One for All: Our complete service for trains, available worldwide.

Regardless of which OEM they are from, trains generally contain components from many different manufacturers. Naturally, rail fleet operators want a reliable service partner that can nevertheless offer all maintenance and repairs from a single source. This is why Voith Turbo is systematically expanding its service to cover all manufacturer brands. In doing so, the company benefits from its comprehensive expertise in drive technology and its close-knit global service network.

Working to ensure train availability

Even the most reliable technology does not always work smoothly. At some point, every bogie, every locomotive and every train has to go to the workshop. Whether the work involves a routine inspection, the replacement of wear parts or the repair of damage, the operator’s objective is clear from the outset: The vehicles need to be back in service as quickly as possible – and then function without problems until the next service is due. Because to generate revenue, trains need to be available.

“Our customers generally have a variety of products from different manufacturers installed in their vehicles,” says Andreas Kelterer, Director Global All Brands Products at Voith Turbo. “Nevertheless, operators would prefer to have a single service provider to take care of the entire vehicle, regardless of who manufactured the individual components.” The service for all manufacturer brands that Voith Turbo is systematically developing is the company’s response to this customer requirement. Because the greater the number of different service providers that need to look after a vehicle, the longer the costly downtimes.

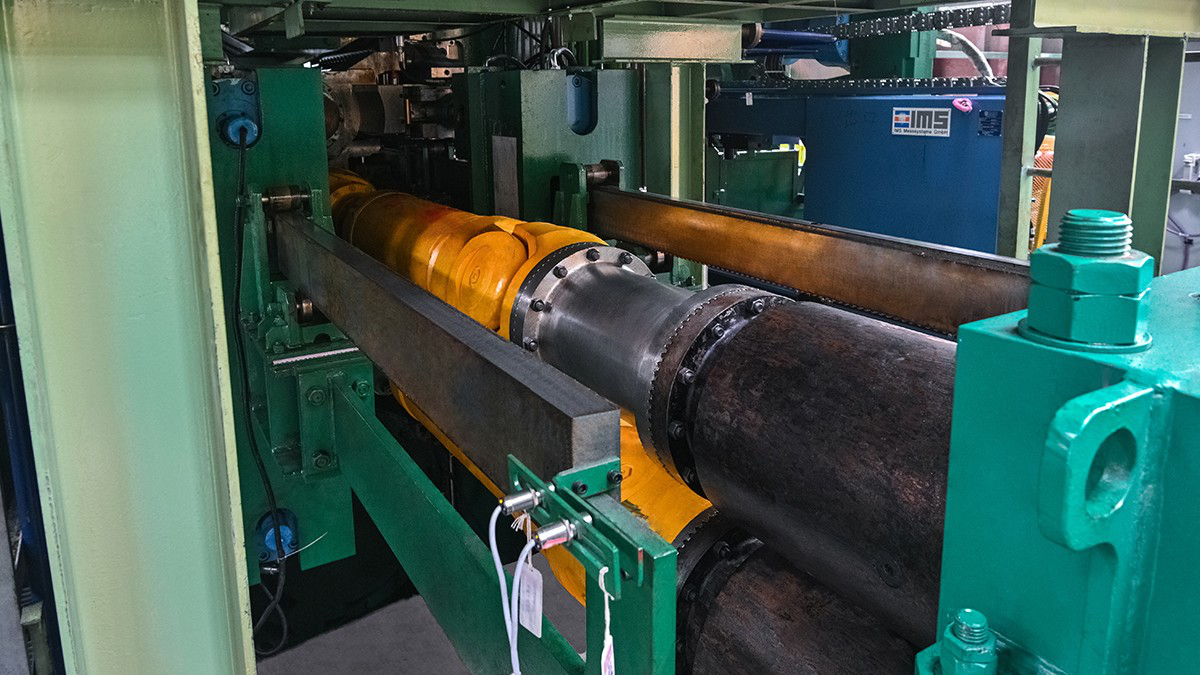

Service for trains and components of all manufacturers: Examples from all over the world

Customer proximity and efficiency thanks to extensive global service network

Customers all over the world appreciate the good service quality and comprehensive technical expertise of Voith Turbo. “Voith has been working for years with many of its customers, so it’s logical that they do not want to just look for a new partner, simply because there is no Voith technology in their vehicles,” says Mario Gies, Vice President Service for All Brands at Voith Turbo. The concept also benefits from Voith’s comprehensive global service network, which simplifies work at customer sites and reduces costs, for example because the service team only needs to travel a short distance.

“Our extensive service network is an important foundation that allows us to offer our service for all manufacturer brands worldwide,” says Mario Gies. This network also makes it easier to protect supply chains, an aspect that has become much more important in recent years. Currently, for example, the company has contracts with companies in France, Germany, and China, where Voith Turbo Service is overhauling all brands of couplers for Line 9 of the Shanghai Metro. An important by-product of this manufacturer-agnostic service concept is that components can also be upgraded to meet new requirements, e.g. by installing low-emission drive packages.

And Voith Turbo is not limiting its solutions to rail vehicles alone. For some time now, the team has been working on service products for the commercial vehicle segment. “We are planning to further expand our capabilities in this area,” says Mario Gies,

who already has some new ideas in mind for this purpose.

Tackling complex service issues in a spirit of partnership

“When we were preparing for a general overhaul of our fleet in 2018, we determined that the servicing of the couplers was going to be extremely difficult and costly,” says Rafael Mana, workshop coordinator at MetrôRio, explaining how the contract with Voith Turbo came about. Most of MetrôRio’s subway trains had been supplied by Chinese manufacturer CRRC, whose specialists would have had to travel specially to Brazil, “which would have led to high costs and long servicing times.” So Mana’s team started to explore alternatives. Among some of the people they approached were colleagues from São Paulo, who reported on their positive experiences with Voith.

Very soon, Voith Turbo Brazil and MetrôRio were holding intensive discussions about the overhaul of the couplers. “From the very outset we were convinced of Voith’s ability to meet our requirements. Not only does Voith Turbo have a skilled service team in Brazil, but it is a global company with a sound reputation in the rail coupler segment,” adds Glauco Bernardo, Rail Vehicle Manager at MetrôRio. Voith’s first step was to put together a kit with all necessary spare parts. The team then overhauled the couplers for a total of 64 trains. As part of the collaboration, Voith Turbo also conducted theoretical and practical training for MetrôRio’s technical team, paving the way for a long-term partnership.