Wrightbus and Voith:

Strong partners since 2007.

Around five years ago, Voith launched the VEDS (Voith Electrical Drive System) as a ground-breaking solution for public transport vehicles. Today, numerous manufacturers have already equipped their new electric vehicles with the VEDS. One such example is the long-established company Wrightbus based in Ballymena, Northern Ireland, which has enjoyed a strong partnership with Voith since 2007.

Since its inception in 1946, the pioneering solutions from Wrightbus have made it one of the transport industry’s innovation leaders, repeatedly setting new benchmarks for quality, safety and design. The solid partnership with Voith has been characterized primarily by the following five attributes:

Time-tested excellence Continuous development Technical expertise Personal service Maximum efficiency

This is best evidenced by the joint development of the two battery-electric bus models Kite Electroliner and StreetDeck Electroliner, whose excellent performance has already been tested independently – with groundbreaking results and best-in-class efficiency.

In 2023, both models were certified as zero-emission buses (ZEB) by the non-profit Zemo Partnership. In this conjunction, the GB Kite Electroliner was named the most efficient battery-electric single deck bus in the UK. Moreover, the StreetDeck Electroliner has even set a world record as the most efficient double-decker battery-electric bus in the world.

Voith Electrical Drive Systems (VEDS):

The advantages

Two bus models, one result:

Best-in-class efficiency

Wrightbus StreetDeck

Electroliner – 340 kWh

Wrightbus Kite

Electroliner – 340 kWh

Greenhouse gas savings:

The foundation for this amazing success is that both buses are powered by the innovative VEDS, which combines a water-cooled permanent magnet motor with inverter and control software. Other auxiliary components are available as options.

Thanks to the integrated system approach of the VEDS, all system components are perfectly matched to one another from the very outset. In the case of Wrightbus, the measured average energy consumption enables efficient greenhouse gas savings of 83 to 86% compared with a typical EURO VI diesel model, depending on bus model.

Three questions to Robert Best,

Director of Engineering at Wrightbus

What do you think are the key characteristics of the longstanding partnership between Wrightbus and Voith?

The engineering teams of both partners have worked very closely together from the very beginning. As a result, our expertise has simply doubled within a very short time. One of the outcomes of this is that two jointly developed battery-electric bus models are now the most efficient vehicles that have been put through their paces in an official testing procedure. And we are justifiably very proud of this.

How have your customers responded to this remarkable success?

Overall, our customers are highly satisfied with our battery-electric product. This is reflected among other things by the fact that we already have a full production schedule for the next few quarters. Currently, there are more than 300 buses with VEDS in operation – and for this year we have planned to fit more than 1,000 vehicles with the Voith electrical drive system.

Apart from best-in-class efficiency, what is the most important advantage of the VEDS compared with similar competing products?

Without a doubt, it’s the fact that the VEDS can be integrated seamlessly into the other systems in our vehicles. However, ultimately this is no great surprise, because Voith designed the VEDS as an ultra-modern plug-and-play solution. There are just a few interfaces – for ease of implementation – to switch the bus industry to zero emissions as quickly as possible.

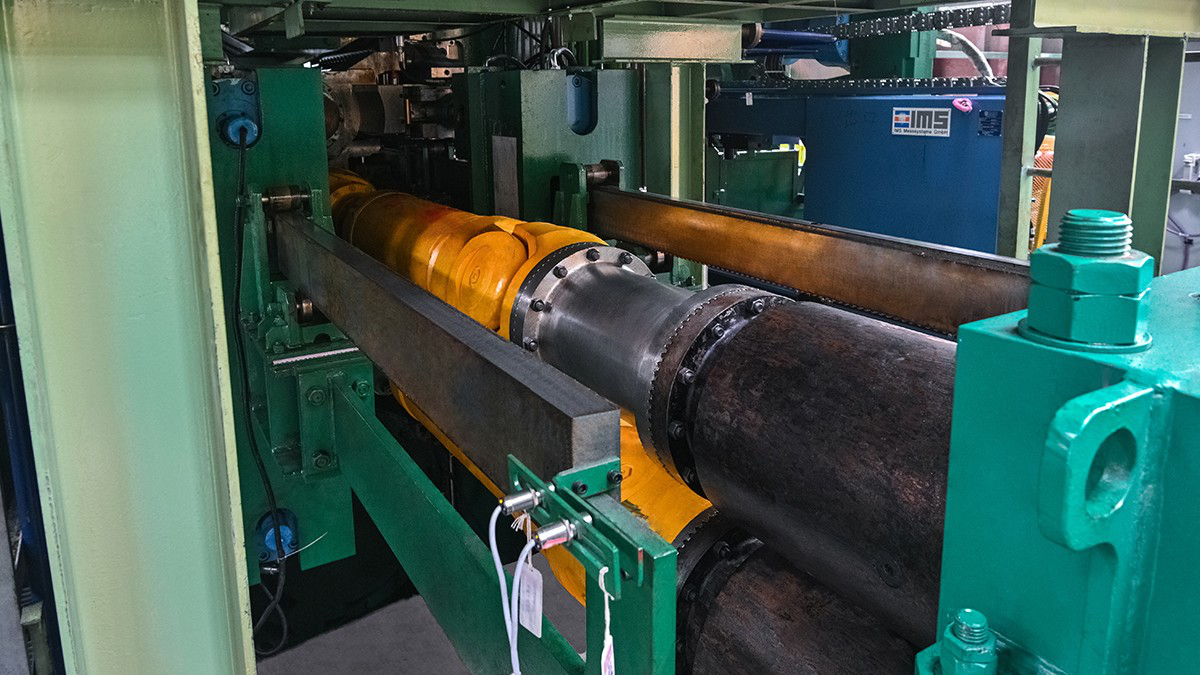

System changeover - with maximum safety ensured through a complete e-drivetrain solution from a single source

The Voith Electrical Drive System (VEDS) is an electric direct drive system for OEM independent city bus (solo, double deck, school, and articulated buses) and coach applications with both battery-electric and fuel cell electric power sources. It combines a water-cooled permanent magnet motor with an inverter and control software; further auxiliary components are optionally possible. With the integrated system approach of the VEDS, all system components are perfectly aligned with each other. It begins with hardware components such as electric motors, traction inverters and high-voltage distribution systems, and extends to software components such as drive control and energy management.

As a result, the drive system provides a low-weight solution with its compact design, enabling a lower energy consumption during operation and a range increase. Performance is another key factor. With a torque of 3,100 Nm and a power of 310 kW (continuous power) the heavy-duty (HD) direct drive electric motor is suitable for solo buses, heavy articulated or double-deck buses. The medium duty (MD) electric motor shows a torque of 2,850 Nm with an output of 230 kW (continuous power), suitable for medium-duty buses.

Two motor variants possible: HD or MD E-Motor

First e-drive system with functional safety conformity (ISO 26262) and isolation class IP6K9K

Modular approach with various power levels and high flexibility in the direction of interfaces within VEDS

With DCDC converter suitable for fuel cell application

Customer support over the whole product life cycle

Best in class efficiency officially approved by independent UK authority