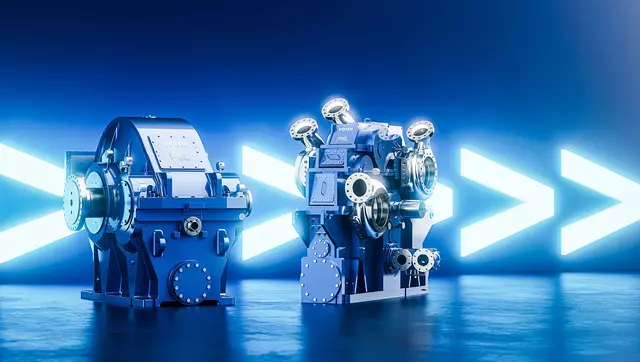

Tailor-made, efficient, and reliable

Meeting the highest demands and defining industry standards, our BHS turbo gear portfolio includes innovative products with higher speeds, more power, and safety. Learn about our services, such as short delivery times and optimized costs, and contact us for your free consultation.

Turbo gears at a glance

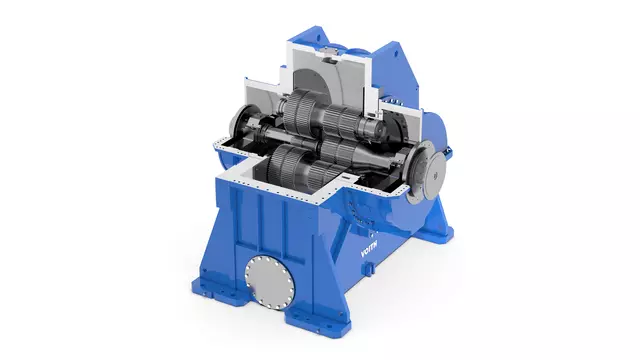

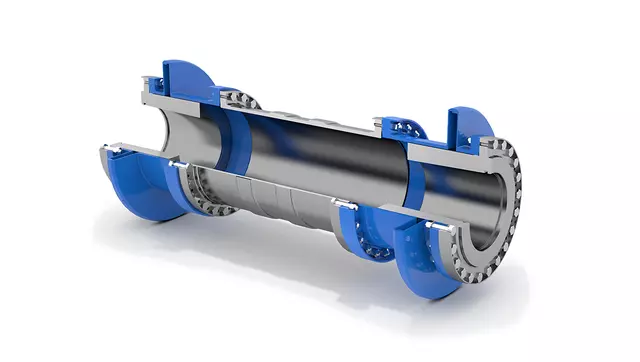

Our high-quality BHS turbo gear units and components are suitable for use in the power, oil, gas, chemical & petrochemical, and steel industries, as well as other industrial sectors.

Our Competence Center: Highest expertise for best gear unit solutions

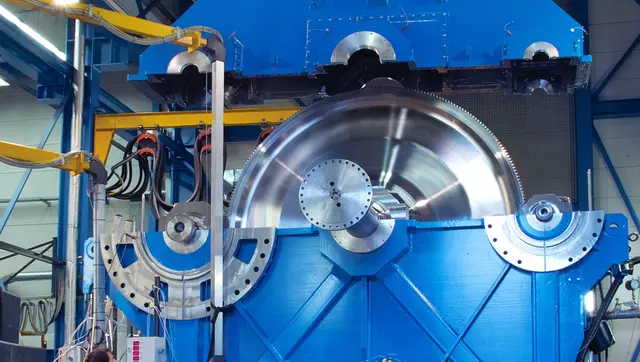

Built on over 90 years of experience, Voith BHS turbo gear units offer a Mean Time Between Failures (MTBF) of over 100 years, ensuring maximum reliability. At the Competence Center in Sonthofen, our team is constantly developing the technology further, while the Crailsheim plant serves as the central production and testing location.

Discover more about the Competence Center in our digital magazine:

Downloads

Product registration

In order to receive quick technical support in the event of service, we recommend registering your Voith product. You can scan the QR code on the product or click on the button below to register your turbo gear unit or component. Please provide us your contact details, the product name, the KVO number and optional the date of commissioning.

Voith Service

- Everything from a single source: development, design, production – and service!

- Decades of product experience as an original equipment manufacturer and service provider

- Fast and smooth cooperation and best service thanks to a worldwide network of service locations

- Long-term partnership and planning security are guaranteed due to longstanding corporate stability

Voith Turbo Newsletter

Sign up for the Voith Turbo newsletter and get exclusive insights into the world of drive technology. You'll receive regular updates on:

- Voith Turbo's latest products and solutions

- Industry trends and applications

- Upcoming events and webinars

By subscribing to our newsletter, you'll stay ahead of the curve and learn how Voith Turbo can help you optimize your operations.