Voith Plug & Drive H2 Storage System: Heavy Duty, zero Emissions.

As flexible as diesel and as clean as electric

Hydrogen drive systems combine the best of two worlds. They are as flexible as conventional combustion engines and offer comparable refueling times. At the same time, they are emission-free on the road – at least locally, and zero emission if green hydrogen is used.

As an energy source, hydrogen (H2) offers the dual benefits of long range and high efficiency. “Experts believe that in terms of cost-effectiveness, hydrogen will already outperform conventional diesel systems in some applications by between 2025 and 2030,” says Patrick Seidel, Product Owner H2 Storage Systems, Voith's solution for heavy goods vehicles that is currently undergoing testing.

As well as for long-distance transport, the Plug & Drive H2 Storage System is set to prove effective in many other applications. “In the entire off-road segment, for example in construction site vehicles, purely battery-electric solutions often simply cannot meet all the requirements,” says Patrick Seidel.

Getting even heavy loads to their destination with no emissions

A wide range of possible applications in electricity generation, heating and industry shows the enormous potential of hydrogen. In the transport sector too, it is becoming clear that hydrogen in the form of the fuel cell or H2 combustion engine is set to play a substantial role, not in competition with battery-electric vehicles but as a complement to them. When it comes to zero-emission solutions for commercial vehicles – especially over long distances – there is no way around H2. Because hydrogen drive systems already allow ranges of up to 1,000 km. Whether for heavy goods transport, long-distance coaches or trains, the replacement of diesel by H2 is in the air. Or to put it more precisely, “in the water”. Hydrogen is also an interesting option for aircraft or ships.

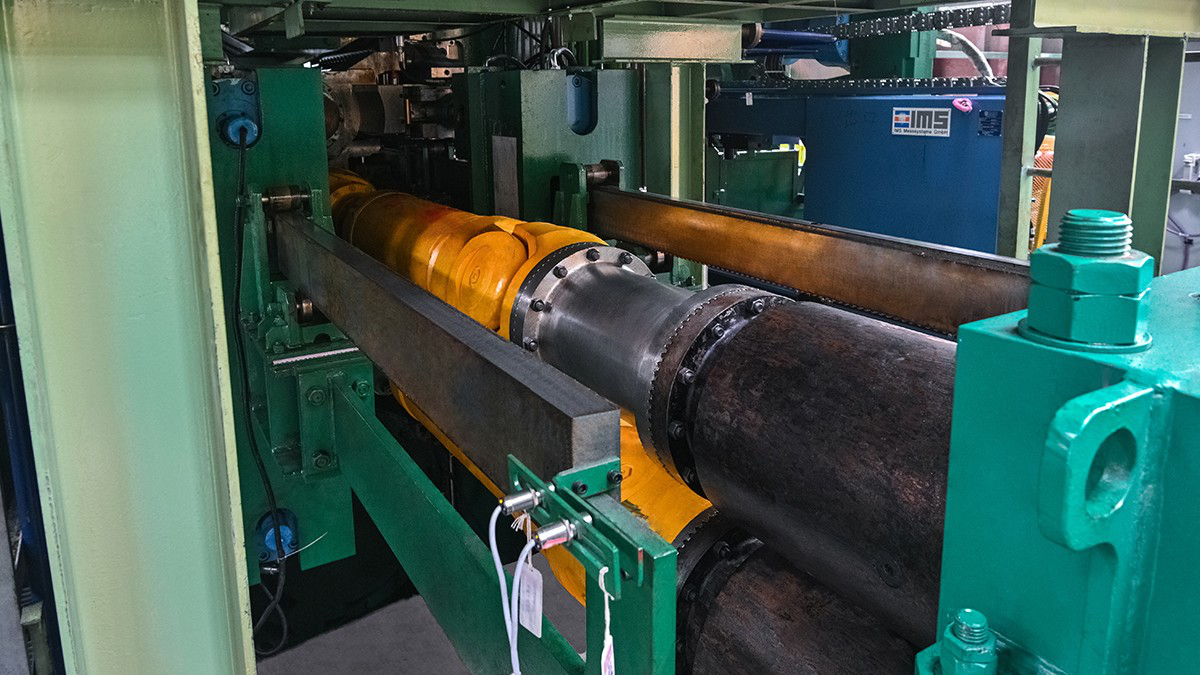

Voith uses pre-impregnated fibers known as TowPregs as the material for the storage tank. This material allows for high pressures of 700 bar and consequently, a compact design.

Configurations of Voith Plug & Drive H2 Storage System

Variant 1:

Basic H2 Core Module with a capacity of 56 kg and weight of 982 kg.

Variant 2:

Basic H2 Core Module plus one side tank with a capacity of 68.5 kg and weight of 1,167 kg.

Variant 3:

Basic H2 Core Module plus two side tanks with a capacity of 75.7 kg and weight of 1,243 kg.

Variant 4:

Two basic H2 Core Modules with a total capacity of 112 kg and weight of 1,909 kg.

Compact installation space, long range

Voith hydrogen technology goes into series production in 2024

Background: Will hydrogen really drive us in the future?

Worldwide, the energy transition is in full swing. Decarbonization, i.e., the avoidance of CO2 emissions, calls for a shift away from the fossil fuels oil and gas – and as well as battery-electric mobility, is accelerating another megatrend: hydrogen drives. There is scarcely a country worldwide that has not developed a national strategy in this regard. In particular, some countries that have (previously) had large oil reserves are leading the way. One such example is Saudi Arabia, whose NEOM project will create an entire city that is set to become the global center for the hydrogen industry.

There are many good reasons why H2 is regarded as the energy source of the future. Most important is its flexibility in use. Hydrogen can cover a host of applications that currently involve the refining of crude oil. However, H2 does not produce harmful CO2 but instead “emits” H20. So what runs out of the exhaust pipe is only water. Naturally, only green hydrogen that has been produced using water and regenerative energies like solar, hydropower or wind power is regarded as climate neutral.

“Producing electricity from water”: In electrolysis, H2O produces hydrogen that can be stored virtually loss-free. If the energy required for the process comes from renewable sources, it is referred to as green hydrogen.

Global H2 demand