TurboBelt TPXL & DriveControl

for non-stop conveyor efficiency.

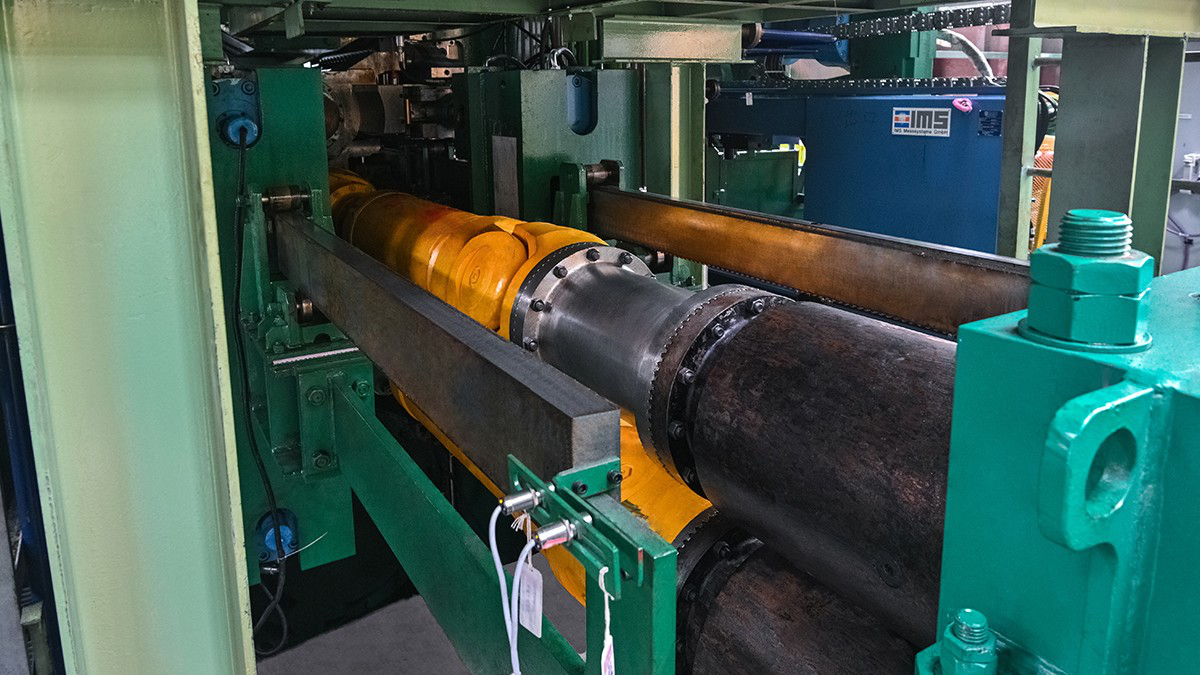

The extremely robust and efficient hydrodynamic TurboBelt TPXL coupling is intelligently controlled by the TurboBelt DriveControl – and enables mining companies to operate their conveyor systems efficiently.

Efficient coupling intelligently controlled

They have proven effective many times over when used with belt conveyors in the mining sector: Thanks to their precise control of torque, TurboBelt TPXL fill-controlled fluid couplings from Voith Turbo extend the service life of belt conveyors and ensure a continuous production process.

Strictly speaking, however, the coupling does not control itself. This is the job of the smart control system, the TurboBelt DriveControl. This combination makes the operation of a belt conveyor extremely efficient. Both components are part of the TurboBelt family, which includes other products. Voith Turbo developed all these products with the same goal in mind: To make mining cost-efficient and future-proof.

Cost-benefit analysis before award of order

Thanks to the intelligent TurboBelt DriveControl system, Voith Turbo’s experts are able to simulate in advance how a conveyor system will perform if it integrates TurboBelt components. They can predict how much energy can be saved by using one or several TurboBelt TPXL couplings, how to choose the right servicing intervals, and what percentage of the TCO (total cost of ownership) operators can save.

The digital simulation by Voith Turbo’s product management team also guarantees mining companies precious availability. Firstly, because Voith Turbo supplies its hydrodynamic couplings ex works already optimally pre-configured with all all parameters for the specific application, ensuring a speedy commissioning process. And secondly, due to the fact that the fill-controlled couplings from Voith Turbo are extremely reliable.

“Operators are interested above all in availability. They want the equipment to work, require little maintenance, and if possible, never suffer an unscheduled shutdown. Our TurboBelt satisfies these requirements to a high degree,” says Sebastian Steck, Vice President Product Management Hydrodynamic Couplings at Voith Turbo. “Reliability is what sets our products and solutions apart. Our fill-controlled fluid couplings, for example, easily cope with cold and heat. They are also immune to sand, dirt and dust. They simply keep going. And they also lead the field for robustness and durability. A combination of sophisticated hydrodynamics and intelligent controls is what makes our drive components so strong. A Voith fluid coupling is not easily thrown off course.”

Material-friendly and energy efficient: The hydrodynamic TurboBelt TPXL coupling also optimizes the sensitive start-up characteristics.

Continuous process optimization – remotely and on-site

“We continue to support our customers even after the first successful belt start-ups. Via a VPN tunnel to the TurboBelt DriveControl, we proactively monitor the process data on a regular basis from Heidenheim. In the event of deviations from set and actual values, we approach the operator and work together to resolve any imbalance occurring in the conveyor belt systems directly and uncomplicatedly, providing support on site if necessary. In this way, we are helping to improve productivity and efficiency in mining operations in general,” says Dr. Manfred Ziegler, Head of Belt Conveyor Technology at Voith Turbo.

Because the data recorded often reveal more than just the condition of the Voith Turbo components: As well as information on the performance of the coupling, the experienced mining experts at our headquarters in Heidenheim can draw further conclusions from the data and share them with their customers. “Thanks to the combination of coupling and drive control unit we can observe the overall behavior of the system. For operators this means more transparency. For example, they can bring forward a maintenance interval and thus prevent a shutdown,” says Dr. Manfred Ziegler. “All that we need in addition for this process optimization is the loading signal, however, this is available at the plant.”

TurboBelt is helping to future-proof belt conveyor systems

This contribution to process optimization is especially relevant because the transport distances in mining are becoming longer and longer, while electricity prices are going up (not to mention fuel prices). Energy consumption is therefore becoming increasingly important. Alongside high availability, this is one of the key advantages of the TurboBelt product range. “Every belt system is unique. So it is important for individual components like the coupling to be able to adapt to the circumstances on site and other technical infrastructure. With the TurboBelt DriveControl we have found the perfect response. It makes our fill-controlled couplings intelligent and belt conveyors more efficient.”

The TurboBelt TPXL product family at a glance

The fill-controlled fluid coupling TurboBelt TPXL was specially developed for belt conveyors and improves their productivity. It can be commissioned quickly and easily, integrates efficient functions, and can also operate in hazardous areas and potentially explosive environments. Voith Turbo offers the following model variants:

TurboBelt 315 TPXL

Designed for a drive power of 315 kW at 1,500 rpm

TurboBelt 500 TPXL

Designed for a drive power of 500 kW at 1,500 rpm

TurboBelt 800 TPXL

Designed for a drive power of 800 kW at 1,500 rpm

TurboBelt 1250 TPXL

Designed for a drive power of 1,250 kW at 1,500 rpm

TurboBelt 2500 TPXL

Designed for a drive power of 2,500 kW at 1,500 rpm

Standout features of TurboBelt DriveControl

The TurboBelt DriveControl digitally controls up to 8 TurboBelt TPXL couplings and optimally adapts the performance of belt systems to any operating condition.

Intelligent control

- Automatic and precisely controlled start-up process of belt conveyor

- Intelligent fill control to protect power network

- Transfer of operating conditions to control room

- Parameters adjustable on site

- Highly efficient drive solution

Simple integration

- Complete control logic for start-up of belt conveyor pre-installed

- Controller pre-configured with parameters on delivery

- All sensors connected to frequency inverter

- Main communication via various bus protocols

- Device configuration file (EDS) provided

Modern safety functions

- Hot standby mode for separation (disconnection) of drive and driven sides

- Deactivation of one or several drives to avoid downtimes and offer more flexibility

- Protection of power network thanks to load distribution

- Heavy-load start possible

Remote service

- Remote support via secure VPN (Ethernet or GSM supported)

- Worldwide commissioning, worldwide operating support by Voith Turbo

- System integration into existing infrastructure

Compact solution

- Designed to fit perfectly into drivetrain

- Coupling height adapted to motor and gear unit

- Suitable for hazardous and potentially explosive areas