Sustainable T:

Today’s solutions for a sustainable future

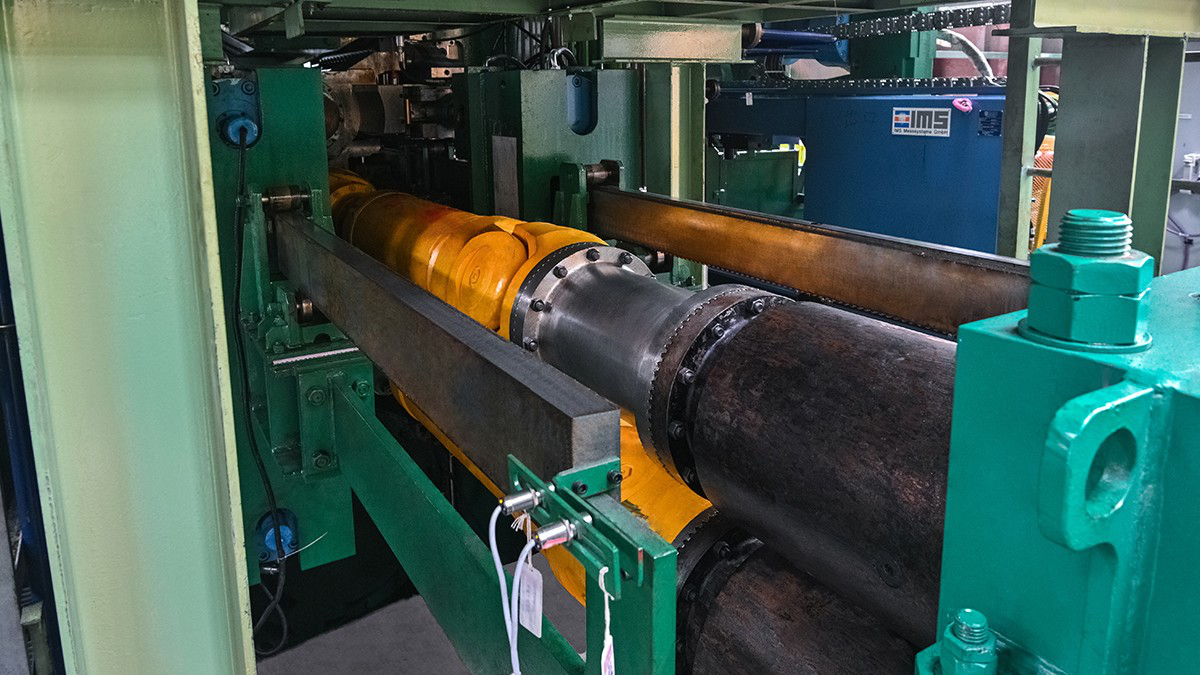

Voith fluid couplings have always stood for durability, high availability and reduced downtime, while offering a great range of applications thanks to the modular design.

With the further development of the Sustainable T concept, Voith’s hydrodynamic couplings are now taking another step forward on the road to sustainability. Voith is using pollutant-free, non-declarable materials to manufacture the couplings – and is also enabling them to be used with more sustainable operating media, even at low temperatures, where previously mineral oil was the preferred option.

Traditionally, working in mining and materials handling is one of the toughest jobs in the world. And in that respect, not much has changed, even with today’s machines providing support for these tasks in a lot of areas.

Mines always present a harsh environment and are often in remote locations. This means that adverse conditions like

- dust, dirt and water

- extreme heat or freezing cold

- special geographic locations at great height or underground

are the order of the day.

This is a real challenge for the people involved as well as for the technology that must function at these locations. Seven days a week, 24 hours a day. And this technology has to be absolutely reliable, because every shutdown costs money.

In this context, Voith’s constant-fill fluid couplings are an integral part of such technology, designed specifically for extreme requirements and tasks, including, for example:

- Ruggedness under extreme operating conditions

- Smooth startup of the equipment

- Torque limiting

- Dampening of torsional vibrations in the drivetrain

It is precisely these requirements and tasks that Voith products handle extremely reliably, thanks to their decades-long operating life.

Key application areas at a glance

Thanks to its wide range of constant-fill fluid couplings, Voith is one of the global market leaders in this field. The couplings are used successfully in numerous areas of application. For example in:

Focus on sustainable innovations

Voith’s technological leadership is no accident. “We are continually developing and refining our couplings,” says Michael Hilka, Product Manager Hydrodynamic Couplings at Voith. In this context, the issue of sustainability has increasingly been the focus of innovations in recent years.

“We are already thinking about the future today, because we are building especially durable products that are perfectly tailored to the long service lives of our customers’ equipment, in other words, 20 to 40 years,” says Hilka. “This means we pay close attention to the materials used in our components and use only environmentally compatible materials wherever possible. With this in mind, we are also conducting in-depth discussions with our suppliers and upstream suppliers.”

In the interests of increased environmental and health protection, further tightening of the regulations for processing, disposal and recycling is only a matter of time. And products that do not contain any hazardous materials also do not have to be handled or disposed of separately later. “As a result, we save our customers unnecessary concerns and unforeseen costs,” Hilka emphasizes.

A great example of how functional improvements and health and environmental protection can be implemented together is the design of the fusible plug optimized and patented by Voith. Soldering material is reduced (by up to 70% compared with competitors’ products) while the response time is improved. In addition, only soldering material without substances like lead or cadmium, which are classified as hazardous to health, are used. The broad range of the available temperature classes of fusible safety plugs also enables the coupling to be ideally tailored to the requirements of the respective application while at the same time preventing a thermal overload of the coupling and the equipment.

Use of rapidly biodegradable operating media

Another aspect of the new opportunities offered by Sustainable T is the use of more sustainable operating media. “Our constant-fill fluid couplings are designed so that customers can now also use selected operating media that are rapidly biodegradable,” explains Hilka. Voith therefore offers the option of using an alternative to the mineral oil that has been commonly used to date. The approval for these alternative media was issued following extensive testing for material compatibility.

“In this way we are enabling our couplings to be operated more sustainably without compromising quality. Our customers can continue to count on the accustomed reliability and long service life of our fluid couplings,” says Hilka.

Operates even at low temperatures

For water-powered couplings, too, the future has already begun. “The materials of the components can be selected as necessary so they can be used at temperatures down to -40°C,” explains Hilka.

For operating locations where temperatures below freezing can occur, the couplings can now also be filled with a mixture of water and selected antifreezes. Until now, operators had to resort to couplings filled with mineral oil for such applications. This is a particular advantage in the case of equipment operating in sensitive environments.

Reliable in every respect

Voith fluid couplings have always offered excellent reliability, low maintenance requirement and longevity. For example, the gentle build-up of torque ensures a smooth start-up of the equipment which in turn protects its components. During operation, the couplings dampen any torsional vibrations that occur, which also helps protect drive components.

The hydrodynamic principle allows wear-free transmission of power, which minimizes the maintenance effort and results in above-average longevity. “With Sustainable T, we have refined our hydrodynamic couplings so that they are blazing a trail not just in respect of function, wear and operating life but also when it comes to sustainability,” confirms Hilka.

Always one step ahead

The further development of the Sustainable T concept fits seamlessly into the long list of innovations that have already convinced numerous customers of Voith Turbo couplings. “We don’t regard industrial sustainability simply as a trendy buzzword,” Hilka emphasizes. “We are working and carrying out research resolutely to meet our self-imposed responsibility in every respect, both inside and outside the company.”

In this context, the focus is just as much on aspects of occupational, environmental and health protection as on promoting innovation. “This underpins the future viability of our customers and protects the future of our environment by providing increasingly greater recyclability and environmental compatibility and using materials that do not harm it,” says Hilka, summing up. “This means that we, and our customers, are always one step ahead of the competition.”