Actuators & Control Systems from Voith Turbo:

Building trust through reliability.

In many plants or factories, shutdowns need to be avoided under all circumstances. For example, a shutdown in a refinery or chemical plant can easily cost the operator up to €1,000,000 a day. In the case of critical infrastructure facilities like thermal power plants, there is also the threat of serious consequences for the population when it comes to energy security. In this sensitive market environment, Voith Turbo’s Actuators & Control Systems product line has earned a legendary reputation. Its products are a benchmark for reliability and availability.

A key component, which results in high-availability, robust hardware and software for the controls of gas and steam turbines, is the attitude of the team: It combines sound professional expertise with a high degree of customer focus and flexibility. For outgoing General Manager Willi Zinnecker and his successor Dr. Boris Voelling, this is an important factor in the company’s success.

Overview of product portfolio

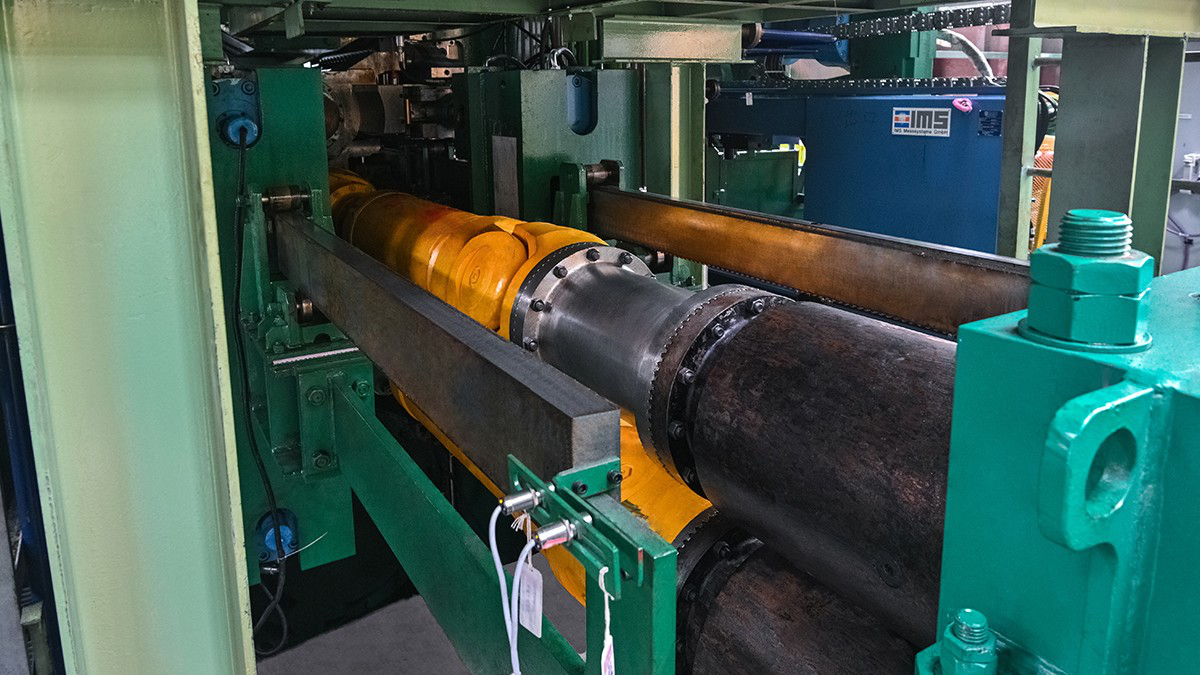

Gas turbines, steam turbines and compressors that use actuators, protection equipment and control systems from Voith Turbo achieve very high efficiency and operational reliability. With our products, virtually all turbine and compressor control systems can be achieved – from simple, non-redundant solutions to high-availability redundant systems.

I/H converters and I/H converter modules

- High productivity thanks to high reliability

- Stable processes due to top-class control characteristics

- Extremely robust: not sensitive to contaminated pilot oil

- Ideal for high-availability systems and facilities: The Mean Time Between Failures (MTBF) is up to 20,000 years

Way valves and way valve modules

- Very good process quality due to highly dynamic and precise controls

- Available as simple (non-redundant) or redundant system

- Ideal for high-availability systems and facilities: The Mean Time Between Failures (MTBF) is up to 8,800 years

Servo motors

- Complete, cost-optimized drive solution with high force density

- Highly dynamic, precise and stable control

- Simple system integration and fast commissioning, also ideal for retrofits

- Integrated fail-safe function

Actuators for protection systems

- In the event of an emergency trip, the actuators ensure that the turbines are switched off safely, typically in 300 milliseconds

- This avoids the damage that occurs in the event of turbine overspeed

- Ideal for high-availability systems and plants: The Mean Time Between Failures (MTBF) is up to 100,000 years

Control systems for steam turbines and other turbomachinery

- Highly flexible control systems for steam turbines of all power classes, even in system-critical applications

- Standard compact controller TurCon DTc, modular design with industry-compliant hardware and a pre-engineered software solution (simply set the parameters)

- Customized controllers TurCon DTe-Rx and -Cx, scalable design with industry-compliant standard hardware (available as non-redundant and redundant solution)

Service, engineering and retrofits

- Services from Voith ensure productivity and efficiency

- Plant and system operators benefit from our product and technology expertise during the entire life cycle of turbines or other systems

- Development of customized solutions based on extensive knowledge of the industry

Installed in 30,000 steam turbines, proven in millions of operating hours

For our customers, actuators and control systems play a key role in the efficient control of their gas and steam turbines: One in three steam turbines worldwide features actuating and control technology from Voith Turbo. You can only achieve this kind of market share if you have earned a top-class reputation. In the energy sector, specifically in power plant engineering, oil and gas and petrochemicals – the most important market segments for actuators and control systems from Voith Turbo – you need to satisfy a large number of criteria to survive. Besides the most important aspect, which is maximum reliability to avoid turbine and thus plant shutdowns, industry and process know-how as well as extensive experience and flexibility are also crucial. “Our team is at home in this challenging market segment,” says Dr. Boris Voelling, General Manager of the Actuators & Control Systems product line at Voith Turbo.

Using products from Voith Turbo, non-redundant and redundant actuators and control systems can be realized. In the case of redundant systems, two equivalent actuators are connected in parallel. One is the lead actuator and the other is in ‘hot standby’. “In the event of a malfunction, the product in hot standby automatically takes the lead and the other product switches off and can be serviced,” says Willi Zinnecker, outgoing General Manager Actuators & Control Systems at Voith Turbo. “What is crucial is that this happens automatically in fractions of a second. We have literally perfected these functions.” And when it comes to reliability, Voith Turbo’s actuators and control systems have earned the status of an industry legend. The Mean Time Between Failures, i.e., the average operating time of a system before a failure occurs, is up to 100,000 years. This value is achieved by the company’s trip block for activating a trip valve.

Products from Voith Turbo are also making nuclear power plants safe

The company’s huge market penetration for steam turbines and the excellent reputation of the products are resulting in more and more inquiries from operators of nuclear power plants. Actuators from Voith Turbo, for example I/H converters or servo motors, are therefore increasingly playing a role in carbon-free power generation. “Operators of nuclear power plants have become one of our most important target groups,” says Dr. Boris Voelling. “Internationally, nuclear power is continuing to play what is an increasingly important role in carbon-free electricity generation. Many industrialized countries are modernizing their power plant inventory to ensure reliable operation while enabling systems to run for longer. At the same time, there is a trend towards building new plants based on new concepts and technologies. Small modular reactors (SMR) are playing an important role in this context. Regardless of the reactor technology, whether established boiling water and pressurized water reactors or SMRs: Our products increase efficiency and safety in all types of nuclear power plants.”

That Voith Turbo’s Actuators & Control Systems product line has gained a foothold even in this perhaps most demanding market segment is also evidenced by the recently won Supplier Excellence Award presented by clients in the USA (see below). “Our customers appreciate us or those values that we put into practice every single day,” says the new General Manager Dr. Boris Voelling, referring not just to product quality but also the caliber of the company’s consultation service and aftermarket support. “Even when the order has long since been processed – we do not leave our customers on their own even after delivery and implementation, but are always approachable, highly flexible, and respond immediately if we are needed.” In this context, the team enjoys support from Voith’s worldwide sites and service workshops.

INNOVATION LEADER

Voith receives Westinghouse Excellence Award for outstanding performance in turbine upgrade project

At the Westinghouse Nuclear Global Supplier Symposium 2024 in Pittsburgh, USA, Voith was chosen from more than 135 suppliers to receive the “Innovation Leader” excellence award. Voith was awarded this distinction for its outstanding achievements in the modernization of the actuators of one of the largest steam turbines in the world in a nuclear power plant in the USA.

What is the value of reliability? Where is the product line Actuators & Control Systems headed? Two experts answer these questions.

Mr. Zinnecker, like scarcely any other brand, Voith is a byword for high or even maximum reliability. In your product line, you and your team have made a very special contribution to this corporate value. The actuators and control systems are a benchmark for availability – generally referred to as uptime. Before you retire, can you tell us how you managed that?

Willi Zinnecker: First of all, it’s due to the fact that we have been dealing with actuators and control systems for decades, and several generations of Voith engineers have continuously developed the technologies. So reliability cannot therefore be tied down to individuals but is the work of the entire team. For each of us, it’s about more than ‘just’ manufacturing extremely reliable products.

It’s about the mindset of wanting to make a difference for the customer. As well as delivering solutions that are almost technically perfect, this also includes, for example, providing customers with some light-bulb insights when we advise them and also offering excellent service – no matter what day or time.

Dr. Voelling, as General Manager, where do you envisage improvement potential in your product line? Can you make the products even more reliable?

Dr. Boris Voelling: Naturally, we always want to improve. With many of the existing products we are already at a level where it would be difficult and would make limited sense to make the technology even more reliable. Reliability is about much more, as Willi Zinnecker already said. Here’s an example: With one of our lighthouse projects which we were recently awarded, the operator of a nuclear power plant submitted an inquiry for the replacement of the system-critical actuators. At the end of our consultations, we had produced a completely new technical concept that was much leaner and less maintenance-intensive. The customer was delighted and would not have questioned the existing solution. It is these kinds of advisory services we mean when we talk about Voith Turbo being a reliable partner. And this also includes a high level of on-time delivery, an accommodating after-sales service, and fast response times if a service should be needed.

In your view, what is the most important benefit of reliability for your customers?

Dr. Boris Voelling: Our products enable operators to have full control over their systems at all times. They can rely on them not causing a breakdown. For people in charge of large power plants or chemical plants, this is an invaluable advantage. It makes the difference as to whether they can sleep soundly or not. So ultimately, we are selling a good night’s sleep.

Willi Zinnecker: Another aspect is that only systems that are running earn money. If there’s a shutdown, nobody is going to praise you for saving a few percentage points when buying components. What they will do is calculate how much money the downtime is costing. Working with Voith Turbo gives companies the reassurance of having opted for the best technology available on the market. This is also valuable, because the turbines and compressors that our products regulate and control require significant investment and are highly susceptible. So you never feel quite comfortable about having opted for the second-best solution. By the way, this is not something that I am asserting – it is feedback that we often get from our customers.

When you look to the future – where is the product line Actuators & Control Systems heading?

Dr. Boris Voelling: On the one hand, further developments are making our products even more sustainable and environmentally friendly. This concerns the switch from electro-hydraulic to electro-mechanical systems. Or the use of hydraulic fluids not derived from crude oil.

Looking at the bigger picture, we envisage great potential for improving the efficiency of turbines and reducing CO2. This is also why we want to win over other nuclear power plants as customers. The focus is not just on new reactors, but above all on existing ones. The buzzword is lifetime extension. Finland, for example, is planning to keep its reactors on the grid for 80 years instead of the originally envisaged 40 years. This will save huge amounts of CO2 and make a major contribution to meeting the set climate targets. In other markets too, there is a trend toward extending service lives. So there’s a lot to be tackled.

Willi Zinnecker: I can underscore all those goals – and wish you every success!