Decarbonization with CCUS:

Reach your net zero target with Voith Turbo.

When it comes to mitigating climate change and reaching the agreed net zero target by 2050, there is no way around decarbonization strategies. On the road to a climate-neutral future, there is no alternative to the capture, use or storage of CO2 in addition to the avoidance. This process is called carbon capture, utilization and storage, or CCUS for short. It is extremely important because despite technological innovations and worldwide efforts, there are still numerous industrial processes in which CO2 emissions are either difficult to avoid or cannot be prevented at all. Voith Turbo not only supports CCUS infrastructures with innovative technologies and reliable products, but also advises and provides guidance on the application of our solutions in CCUS processes.

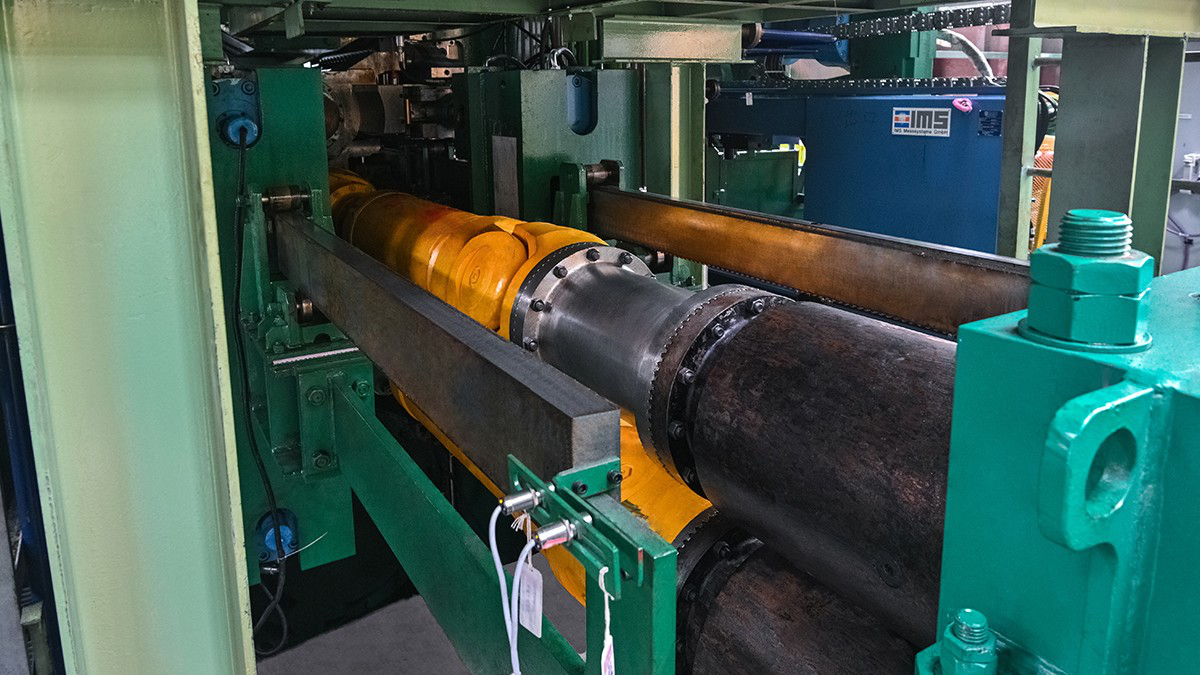

Oil and gas infrastructure with CCUS process implemented

After the CO2 has been collected by capture technology in special scrubbers and absorbers, Voith BHS turbo gear units can help to compress or liquefy it and Voith mechanical variable speed drives (such as the Vorecon technology) can help to transport the CO2.

For the capture and storage of CO2, components from Voith Turbo play an important role worldwide. This applies in particular to Voith BHS turbo gear units such as the integral gearbox. Where single shaft centrifugal compression is considered, Voith Vorecon planetary gear units can help control compressor operation via an electric motor. These products have proven effective over many years of continuous operation worldwide and therefore lay the foundation for a high level of process reliability.

Experts from the R&D department have strong methodological skills in the field of CCUS and have integrated Voith Turbo components into cutting-edge systems that are already preventing CO2 emissions at several locations worldwide, thus mitigating climate change.

The net zero target – i.e. the reduction of CO2 emissions to zero tons – was formulated in the Paris Agreement. A reduction of 45% is to be achieved by 2030, and 90% by 2050. Some regions such as the EU are setting themselves even more stringent targets and are striving to be climate neutral by 2050. In this context, the potential of CCUS plays an important role. Forecasts predict a capture of 1.8 Gt CO2 in 2030 and 7.6 Gt for 2050.

Turbo gear units are at the core of the CCUS process

The expansion of regenerative energies, which are crucial to achieving the net zero target, is forging ahead worldwide. But how do we handle CO2 emitters that cannot be readily decarbonized? This is the case, for example, in oil and gas extraction, cement production, and the chemical industry. Numerous organizations and scientists recommend the CCUS process for these kinds of infrastructures. This involves separating CO2 from the exhaust gas flow and initially, extracting it in scrubbers and absorbers. For further transport and downstream processing and/or carbon capture and storage the gas needs to be compressed. This process can be done reliably and efficiently by various Voith Turbo technologies.

Voith BHS integral gear units:

Reliably successful since 1970

When used in compressor systems, Voith BHS integral gear units offer a high overall efficiency that is only surpassed by their reliability. Both qualities are crucial to the decades-long success story of this type of Voith Turbo gear unit.

The Vorecon planetary gear system: efficiently regulates compressors

Planetary gear systems are used in the CCUS process wherever variable speeds are required. Voith Turbo’s compact Vorecon gear units enable project costs to be minimized and improve reliability.

More than just a component supplier:

Process expertise and service are always part of the package

For Voith Turbo, expertise and partnership are just as important as highly reliable products and efficient technologies. When implementing turbo and planetary gear units for CCUS applications, our experts have benefited above all from their decades of experience. Since 1970, Voith has produced 20,000 of the turbo gear units alone. 7,000 of these are still in use – including hundreds in the energy industry, where downtimes add up to high losses within a short period of time.

This means that alongside the reliability that is always our priority, providing an excellent service is vital. For a highly effective partnership, Voith Turbo relies on a worldwide service network of workshops and specialists as well as the expertise available from Germany. Integrating upgrades into maintenance and repair jobs often helps improve performance and efficiency.

At Voith, we see ourselves as more than mere suppliers of components and products. In the CCUS segment, our experts have established significant methodological capabilities and can provide customers with comprehensive advice and support regarding our solutions.

Never let a customer down:

At Voith Turbo, the spirit of partnership thrives in our worldwide service network. The Competence Center Turbo Gear Units in Sonthofen is also the headquarters of the company’s global service activities. It is home to 60 professionals across various departments including Field Service Engineers and Technicians in our dedicated workshop. Voith Turbo also operates worldwide service hubs to ensure fast response times.

What is the role of CCUS and how can Voith Turbo help?

Two experts answer these questions.

The CCUS market has had to establish itself to earn its place among the tools used to combat global climate change. What has led to the CCUS market gaining in importance worldwide?

Simon Turnbull: When it comes to reducing CO2, many different methods play a role such as renewable energies, general electrification, hydrogen as a climate-neutral energy source, or specifically the electrification of drive systems that were previously powered with fossil fuels. However, CCUS is extremely important when it comes to decarbonizing industries and applications that cannot easily reduce their CO2 emissions. The emergence of CCUS in industrial clusters will also increase its viability.

Alberto Baffa: In recent years it has become increasingly clear that the Net Zero target – requiring the reduction of CO2 emissions by 45% by 2030 and 90% by 2050 – will scarcely be achievable without CCUS. This was an important reason for us to consider how we can also support our customers in this area with both technologies and expertise.

And you have clearly found ways of helping your customers with CCUS applications as well?

Alberto Baffa: The starting point was that we have several products in our range that are also relevant for CCUS applications. We have supplied thousands of Voith BHS turbo gear units and Vorecon planetary gear systems and have earned a reputation for reliability in the energy industry and beyond. Reliability backed by track record proven references are paramount for the project stakeholders, from the OEM to the licencors and of course our investors. And because we have been successfully taking on these challenges for a long time, our customers have great confidence in us.

Simon Turnbull: Due to the emergence of industrial clusters and the transport and storage segment within the CCUS market, we hope this can be an area where our solutions can add value and be of support – the appropriate Voith technology depends on the final compressor or pump technology selection. When supplying variable speed drives our team can provide valuable insights when it comes to drive selection, and our solutions can support the reduction of capital expenditure through the simplification of the drive train.

Where have you already provided support for CCUS infrastructures, and which specific objectives were pursued in these cases?

Alberto Baffa: The planning and implementation of CCUS projects is clearly gaining momentum. We have just successfully delivered a large gearbox for CCUS in the Netherlands and we are active in projects in many different countries spanning from North America to Europe and the Middle East. The CCUS potential is massive, however clear regulations and infrastructures are a precondition to untapping new CCUS projects backed by multi-year investments. We are well prepared and looking forward to them.

Simon Turnbull: We have supported CO2 injection several times on offshore applications, more specifically FPSOs, where no flaring is permitted due to legislation and CO2 must be re-injected into the reservoir. Voith’s Vorecon technology has supported this process requirement by providing variable speed due to varying gas compression and reservoir characteristics. As previously mentioned, the use of the mechanical planetary gearbox with variable speed (VSD) reduces the number of components and provides the reliability to support the process requirements over a long period of time.