VSP marine propulsion system: Precise installation of wind turbines at sea

Offshore wind farms are growing worldwide. The vessel that installs them on the open sea has to be able to maneuver with pinpoint accuracy, which calls for a special propulsion system.

Electricity is moving the world

More people, increasing digitalization and progressive electrification are some of the reasons why the demand for electricity is increasing worldwide. To generate electricity climate-neutrally and drive the energy revolution, green energy sources are playing an increasingly important role.

The megatrend behind this development is decarbonization. To replace large fossil-fueled power plants carbon-neutrally, there is no way around wind power. And specifically, wind farms at sea, i.e., offshore. Because a much greater energy yield can be generated at sea than on land. At the end of 2021, the more than 10,300 offshore wind turbines installed around the world had a total capacity of some 50 gigawatts, a trend that is rising sharply.

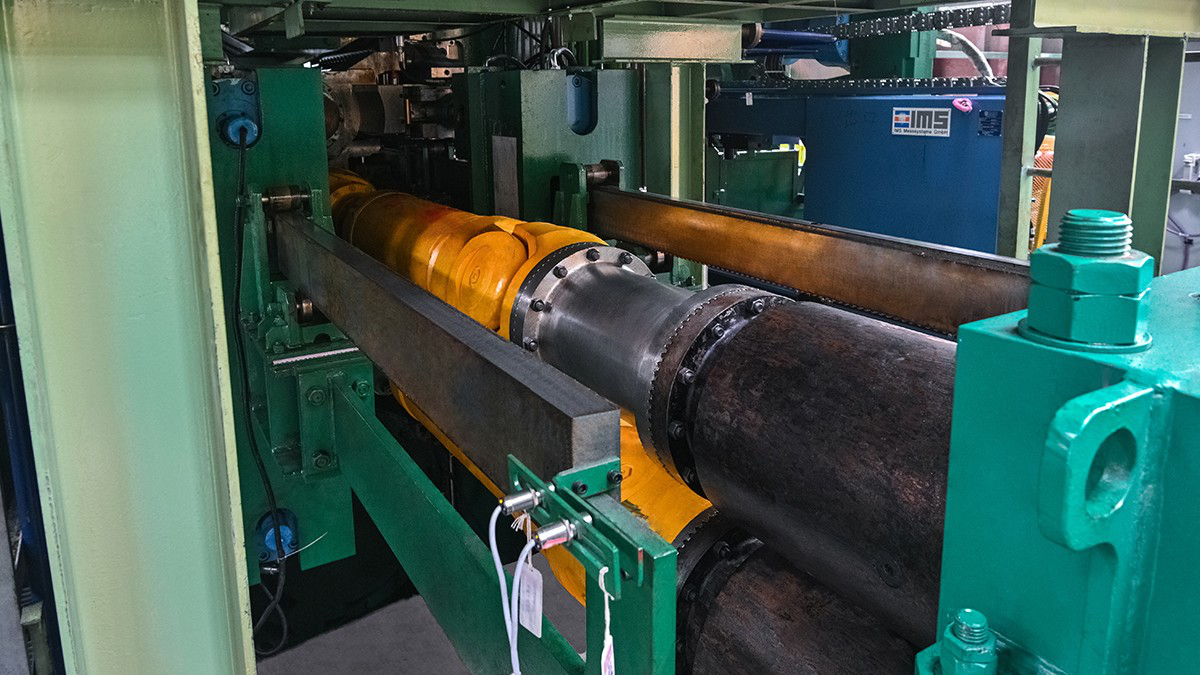

A major challenge when building offshore wind turbines is their installation. Special jack-up ships known as Construction Support Operation Vessels (CSOV) need to position themselves with pinpoint accuracy and then hold this position precisely. One such vessel is the Bold Tern, operated by Norwegian shipping company Fred. Olsen Windcarrier. Instead of conventional screw propellers, this vessel is fitted with Voith Schneider Propellers (VSP). They are the most powerful propellers that Voith Turbo has ever delivered.

The iVSP-App enables an in-depth look into the mechanics and hydrodynamics of the Voith Schneider Propeller (VSP) and its unique propeller forces.

Deployed on the Bold Tern in the North Sea

Installation of an offshore wind turbine in the North Sea

Loading in the port

The Bold Tern and its sister ship Brave Tern are optimized for the transport of massive offshore wind turbines. On the more than 3.200 m2 of open deck space, there is room to transport the masts, rotors and nacelles of several wind turbines. Each vessel can carry a load of more than 9,000 t. The 60 cabins can accommodate the team of up to 80 people responsible for building the facility.

Getting to the offshore wind farm

The deck of the Bold Tern measures 45 meters. This still makes it much shorter than the massive rotor blades of modern offshore wind turbines, which are up to 100 m long and protrude far out over the sea during transport. The blades are made from fiber-reinforced plastics, as these materials offer very good mechanical properties and a low weight. Nevertheless, due to their enormous dimensions each rotor blade can weigh 25 tons or more.

Precise positioning at construction site

As soon as the Bold Tern reaches the construction site, four impressive lifting columns raise the vessel several meters out of the water and ensure it stands securely. This allows wind turbines to be safely installed to a depth of 60 meters.

3,900 kW is the output of the most powerful VSP that Voith Turbo has manufactured to date. Three such propellers are installed in the Bold Tern. This is equivalent to the performance level of exactly 13.8 of the current Porsche 911 Carrera.

The three Voith Schneider Propellers type VSP 36 at the stern are crucial for a successful “parking procedure” without drifting and swaying. With an output of 3,900 kW each, they provide the Bold Tern with excellent maneuvering characteristics and ensure that it lifts out of the water at exactly the predetermined position, even in rough seas.

Installation of a new wind farm

The world’s first offshore wind farm off the Danish coast in Vindeby was commissioned in 1991 and had an initial capacity of 450 kW. With a hub height of 35 m and rotor diameter of 35 m, the turbines represented a modest beginning. Current wind turbines like the one mounted here reach higher out of the North Sea than Cologne Cathedral, whose towers are more than 157 m high. With a rated output of six megawatts, one such turbine can theoretically supply energy to 3,500 households.

157 m and more is the hub height of modern wind turbines. That is taller than the towers of Cologne Cathedral.

The rotors of modern offshore wind turbines have a diameter of more than 150 m. The Bold Tern’s massive crane lines them up directly with the hub at a dizzying height. Even though there may be no more than a light breeze blowing when this procedure is carried out, the precise maneuvering of the rotor blades to within just a few centimeters requires substantial skill and a lot of experience. Otherwise, both the turbine components and the team would be in immediate danger.

Quality control and commissioning

The construction of these “green giants” is a challenge every time, even for the highly specialized team on board the Bold Tern. When installing the foundations of the structures, use is made of the inherent weight of the plinths and the ocean currents – especially the change between high and low tide – to achieve precise positioning. Above water, the Bold Tern’s crane enables lifting heights of up to 157.5 m above the deck.

Bungling the construction work is strictly forbidden. Because the process-compliant installation of offshore wind turbines, from foundations to rotor blade tips, is the prerequisite for effectively converting wind into energy on a permanent basis. The equipment has to withstand the rough maritime climate including the dreaded corrosion and material fatigue, lighting strike and biofouling. In the end, the team has always pulled it off. And today is no exception: The new wind farm is going online – and for many years will supply thousands of kilowatt hours of green electricity from wind power.

Mounting huge components under extreme weather conditions: The teams from the Construction Support Operation Vessels consist of experienced experts, who keep a cool head and a steady hand when carrying out precision work on the open sea.

eVSP: The electrification of Voith Schneider Propellers