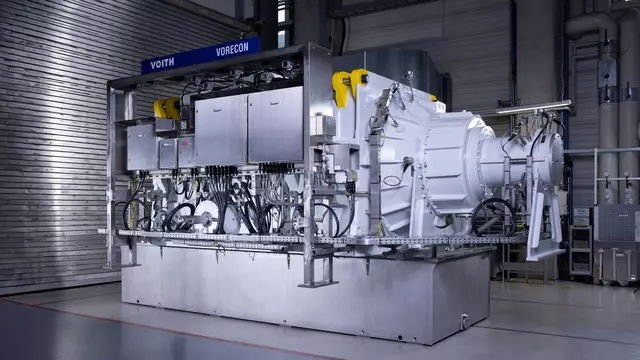

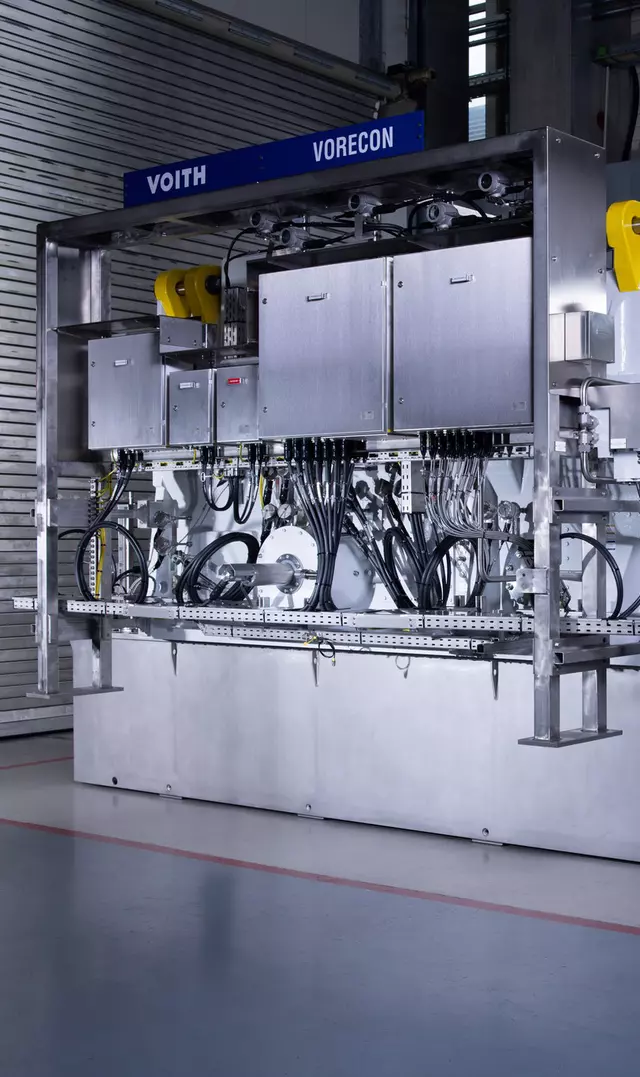

Vorecon from Voith Turbo improves the efficiency of the pipeline operation.

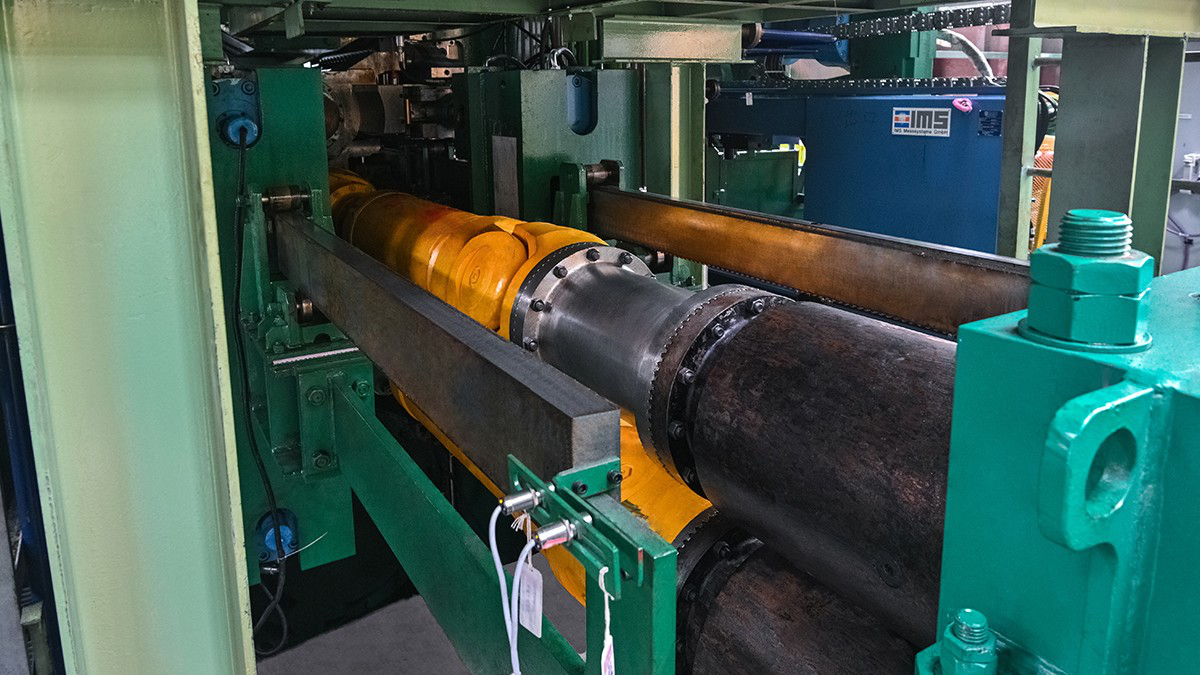

Critical infrastructure is subject to stringent safety and reliability requirements worldwide. Especially when it comes to facilities that are important over and beyond national boundaries. The Saudi Aramco East–West Pipeline stretching over 1200 km is one example of this. It links the oil fields in the east of the country with the refineries and the Yanbu commercial port on the Red Sea in the western part of Saudi Arabia. It was put into operation in the 1980s and is essential for the global economy. The operator took advantage of a necessary upgrade to improve the energy efficiency and reliability – and selected Vorecon units from Voith Turbo to operate in two of the eleven pump stations along the pipeline for a significant increase in efficiency. The variable-speed planetary gears combine numerous advantages, the major ones being extreme longevity and low maintenance requirements.

Efficient control of pumps and compressors:

Highlights of the Vorecon variable-speed planetary gear system

RWE 13.5 FC 9

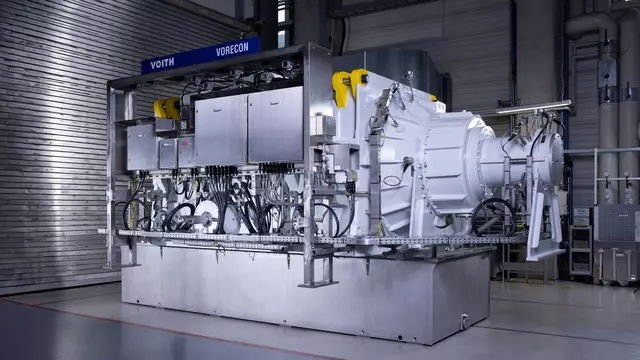

Voith Turbo’s energy-efficient technology convinces global market leader

“Saudi Aramco is state-owned and one of the largest oil and gas companies in the world. In addition to producing energy sources, Saudi Aramco also makes chemical products. We at Voith Turbo are proud to have been a technology supplier to Saudi Aramco since the 1960s. Our state-of-the-art drive technologies support the reliable operation of several energy infrastructures systems and improve efficiency,” says Hassan Abusanah, Project Development Manager at Voith Turbo. “With the Vorecon, we can optimally meet customer requirements. The technology is characterized by a high efficiency and an extremely high reliability. And through the electrification of pipelines with Vorecon, the CO2 emissions are also lowered.”

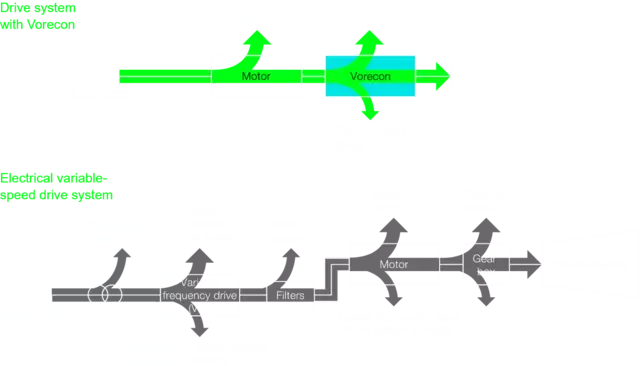

The reason: The Vorecon is a hydrodynamic variable-speed planetary gear. With it, customers can control the speed of driven machines and units. The technology combines reliable mechanical components with hydrodynamic power transmission. As a result, it has a service life of many decades. Generally, its life cycle is three times longer than that of variable frequency drives. The Vorecon’s mean time between failures (MTBF) is an incredible 48 years. This is one of the reasons why the units are also miles ahead when it comes to the total cost of ownership (TCO).

Attractive Total Cost of Ownership (TCO):

Service life comparison

Attractive Total Cost of Ownership (TCO):

Overall efficiency comparison

Reliable operation even under extreme climatic conditions

In addition, controlling the speed of pumps, compressors, or fans saves a lot of energy. With their characteristic reliability added to that, Vorecon units provide the basis for high productivity and energy-efficient operation of pipelines and other facilities. All over the world, even in the extreme environmental conditions that prevail in Saudi Arabia. The blistering heat, extreme temperature differences between day and night, and dreaded sandstorms will hardly have an effect on the robust units over the long term.

Background: The East-West pipeline

The East–West pipeline is part of Saudi Arabia’s critical energy infrastructure. The operator, Saudi Aramco, transfer crude oil from the extraction facilities in the east of the kingdom to the refineries and export terminals in the west through 1200 km of pipeline.

An upgrade was to be performed to make operation more energy-efficient and contribute to lowering the CO2 emissions. There are 11 pump stations along the East–West Pipeline distributed over a remote and inaccessible desert region. They were previously driven by gas turbines.

As part of its decarbonization strategy, Saudi Aramco decided to convert to a more efficient and reliable technology for driving the crude oil pumps, initially at two of the stations.