One of the world’s leading suppliers of hydraulic machines

For more than 150 years, Voith Hydro has developed, built and installed hydraulic machines for the development of hydropower.

During this time, Voith Hydro has contributed significantly to the advancement of many types of hydropower turbines. Thousands of installed hydropower plants worldwide were provided with Voith Hydro turbines. The foundation of Voith Hydro's expertise is the accumulation of equipment operating results over time.

Our product portfolio

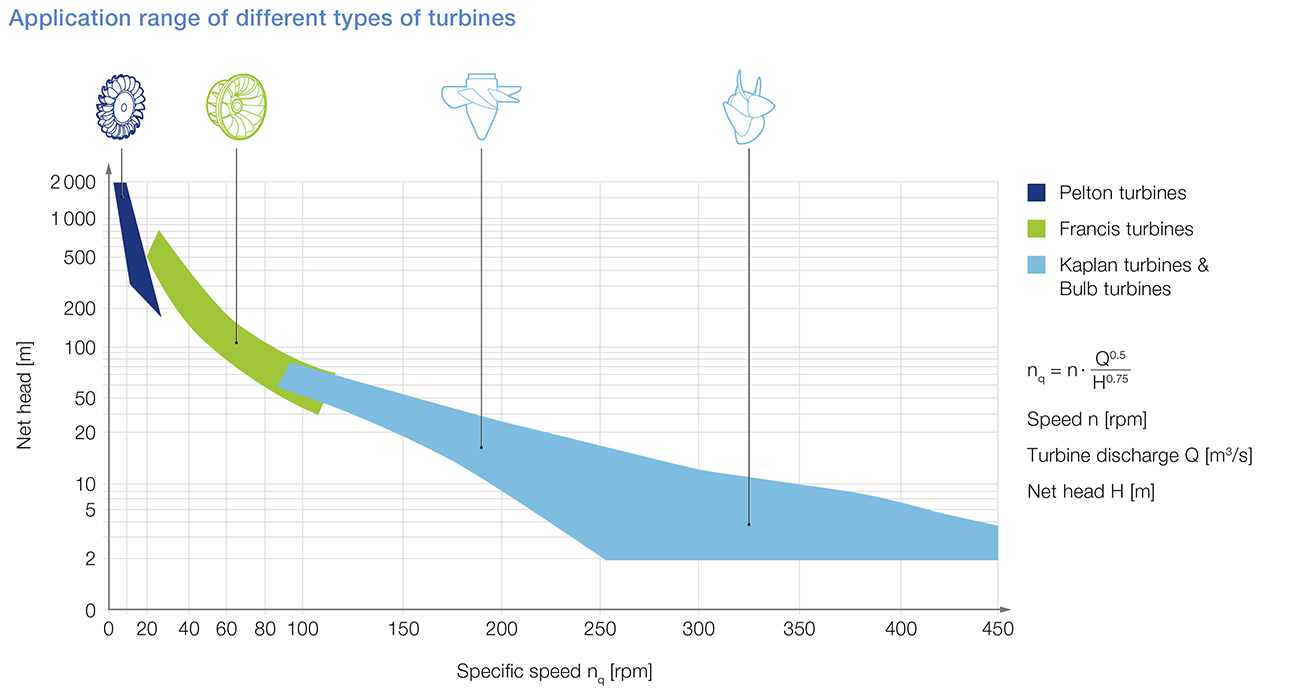

Francis turbines

From the beginning, Francis turbine development has always been synonymous with Voith. In 1873 Voith installed the first Francis turbine and had improved the original design by applying movable wicket gates for the control of the turbine.

Thanks to continuous optimization over the years based on the latest hydrodynamic research, Voith developed the world’s largest and most powerful Francis turbines. Because of their wide range of applications, well over half the turbines manufactured by Voith are of the Francis type. We have successfully commissioned Francis turbines with runner diameters of up to 9 m and with outputs of up to 800 MW.

Francis turbines are used primarily for medium heads up to 600 m and large flows. Their special hydraulic characteristics enable relatively high-speed compact units, right up to the highest power outputs.

Technical data:

| Power | up to 850 MW |

| Head | up to 600 m |

| Runner size | up to 9 m |

Kaplan turbines

In 1913, the company was the first to recognize the importance of Victor Kaplan’s invention and, in partnership with him, developmental tests were carried out. Since then, thousands of Kaplan turbines have left our workshops, among them the most powerful and largest in the world with an output of up to 200 MW and runner diameters of up to 10.5 m.

Our stepped program offers the best economical solution for any requirement. Large custom-built Kaplan turbines for high output ranges are Voith’s specialty. Custom Kaplan turbines are used primarily for lower heads up to 50 m and larger flows.

Technical data:

| Power | up to 350 MW |

| Head | up to 90 m |

| Runner size | up to 12 m |

Pelton turbines

The flow simulation of Pelton turbines is by far the most complex and difficult of all hydraulic turbo-machinery simulations. Pelton turbines involve a number of special flow characteristics which are extremely difficult to simulate. The jet-bucket-interaction is fully transient and depends on the moving geometry of the buckets. Even more challenging is the multiphase system of air and water that governs the formation of the free jet and the flow through the buckets. In the past, developing a flow simulation that would allow a realistic analysis of these phenomena seemed to be a task not to be solvable.

Voith’s numerical development group has finally overcome these major problems in simulating the bucket flow typical for the Pelton hydraulic. Simulation results and experimental data have shown a remarkable congruence. Today, designers have new insights into complex bucket flow phenomena providing a solid foundation for the development of new bucket profiles that result in improved Pelton turbines. Among these are units with outputs up to 300 MW and runner diameters up to 5 m that we have successfully commissioned.

A broad manufacturing program offers an economical solution for any significant requirement. Large, custom-built Pelton turbines for high output ranges of up to 1 500 m are our specialty.

Technical data:

| Power | up to 300 MW |

| Head | up to 1500 m |

| Runner size | up to 5 m |

Bulb/Pit/S turbines

The hydraulic development, design and manufacture of bulb/pit turbines have been significantly influenced by Voith for decades. Specific project requirements determine which hydroelectric equipment is favorable on a case by case basis. The application of bulb and pit turbine units provides unique advantages. Their design provides good accessibility of various components and assures reliability and long service life.

Advantages:

Higher full-load efficiency and higher flow capacities of bulb and pit turbines can offer many advantages over vertical Kaplan turbines. In the overall assessment of a low head project of up to 30 m, the application of bulb/pit turbines results in higher annual energy and lower relative construction costs. We have successfully installed turbines with a runner diameter of up to 8.5 m and an output of up to 80 MW.

Technical data:

| Power | up to 80 MW |

| Head | up to 30 m |

| Runner size | up to 8.5 m |

Pump turbines

In 1937 we developed the first large pump turbine, which operated both as a turbine for energy generation and in the reverse direction as a pump. Today, nearly 200 Voith pump turbines have been installed worldwide with a combined output of over 25 000 MW. With a wide range of specific speeds, pump turbines can be installed at sites with heads up to 700 m, and with unit capacities ranging from less than 10 to 500 MW.

The company’s state-of-the-art technological level is constantly improved and includes latest developments on variable-speed technology and wide head range applications. These machines have proven extremely reliable in practical operation. In some cases this experience covers many decades. It makes no difference whether demand is for a reversible pump turbine or an optimally designed combination of turbine and pump.

Technical data:

| Power | up to 500 MW |

| Head | up to 700 m |

Voith Hydro is setting new standards with the first horizontal, six-nozzle Pelton turbine.

One particular challenge has kept Voith Hydro’s development engineers busy for more than 10 years: What if we could arrange Pelton turbines with three or more nozzles horizontally without sacrificing performance, instead of vertically, as is the norm today?

Application range and development of our turbines

Back to the roots: History of hydropower turbines

Historical key facts

- 1870: Beginning of the manufacturing of hydraulic turbines

- 1873: Construction of the first Francis turbine

- 1903: First order from the USA (Hamilton, Niagara Falls)

- 1908: Establishment of the hydraulic laboratory "Brunnenmühle"

- 1913: Support of Viktor Kaplan in developing Kaplan turbines

Shut-off valves - Voith control equipment for turbines

Voith started designing mechanical-hydraulic control equipment for water turbines as long as a century ago, because extreme adjusting forces and short closing times cannot be coped with by purely mechanical means. On long penstocks of a hydro powerplant, the high pressure end can be equipped with a Voith closure valve to shut off the water supply of the turbine. This allows turbine dewatering for inspection and maintenance without dewatering the penstock.

Environmentally-friendly hydropower products

Minimizing the impact on the environment

All forms of energy production require balancing tradeoffs with benefits. Throughout Voith Hydro’s unparalleled industrial experience spanning more than 150 years, the organization has been working to minimize the impact of hydropower on the environment. Specifically, ensuring safe fish passage has been one of Voith’s industry goals for the last 50 years, leading the company to conduct analytical and physical modeling in its laboratories. Greaseless technologies have been commonly used to maintain water quality for more than twenty years.

Developing fish passage technology to allow for direct turbine passage began in the 1990s and continues to this day. The goal for these efforts is to reach fish passage levels similar to those that existed prior to hydropower installation at a given site, while minimizing cost and efficiency loss.

Minimizing the impact on the environment

All forms of electricity production require balancing tradeoffs with benefits. Throughout Voith Hydro’s unparalleled industrial experience spanning more than 150 years, the organization has been working to minimize the impact of hydropower on the environment. Specifically, ensuring safe fish passage has been one of Voith’s industry goals since the 1990s, leading the company to conduct analytical and physical modeling in its laboratories. Greaseless technologies have been commonly used to maintain water quality for more than twenty years.

Minimum Gap Runner

Adjustable blade turbines such as Kaplan or Bulb turbines feature blades with varying pitch and are characterized by gaps at the inner and outer blade peripheries. These gaps can give rise to leakage flows, resulting in the formation of vortices. These secondary flows cause elevated water velocity, shear and rapid pressure changes and low absolute pressure levels, all of which are potentially harmful to passing fish.

To minimize the effects of gap flows on fish survival, Voith Hydro developed the Minimum Gap Runner (MGR) technology as part of the Department of Energy’s Advanced Hydropower Turbine System (AHTS) program.

The MGR blades are contoured to a fully spherical hub and periphery so that the design gap remains constant across the pitch range. In addition to the stated goal of improving fish survival, the minimal gap also has positive impacts on turbine efficiencies.

Over the past decade, MGR technology has been implemented at several large axial flow units in the field. Examples are the Grant County (Washington) Public Utility District’s Wanapum Dam, the US Army Corps of Engineers’ Bonneville Dam and American Municipal Power’s Ohio River projects.

Fish survival rates through MGR units have been documented to be in excess of 95%.

Oil-free hubs

Adjustable blade runner hubs are typically filled with pressurized oil. This oil lubricates runner blade trunnion bearings and sliding parts of the operating mechanism in the hub. However, using hub oil endangers water pollution by oil spill from the hydroelectric facility. In order to eliminate this risk, Voith Hydro has been developing and installing oil-free solutions since 1985.

Pressurized oil has been replaced by self-lubricating materials and assures not only the prevention of accidental releases of grease substances into the environment but also allows for easy maintenance, lower friction and good bearing performance without the necessity of increasing servo size.

Aerating turbine technology

Over the years, Voith Hydro has become a leader in providing aeration solutions that improve environmental compatibility through the increase of dissolved oxygen uptake downstream of hydropower facilities. These advancements address a common issue faced by hydropower producers: the need to improve water quality, specifically dissolved oxygen content, as water is discharged from existing and new hydroelectric equipment. The water in the lower reaches of many reservoirs is oxygen deficient.

Often, low pressure regions below the runner can be utilized to draw atmospheric air into the turbine during operation. These machines are referred to as auto-venting turbines (AVT) and are particularly cost-effective for injecting large quantities of air into the discharge.

Auto-venting turbine aeration generally consists of three different aeration options, including distributed, central and peripheral aeration.

The interaction between the incoming bubbles and the surrounding water drives the aeration performance by influencing the pressures at the air injection location, the resulting air flows, the dissolved oxygen uptake efficiency, and the turbine performance.

For each project, individual site characteristics, plant design, and desired operation are incorporated into in-house calculation methodologies which account for the necessary bubble modeling to optimize aeration behavior. Based on the predictions, Voith Hydro selects aeration solutions which provide the best value for the customer by maximizing uptake while minimizing the impact on turbine performance and aeration costs.

Alden turbines

One of the newest improvements to fish passage technology comes through development of an innovative runner concept by Alden Research Laboratory. The Alden Turbine features a slower rotational speed and only three blades to reduce fish mortality due to blade strike. Voith Hydro has optimized the final design and tested it at their hydraulic laboratory in York, Pennsylvania (USA).

The blade shapes are specifically designed to improve the fish passage environment through the turbines by minimizing shear, pressure change rates and minimum pressures within the water passage. Depending on the species, full-scale fish survival rates are expected to range from 98% to 100%.

Through funding made available by the DOE, EPRI and industry partners, Alden Research Laboratory collaborated with Voith Hydro to improve the performance characteristics of the conceptual turbine while maintaining or improving the fish-friendly characteristics. The partnership also focused on ensuring the turbine’s cost-effectiveness while maintaining improvements in fish survival rates.

Key benefits:

- Reduced strike probability by optimizing the number of turbine blades, wicket gates and stay vanes as well as improving the hydraulic profile of the turbine components and the rotational speed

- Optimized water passage geometries to meet specified fish passage criteria

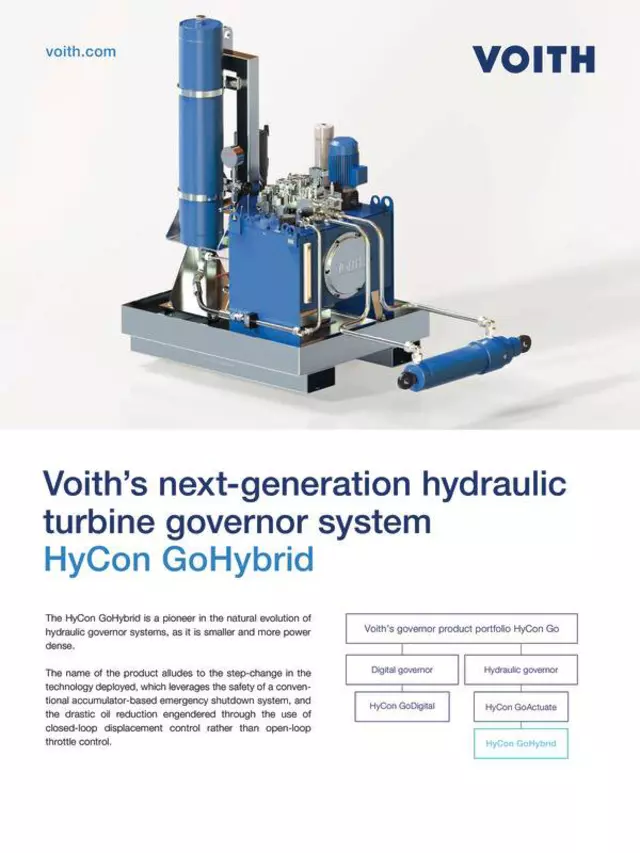

HyCon GoHybrid

The HyCon GoHybrid is a highly innovative and efficient, hydraulic power unit with a particularly compact design to enter the next-generation of governor systems. Standardized components reduce maintenance costs for operators.

The oil system’s reduced complexity lowers the required oil volume by up to 60 percent compared to conventional high-pressure units and by up to more than 90 percent when measured against low-pressure units, thus providing a more environmentally friendly solution. The HyCon GoHybrid is a state-of-the-art concept that goes beyond the common technical specifications and conventional rules.