dryer section double-tier graphic grades |

|

| Bubble Sucker | x | |||

| TransferFoil | x | |||

| DuoTransferFoil | x | |||

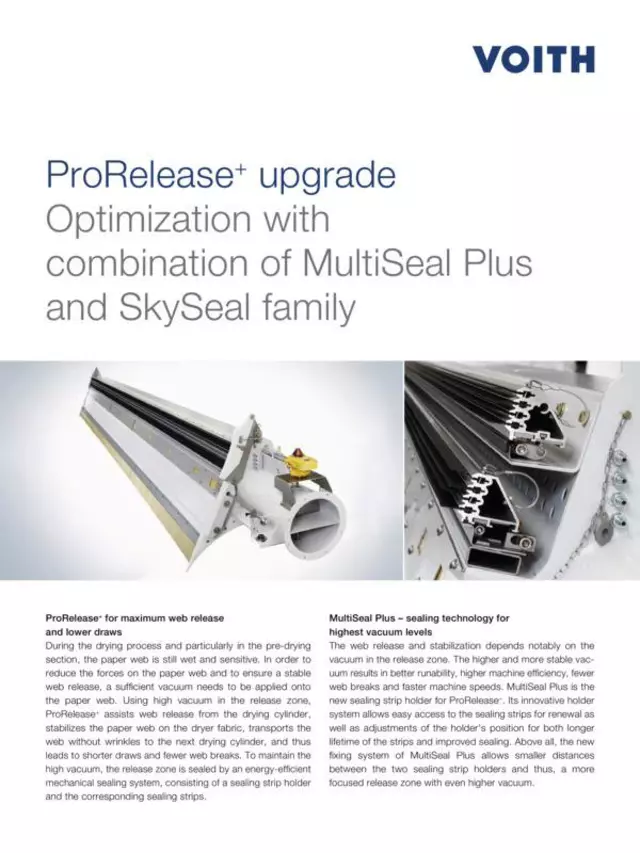

| ProRelease HighEnd | x | |||

| ProRelease+ | x | |||

| DuoStabilizer | x | |||

| DuoFoil | x | |||

| S-Stabilizer | x | x | x | |

| VentiPipe | x | x | x | |

| VentiBox | x | x |

Your contact – How can we help you?

Engineered for success

Rebuild of Jass Schwarza PM 1

Production increase thanks to web stabilization and "Clean Design"

In September 2015, Voith rebuilt the dryer section of PM 1 at the Adolf Jass paper mill in Schwarza, Rudolstadt. The aim of the rebuild was to increase the maximum production speed for low grammages from 1,400 to 1,500 m/min and at the same time maintain the already excellent machine efficiency.

Deep expertise due to many successful installations all over the world

Our Service – Part of Your Business

WebStabilizer Service

Voith will provide you with a comprehensive service suited to your requirements. Even a refurbishment of our web stabilizers is possible. Our service technician ensure that your production starts up smoothly again and that the web stabilizers are functioning properly.

- Maintain the highest level of web stabilization

- Increased production due to fewer sheet breaks and fast speed

- Less fabric deflection, blade wear and better tail threading

- Less energy consumption

- Maximum equipment availability, reliability and safety

- 100% professional OEM services and part

Check out our complete service portfolio

Our service for the paper industry ranges from individual equipment service to maintenance partnerships. Together we will find the right offer for you.