Special-purpose vessel Meteor IV: Setting the course to cutting-edge propulsion technology.

Full speed ahead: The start of construction of the Meteor IV was marked with the keel laying at the Neptune shipyard in Rostock in mid-July 2023. The special-purpose vessel has been commissioned by the German Federal Ministry of Education and Research and is set to make an important contribution to German and international marine research from 2026.

The focus will be on environmental and climate research. The results of the investigations will therefore provide new building blocks for solving current and future challenges in the scientific, social and military spheres.

Special-purpose vessel

Propulsion

2 eVSP (32X8/285)

and

1 VIT (2000-1650H)

Ideal for multifunctional and interdisciplinary tasks

Whether it is needed for national or international assignments, the 125 m long vessel is fitted with cutting-edge research facilities. These include, for example, laboratories and high-precision echo sounders as well as research winches for measurements in the deepest ocean trenches.

Voith drive systems meet the most exacting requirements

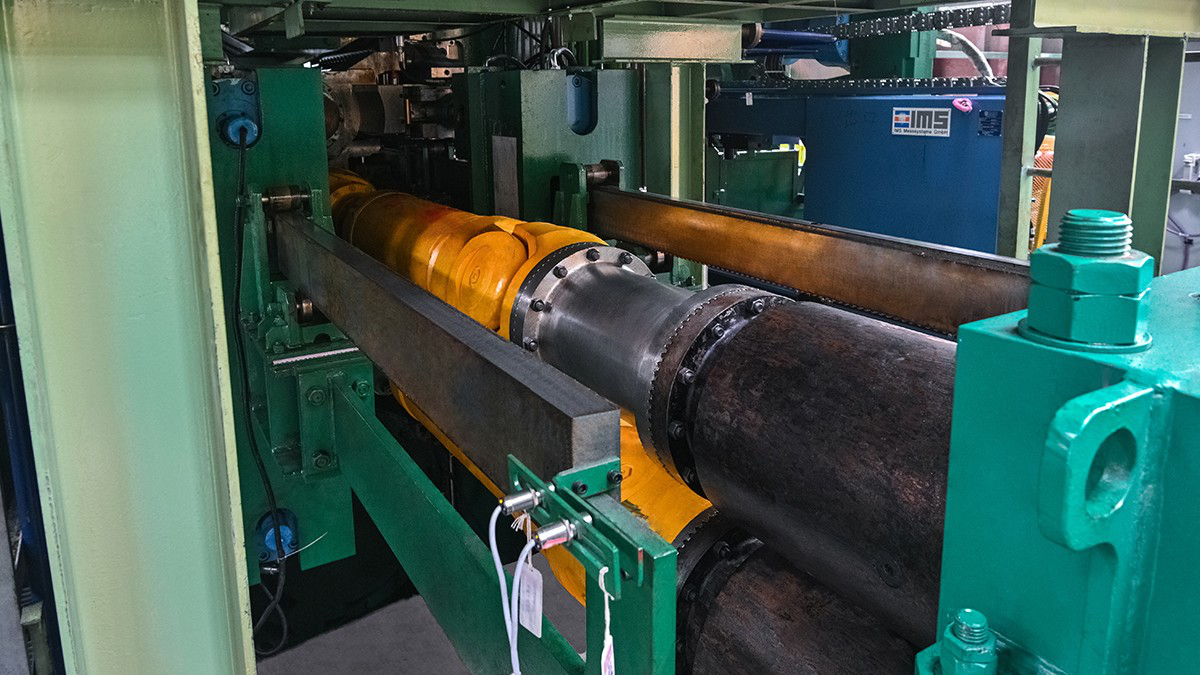

The Meteor IV also boasts high-accuracy positioning systems that allow high-precision work to be carried out. At the heart of these systems is state-of-the-art propulsion technology: Two powerful electric Voith Schneider Propellers (eVSPs 32X8/285) at the stern along with a Voith Inline Thruster (VIT 2000-1650H) and a retractable rudder propeller at the bow provide the thrust for the research vessel. The eVSP uses an integrated permanent magnet electric motor from ELIN Motors, a subsidiary of Voith Turbo.

Unbeatable advantages for military and conventional applications

The extremely fast response time of the eVSP enables a high level of performance in accurate dynamic positioning and excellent maneuverability, far superior to that of comparable propulsion concepts, even in rough waters. “This offers unbeatable advantages, especially for military uses but also for conventional applications,” explains Michael Rommel, Head of Sales & Application Management Marine at Voith.

Designed for decades of reliable operation

The Meteor IV is designed for a service life of 30 years at 345 days of use per year. This high load over many years was also a reason why the operator and shipyard opted for the eVSP. Because the innovative ship propulsion system offers high reliability, low wear, and low maintenance – especially since the propulsion system dispenses with a gearbox.

Excellent hydroacoustics and integrated roll stabilization

The eVSP offers yet another advantage: It has excellent hydroacoustics and generates minimal noise emissions underwater. Accordingly, it is one of the first controllable marine engines on the market to meet the especially demanding DNV SILENT-R standard. It also has an low level of vibration and includes an integrated roll stabilization system, which can reduce vessel roll. This greatly enhances passenger comfort for the maximum 71 people (36 nautical and technical crew members and 35 researchers) on board. It will also make it possible for them to work more safely when the ship is in rough waters.

First electric Voith Schneider Propeller (eVSP) with eight blades for even quieter and more efficient operation

The latest iteration of the eVSP will be used for the first time in practice in the Meteor IV. The eight blades ensure that maritime applications can operate even more quietly. The eight-bladed eVSP reduces the background exposure for marine life due to noise and/or underwater sound, which has almost doubled worldwide in the last few years – partly because of increasing shipping traffic and the engine noise from these vessels. Thanks to this noise reduction, the new eVSP is making an important contribution to protecting marine fauna.

Copyright: Federal Ministry of Education and Research, Fr. Fassmer GmbH & Co. KG, Meyer Fassmer Sezialschiffbau and Hamburgische Schiffbau-Versuchsanstalt GmbH.

Explore the electric Voith Schneider Propeller (eVSP) in 3D and Augmented Reality. Scan the QR-Code to experience the eVSP on your phone.