Tuesdays, Wednesdays, Thursdays.

And Fridays for the future

Our efforts to reduce CO2 emissions never stop

And Fridays for the future

CO2 emissions are one of the most important fields of action for increasing sustainability. Governments and industry associations have set high goals in this area. With the Low Carbon Paper Mill, we are setting an important course for CO2 reduction in paper production.

100% CO2-neutral paper production

Targeting CO2-neutral paper production by 2030 with the help of digital and efficiency-enhancing applications as well as disruptive technologies and the use of renewable energies

Innovative process technologies

Our innovative process technologies increase the efficiency of paper production – with the potential to reduce the carbon footprint by 20%

Digital solutions

Our digital solutions offer the potential for further reductions of 10%

Electrification of the manufacturing process

Electrification of the manufacturing process, using renewable energy and energy storage, massively improves the carbon footprint of paper manufacturing

New, disruptive technologies

Working on new, disruptive approaches to paper production – with the potential to reduce CO2 emissions by more than 50%

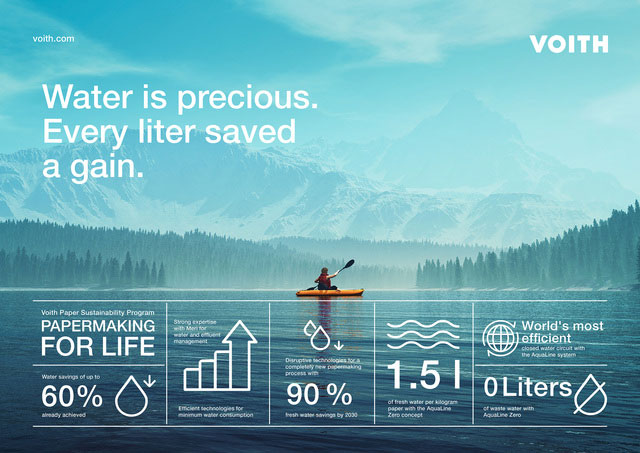

Our technologies

Voith has developed systems and products for all paper grades that effectively save energy along the entire process chain – and also recover and generate energy from renewable sources. Our goal is to cut energy consumption for paper manufacturing in half. This becomes possible both through the use of innovative technologies and the reduction of resource consumption. By increasing the portion of recovered paper, noticeably less power is needed.

Proven success: We make our actions transparent

With this new sustainability report we are once again making our actions transparent. After all, our stakeholders decide whether our sustainability measures are successful: Their assessment forms the benchmark for our actions, as this reflects the effectiveness of our activities in the respective fields of action.

Would you like to learn more about holistic sustainability in paper production? Talk to our experts.

Peter Eisen

Senior Vice Product Management Digital Voith Paper

Bernd Güldenberg

Senior Vice President R&D Technology Voith Paper