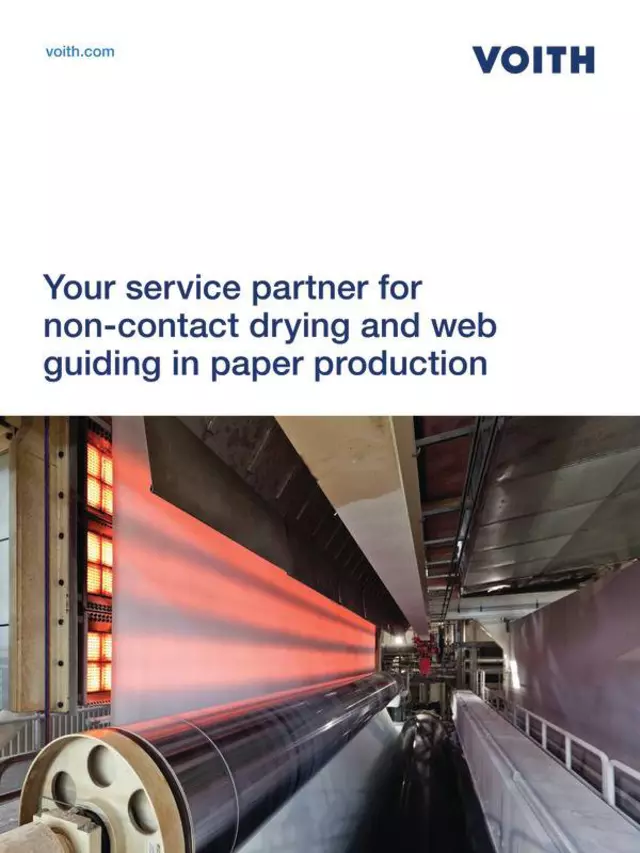

Non-Contact Drying and Guiding

Voith is the only provider in the whole paper and non-woven industry offering a complete range of non-contact drying and web guiding components including high-efficient infrared systems. Our innovative product portfolio combines outstanding performance and highest reliability.

The challenge for non-contact dryers

Non-contact drying systems must...

... be contactless, fast, gentle and energy-efficient, as well as a stable web run and meet small space requirements. It is important that the freshly coated paper or board web is dried as soon as possible to avoid damage to the web surface and deposits on dryers and paper or board rolls. For more than 40 years, we have been dedicated to non-contact drying, being today's only provider of the entire range of non-contact drying and web guiding components in the market. We are your experts for every non-contact drying application!

Our product portfolio for non-contact drying systems

qDry Pro – The future of non-contact drying

qDry Pro is a space- and energy-saving drying concept that combines infrared and air drying. The energetically coupled air hood is heated solely by the IR waste heat and thus does not require its own heat source. Find more details in the product brochure.

CB-Turn – Non-contact web turn device for high-quality paper

Compared to conventional air turns, the bearing surface portion of the CB-Turn is significantly greater and thus reduces the air volume needed to create the air cushion by approximately 30%. Air impingement nozzles and the patented diffuser wings at the web inlet and outlet reduce the amount of air diffused, which as a result stabilizes the air cushion and web run.

Our infrared dryers – InfraAir and InfraElectric

HCB-Turn – Hot-air drying with high efficiency

MCB-Dryer – High level of drying quality and stable web run

Voith MCB dryers are hot air dryers that allow gentle, contactless drying of the paper web with high thermal efficiency. MCB-Dryer benefits:

- Gentle, non-contact drying

- Stable web run

- Highly efficient heat transfer

- Extremely high thermal shape stability

- Energy-saving retraction device

- Low overall height

TurboDryer S – Output capacity increase in the dryer section

Infrared emitters for every application

Manufacturers of coated grades are faced with increasing demands for higher productivity, stricter regulations and lower operating costs. At the same time, process efficiency must continuously improve. That is why our dedicated engineers continuously work to support our customers with innovative emitters to ensure maximum performance and highest availability.

| Input power | Type / Material | CD profiling | Dimensions | |

|---|---|---|---|---|

| HelioX | Up to 14 kW | Ceramic emitter with ceramic cell structure | - |

150 x 200 mm 143 x 204 mm |

| V8 | Up to 8 kW | Ceramic emitter with metal rods | - | 150 x 200 mm

143 x 204 mm |

| V6 | Up to 8 kW | Ceramic emitter with fine metal mesh | - | 150 x 200 mm

143 x 204 mm |

| K 6500 | Up to 6 kW | Metal emitter with metal grid and nozzle plates | 1 - 100% stepless | 150 x 200 mm |

HelioX - More efficient, safer and with lower emissions

With our new gas-fired HelioX infrared emitter, we offer a particularly efficient solution for contactless drying which also impresses thanks to lower emissions. Not only can the new emitter be used to increase productivity, the reduced fire risk also improves safety in paper production. Find all details about the new generation of emitters in our emitter brochure.

HelioX is specially designed for

- high power applications

- minimum emissions and optimal combustion due to increased surface geometry (TOC, NOx)

- highest thermal efficiency through maximized internal energy exchange

- low fire risk due to fast cool-down and heat-up

V8 - The high-power emitter

Due to its high temperature resistant front, consisting of metal bars, the V8 emitter combines robustness and high power over a long lifetime. It is ideally suited for applications where very intensive infrared drying is required and space for drying is limited. The V8 emitter can be used in all kinds of installation positions.

V8 is specially designed for

- high-power applications at maximum temperatures

- long lifetime applications

- demanding conditions (e.g., web breaks)

- homogenous heat transfer due to special frame design

V6 - The economic emitter

If your focus lies on cost-saving versatility, our economic solution V6 is the perfect choice. The combination of ceramic material used for the nozzle plate and the fine-meshed metal grid protecting the surface makes this low-cost emitter very popular among our customers. The V6 grid design minimizes the frame effect, ensures a very homogenous heat transfer and unfolds a high overall efficiency.

V6 is specially designed for

- maximum cost efficiency

- applications demanding long lifetime

- reliable operation due to energy-optimized grid design

K6500 - The robust emitter

For positions next to coaters where harsh conditions occur, the robust K6500 is your perfect choice, because the gas nozzles are optimally protected against outer influences. The emitter plates woven in the metal grid are arranged directly above the nozzles. This optimizes the heat transfer while simultaneously protecting the gas nozzles from splashes.

K6500 is specially designed for

- demanding environments (splashes, shock, air streams)

- cross-directional profiling

- perfect energy transfer leading to low operating costs

- all typical gas types due to its special gas nozzle design

How can we help you? Talk to your personal expert!

FiberDry – Our glass mat dryer

Our FiberDry is the ideal choice for all drying applications in the glass mat industry. Besides the highly flexible modular concept, our customers benefit from our deep drying know-how, which we have accumulated over decades. With the development of the FiberDry, Voith has taken the decisive step to become a full-liner for the glass mat industry. In addition, we offer the optimal service for all machine parts.

Thanks to the modular design of our new FiberDry, we are highly flexible and offer the perfectly concerted solution for drying and curing.

FiberDry advantages:

- Highest glass mat quality thanks to optimized uniform distribution of air speeds and temperatures

- Modular concept allows ideal configuration for each customer and extensive flexibility in production

- Optional infrared module increases productivity, availability and glass mat quality

- Industry 4.0 platform: predictive and condition based maintenance, trend monitoring and virtual sensing

- Designed for minimized contamination for fewer cleaning shutdowns

- Adjustable web width handling system ensures uniform drying of the product and lower energy consumption