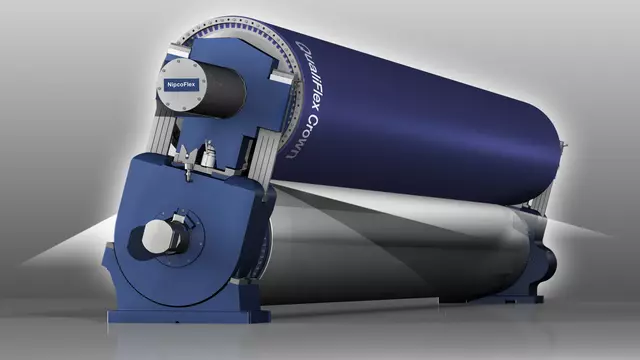

QualiFlex press sleeves

QualiFlex Press sleeves for every requirement

With QualiFlex, you always get the optimum press sleeve – tailored to your paper grade and the specific requirements of your paper machine.

The requirements for press sleeves are different not just for every paper grade but also for individual machines. QualiFlex offers the best solution for this challenge: a product portfolio designed to fit general grade specific requirements, with several possibilities for further individual customization.

QualiFlex Service

Groove measurements on a shoe press sleeve

The inspection of shoe press sleeves is an important service during the whole runtime. With our Surface Scanner, groove dimension measurements on a shoe press sleeve are carried out during a shutdown. The measured values, such as groove depth, width and land width, offer information about the remaining lifetime, product condition and product performance on the machine.

References

QualiFlex sleeve by Voith achieves record run time on PM 4 at Perlen Papier AG

Perlen Papier AG in Switzerland produces coated LWC paper and newsprint on its PM 4 paper machine. The QualiFlex CrownW press sleeve by Voith has now set a record run time on the PM 4.

Voith’s QualiFlex QRun press sleeves deliver $240,000 in annual savings

A leading provider of packaging solutions in the U.S. was experiencing costly problems running their board and packaging machine, including short shoe press sleeve life and other inconclusive failures. The company asked Voith to assess the problems and recommend a solution that would improve production in the current run conditions.

Voith’s QualiFlex QRun press sleeve brings mill back to high operation capacity

A leading provider of packaging solutions in the U.S. recently changed from Voith QualiFlex QRun shoe press sleeves to alternate sleeves provided by another company. As a result, the board and packaging machine was tested in a competitive trial, and the machine was running significantly slower on the competitor’s sleeves. The company asked Voith to assess the performance of those sleeves and recommend a solution that would improve machine speed and overall production.