Voith Turbo Industry:

A driving force behind the energy transition.

In the past, Voith Turbo’s Power, Oil & Gas unit focused on technologies and components for thermal and combined cycle power plants and for the extraction, transport and processing of oil and gas. In the meantime, the company is naturally working with future-focused products and solutions in this segment too. “On the road to decarbonization, we are supporting our partners with several strategies,” says Alexander Schust, Vice President Global Sales at Voith Turbo.

The contributions made by Voith Turbo’s Power, Oil & Gas unit to reducing and preventing CO2:

Firstly, increasing the energy efficiency of fossil-fired power plants and the infrastructures for extracting oil and gas. “As a bridging technology, gas in particular will be with us for some time yet, until the regenerative energies have caught up,” says Schust. “With numerous components we are helping to ensure that the entire process, from extraction to transport through pipelines and processing, uses less energy and therefore emits less CO2.”

Secondly, Voith Turbo offers solutions for the emerging hydrogen economy. It takes huge amounts of energy to enable hydrogen to be used for industrial purposes. For environmental reasons, these energy sources should if possible be generated by “green electricity” and transferred for further use. “With this in mind, Voith Turbo is already offering innovative technologies that are being optimized and continuously developed depending on the application involved. The high level of flexibility in the definition of our drive components make Voith Turbo a reliable technology and innovation partner for our customers,” says Schust.

Thirdly, Voith Turbo offers technologies that can be used in industry or the energy sector to store CO2 instead of emitting it. Technologies and processes for the capture, utilization and storage of CO2 (CCUS) are being investigated across industry and are also being implemented efficiently using drive components from Voith Turbo. This applies, for example, to cement production, thermal energy generation, or some areas within the hydrogen production segment.

Fourthly, digital products and AI-based solutions are contributing to decarbonization. “With our digitalization activities as well, we are supporting our customers’ strategies on their decarbonization journey,” says Nancy Gimpel, Vice President Product Management Digitalization at Voith Turbo, expanding on the core strategies explained above. “Our focus is on improving the efficiency and reliability of our products and processes, for example to increase the efficiency of thermal power plants, make the infrastructures for the extraction of oil and gas more efficient, and thus reduce CO2 emissions,” says Gimpel.

In this context, two key topics are at the forefront: Firstly, Voith Turbo is focusing on condition monitoring with a view to predictive instead of preventive maintenance, to monitor the condition of components and optimize their energy efficiency and overall efficiency. And secondly, Voith Turbo offers AI-based solutions that enable the monitoring of entire drivetrains and facilitate predictive maintenance.

These technologies contribute towards decarbonization, for example, by supporting the transition to hydrogen as an energy source. “By means of precise analysis and optimization of processes we can make the harnessing and use of hydrogen more efficient, all the way to the safe operation of industrial systems with H2 as the energy source of the future. And through the use of cloud technologies like the Industrial Internet of Things (IIoT), and the development of prescriptive analysis methods, we can also optimize the entire production process and monitor the quality of the manufactured products. Our solutions are currently being developed as both cloud-based and on-premise services, to best meet the needs of our customers and protect their operating data,” says Gimpel.

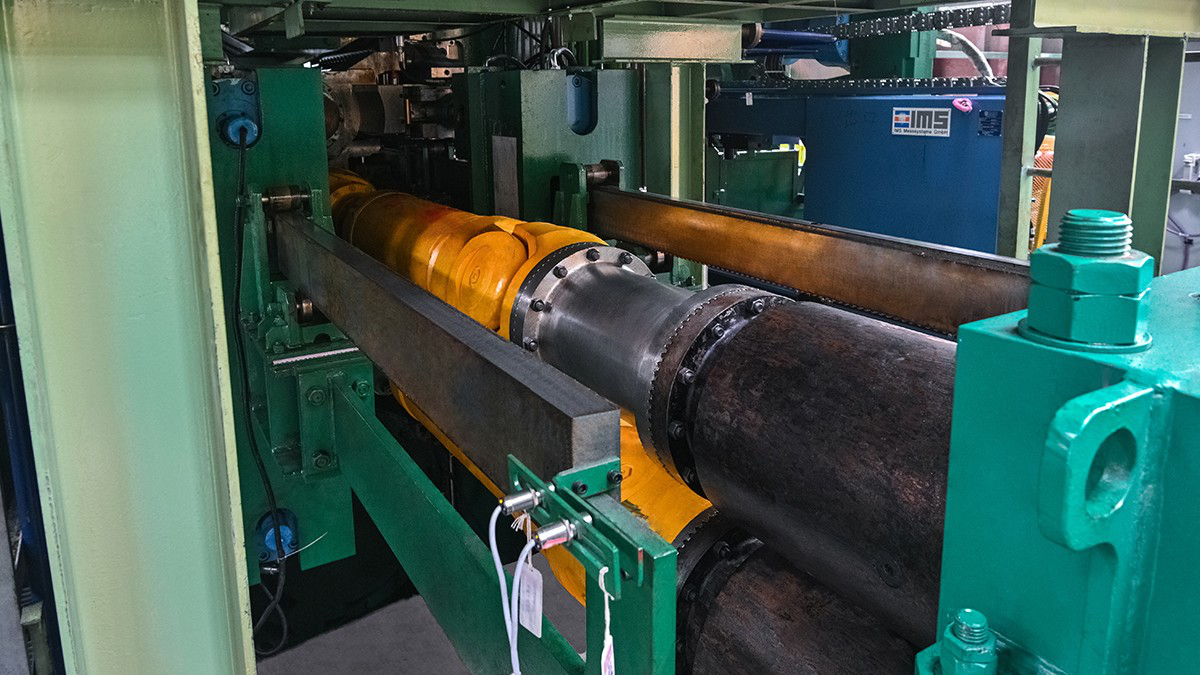

Voith Turbo offers components for oil and gas infrastructures that enable operators to improve their energy balance and reliability.

Voith Turbo offers components for oil and gas infrastructures that enable operators to improve their energy balance and reliability.

Voith Turbo technologies for zero CO2 emissions are ready for the start of energy generation with hydrogen.

Voith Turbo technologies for zero CO2 emissions are ready for the start of energy generation with hydrogen.

Storing CO2 instead of emitting it: Voith Turbo has also positioned itself successfully in the CCUS segment.

Storing CO2 instead of emitting it: Voith Turbo has also positioned itself successfully in the CCUS segment.

Digital products and AI-based solutions from Voith Turbo are also helping with decarbonization and efficiency improvements – for example through condition monitoring and predictive maintenance.

Digital products and AI-based solutions from Voith Turbo are also helping with decarbonization and efficiency improvements – for example through condition monitoring and predictive maintenance.

Compressing hydrogen efficiently with E-Packs from Voith Turbo

To transport hydrogen through pipelines over long distances, it has to be compressed more than natural gas. Rapidly rotating compressors are needed for the 90 to 120 bar needed. “With the planetary gear unit from Voith Turbo, we have a solution in our product range that we have optimized to meet the demands imposed by hydrogen,” says Tobias Weber, Senior Vice President Innovation at Voith Turbo. “Specifically, in the design as a compact E-Pack, where the gearbox is flange-mounted to the electric motor. The Voith Turbo E-Packs achieve outputs of up to 40 MW, drive speeds of up to 60,000 rpm and torques of up to 200,000 Nm. The efficiency is more than 99%,” says Felix Jahnke, Vice President Product Management Turbo Gears at Voith Turbo.

Discover the advantages of the Voith Turbo planetary gear unit

Voith Turbo is part of the “Future Program Hydrogen Baden-Wuerttemberg”

Baden-Wuerttemberg's “Future Program Hydrogen BW”, or ZPH2 for short, is designed to support the southwest German state’s goal of establishing a viable hydrogen economy in Baden-Wuerttemberg. This energy resource and its applications like fuel cells are intended to help preserve existing jobs and create new ones.

Within the scope of ZPH2, 20 projects from four technology segments are being funded. In the category “Production, storage and transport of hydrogen”, Voith Turbo is responsible for the H2Compress Project. The development team is working on a modular compression solution for hydrogen that can transport the light gas efficiently by pipeline. The H2Compress prototype will initially undergo testing on a test rig starting in 2025.

Voith Turbo is part of the “Future Program Hydrogen Baden-Wuerttemberg”

Baden-Wuerttemberg's “Future Program Hydrogen BW”, or ZPH2 for short, is designed to support the southwest German state’s goal of establishing a viable hydrogen economy in Baden-Wuerttemberg. This energy resource and its applications like fuel cells are intended to help preserve existing jobs and create new ones.

Within the scope of ZPH2, 20 projects from four technology segments are being funded. In the category “Production, storage and transport of hydrogen”, Voith Turbo is responsible for the H2Compress Project. The development team is working on a modular compression solution for hydrogen that can transport the light gas efficiently by pipeline. The H2Compress prototype will initially undergo testing on a test rig starting in 2025.

Reliable technologies for CO2 capture and storage

In the CCUS, i.e. carbon capture and storage segment, Voith Turbo has already realized some initial projects, including in the USA. In this context, integral gear units or variable speed planetary gear units from Voith Turbo play an important role. They help prepare the captured CO2 for injection and storage. As a result, the technology is making an important contribution to the decarbonization of industrial facilities.

In this new segment, operators and OEMs are also opting for products from Voith Turbo, especially due to the excellent operating experience that could be gathered in many years of safe operation in capital-intensive sub-systems in the oil and gas industry. “There’s nothing more reliable than technologies from Voith Turbo,” says Alexander Schust. “For our customers, the reliability of our products is the decisive criterion. Voith Turbo supplies drive components which as a part of system solutions make a significant contribution to economic operation and ultimately to maintaining production. A failure of these system-critical facilities would mean the loss of several million euros or dollars a day.”

Electrification of turbines offers great potential

The electrification of drive systems is another way of helping to reduce CO2. “Worldwide, there are a lot of old gas turbines in use, for example to transport oil and gas through pipelines. In this conjunction, we offer our customers electric motors that make operation much more efficient.” As well as saving CO2, the technology also offers a lower TCO.

Another solution that makes the operation of pipelines more efficient and more reliable is the Vorecon planetary gear system, as shown in this example from Saudi Arabia.