Electrifying buses with VEDS: Farewell fuel tank, hello battery.

Emission-free public transport without the long delivery times for new vehicles: The Voith Electrical Drive System can be retrofitted to existing diesel buses.

High investment costs and long delivery times are slowing down the shift to sustainable public transport. But there is another way.

The mobility transition is presenting a major challenge to municipal operators of large bus fleets. Because the investment in new electric buses is costly and the delivery times are long. At the same time, public transport that is emission-free at least locally is a plan that an increasing number of municipalities worldwide have been implementing for a long time now. With its VEDS, Voith Turbo offers a route out of this trade-off. The acronym stands for Voith Electric Drive System, which offers transport companies the option of electrifying their existing conventionally powered vehicle fleet so as to transition quickly and efficiently to electric mobility.

Here you can go directly to the interview with Michael Dalhof, Managing Director of Stadtbus Schwäbisch Hall GmbH

Already, towns and cities with 100,000 to 200,000 inhabitants often have more than 100 buses operating in their public transport networks. In view of the price tag of more than half a million euros for a new vehicle, it is clear that there is a need for additional options for the electrification of these kinds of fleets. Moreover, the mobility revolution cannot be mastered with money alone. In some cases, the delivery times for popular bus models are 18 months or more.

E-retrofit pays dividends

The good news is that new vehicles are not the only way to electrify public transport services that have previously been powered by fossil fuels. To speed up the switch to more sustainable transport concepts, the e-retrofit is an attractive option. It consists of replacing the combustion engine in diesel buses by an electric drive system. In practice, it has emerged that the retrofit does not interfere too much with operations. Because transport companies can use buses from their entire fleet with almost no downtime, and pay only for the new electric components.

And that pays dividends. On average, a public transport bus will have reached around half its total service life after six to eight years. Thanks to the retrofit, operators gain a breathing space of several years before they have to invest in a new e-bus. In the meantime, they meet the statutory requirements of the stringent Euro 7 emission standard and in many cases benefit from national and regional government subsidy schemes.

Simple integration of electric technology

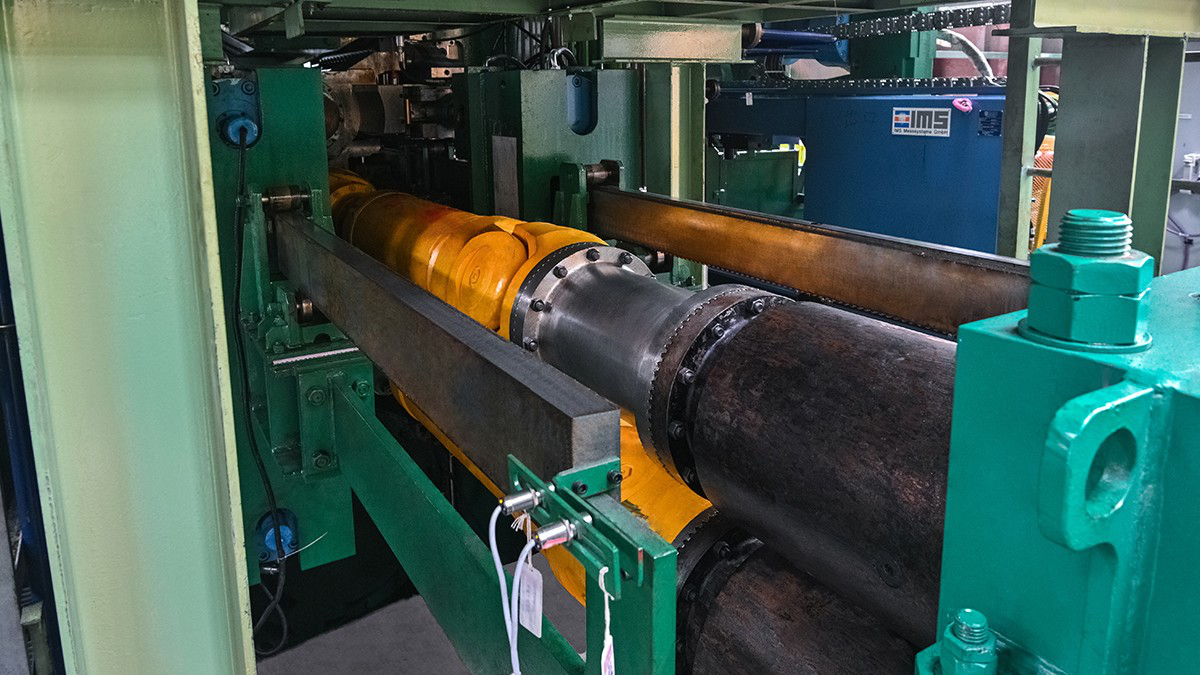

From a technical perspective, the retrofit is surprisingly simple. “In modern diesel buses there is almost always sufficient room for drive and storage system,” says Jürgen Berger, Senior Project Manager R&D E-Mobility at Voith Turbo. Along with his team, he developed and tested the Voith Electric Drive System (VEDS) – a pioneering electric drive system for public transport – and successfully launched it on the market. Numerous OEMs of public transit buses are already using the VEDS in new vehicles.

A key to the simple integration of the VEDS into existing models is its compact design. This is what makes the retrofitting of conventionally powered buses – i.e. with diesel, hybrid or gas drives – possible in the first place. “The motor needs around the same space as a conventional transmission. Most of the other components can be housed in the engine compartment. Batteries, for example, can be installed where the combustion engine once was,” says Jürgen Berger.

Modifications to the chassis are not necessary; only in low-floor buses do the seats have to be raised slightly.

VEDS mobilizes

410 kW peak power and

310 kW continuous output.

Crucially: “Following the VEDS retrofit, the bus has room for just as many passengers as before,” says Thomas Sautter, Senior Vice President Sales DACH at Voith Turbo. The efficient electric motor from Voith Turbo ensures that the passengers can be transported quickly and reliably. This powerhouse has a peak output of 410 kW, with a continuous output of 310 kW. “This is enough to move even double deckers and heavy articulated buses without problems,” says Thomas Sautter.

Traditionally, one of the pain points of electric mobility is the charging process. Buses equipped with VEDS rely on the widely used CCS2 connector. “This means that VEDS buses and commercial vehicles can charge their battery in around an hour at DC fast charging stations,” says Jürgen Berger. When recharging at AC charging stations, the process takes four to five hours from 0 to 100%. For use in public transit, however, this interval is often sufficient, so that the investment in charging infrastructure is kept within reasonable limits.

Enormous expertise on board

Voith is offering its retrofit option in collaboration with Orten Electric Trucks, and is the exclusive supplier of the drive system. In recent years, Orten has acquired extensive expertise in electric mobility for commercial vehicles, especially in retrofitting. As one of the first mobility service providers, Transdev ordered several VEDS for existing vehicles operating in scheduled services in the south-west German towns of Schwäbisch Hall and Heidenheim.

Transdev operates the largest electric bus fleet in Europe. What is the company’s experience with these vehicles in scheduled services? By 2025, Transdev will operate more than 5,000 electric buses in Europe. Currently we have around 2,000 e-buses at over 100 locations. We now operate an industrial e-bus service. This term reflects our aspiration to offer scheduled services that are not inferior in any way to public transport powered by fossil fuel systems.

Why is Transdev now focusing on retrofitting existing vehicles? In Germany alone, Transdev operates more than 3,000 buses. Some of these will certainly be retired over the maximum possible technical service life, and alternatives will need to be found for the others. In the case of existing vehicles that have been converted (D2E), we are still in the advanced trial phase. It remains to be seen how the market will accept these D2E buses.

How will the converted vehicles be used? These vehicles will also be used alongside new vehicles in industrial e-bus traffic, i.e, in scheduled services and as a supplement during peak periods.

At Transdev, does e-mobility mean battery-electric drive systems or does the fuel cell also play a role in your planning? Both technologies have different applications. We envisage the e-bus for use in urban traffic, whereas the FCEV bus is certainly the better option for intercity and coach travel. This is why we are already following developments and implementing pilot projects.